Packaging film for multilayer co-extruding urine bag and production method thereof

A multi-layer co-extrusion and packaging film technology, applied in the field of packaging film, can solve the problems of dioxin environmental impact, poor barrier property, building erosion, etc., to expand the heat sealing temperature range, improve stress cracking resistance, and excellent cold resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

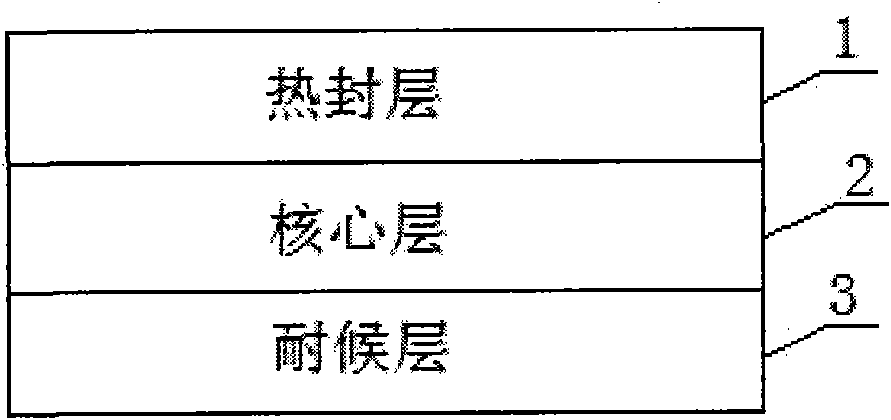

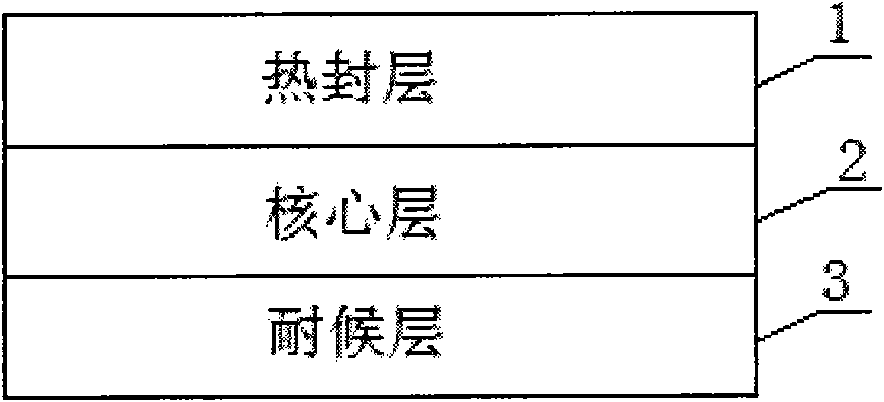

[0028] see figure 1 As shown, a packaging film for a multi-layer co-extruded urine bag includes a three-layer structure of a heat-sealing layer 1, a core layer 2 and a weather-resistant layer 3 arranged in sequence.

[0029] Further, a mixture of ethylene-vinyl acetate copolymer (EVA), ultra-low-density polyethylene (ULDPE), and ethylene-acrylic acid copolymer (EAA) is selected as the heat-sealing layer 1, and the low-density polyethylene (ULDPE) ) and ethylene-acrylic acid copolymer (EAA) are added in an amount of 10% to 30% in the heat-sealing layer 1 mixture, the melt index of the mixture is 1.0 to 4.0g / 10min, and the density is 0.88 to 0.94g / 10min. cm 3 .

[0030] Further, a mixture of ethylene-vinyl acetate copolymer (EVA), ultra-low density polyethylene (ULDPE), ethylene-acrylic acid copolymer (EAA) and ethylene-methacrylic acid copolymer (EMAA) is selected as the core layer 2, And the addition amount of the ultra-low density polyethylene resin (ULDPE), ethylene-acryl...

Embodiment 2

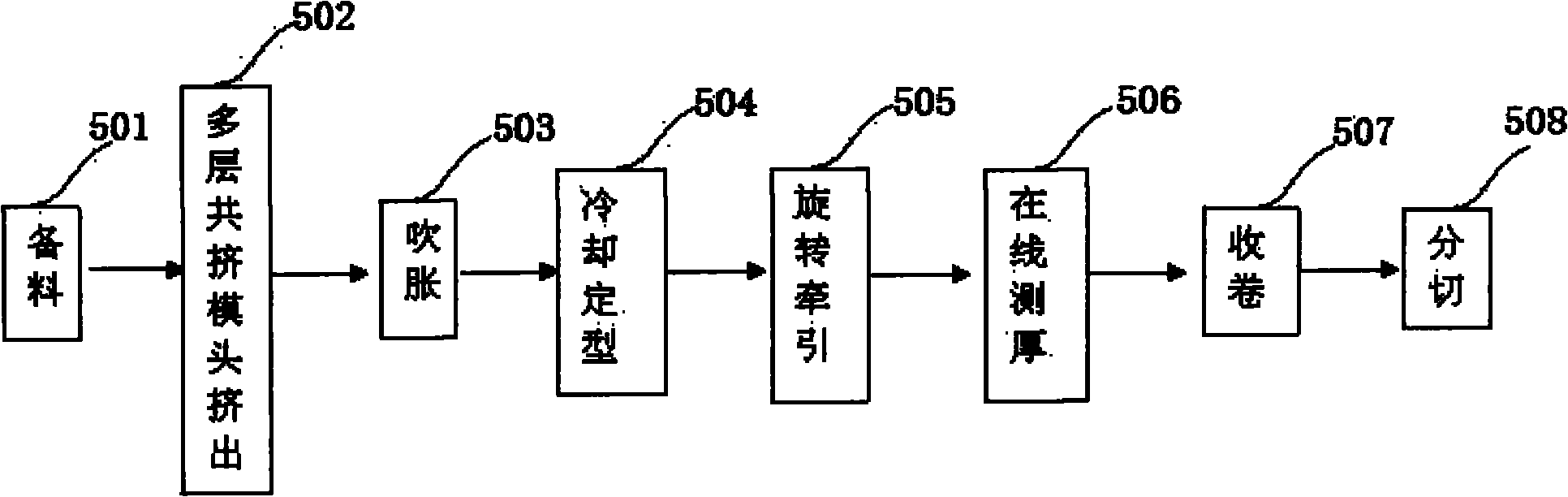

[0034] see figure 2 Shown, a kind of method for preparing above-mentioned multilayer co-extruded urine bag packaging film comprises the following steps:

[0035] 501) material preparation;

[0036] 502) multi-layer co-extrusion die extrusion;

[0037] 503) inflation;

[0038] 504) cooling and shaping;

[0039] 505) rotary traction;

[0040] 506) Online thickness measurement

[0041] 507) winding;

[0042] 508) Slitting.

[0043] Preferably, the inflation method used in step inflation 503 is blowing on multi-layer co-extrusion blowing equipment, and the inflation ratio is between 1.5-3.

[0044] Preferably, the cooling setting adopted in step cooling setting 504 is an air-cooling cooling setting method.

[0045] Further, the online thickness measurement device of the multi-layer co-extrusion blowing equipment is installed above the foam stabilization support, on the ring support, and adopts non-contact automatic film thickness measurement, display, tracking and feedbac...

Embodiment 3

[0047] see figure 2 Shown, a kind of method for preparing above-mentioned multilayer co-extruded urine bag packaging film comprises the following steps:

[0048] 501) material preparation;

[0049] 502) multi-layer co-extrusion die extrusion;

[0050] 503) inflation;

[0051] 504) cooling and shaping;

[0052] 505) rotary traction;

[0053] 506) Online thickness measurement

[0054] 507) winding;

[0055] 508) Slitting.

[0056] Preferably, the inflation method used in step inflation 503 is multi-layer co-extrusion down-blowing, and the inflation ratio needs to be controlled between 1-2 when blowing under multi-layer co-extrusion down-blowing equipment.

[0057] Preferably, the cooling setting adopted in step cooling setting 504 is a water-cooling cooling setting method.

[0058] Further, the online thickness measuring device of the multi-layer co-extrusion down-blowing equipment is installed at the exit position of a traction pressure roller or after the lateral deviat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com