Mechanical regeneration method for rubber burrs

A flash and mechanical technology, which is applied in the field of recycling and utilization of product flash waste after rubber vulcanization, to achieve the effect of reasonable process, good performance and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Flash regeneration process of styrene-butadiene rubber.

[0018] Step 1: Sorting styrene-butadiene rubber from the rubber flash, first removing iron filings and impurities, and then classifying according to the hardness grade with 10 degrees as grade 1;

[0019] The second step: the crushing of rubber flash. Put the styrene-butadiene rubber of the same hardness level into the crusher for crushing. According to the model CSJ-400A of the crusher, the amount of each input is 300 grams. The temperature of the crusher needs to be Control it below 100°C. When the temperature is higher than 100°C, turn on the cooling water for cooling, and the crushed flash powder is also classified and stored.

[0020] The third step: mechanical treatment of rubber flash. First heat the crushed flash at 100°C for 20 minutes, and then carry out thin pass extrusion on the mill. The temperature of the rollers of the mill is controlled at 80°C±10°C. The roller distance of the mill ...

Embodiment 2

[0022] Embodiment 2: the flash regeneration process of nitrile rubber.

[0023] Step 1: Sorting out the nitrile rubber from the rubber flash, first remove the iron filings and impurities, and then classify according to the hardness grade with 10 degrees as grade 1;

[0024] The second step: the crushing of rubber flash, put the nitrile rubber of the same hardness level into the crusher for crushing, the amount of each input is 300 grams, the temperature of the crusher must be controlled below 100 ℃, the temperature is higher than At 100°C, turn on the cooling water for cooling, and the crushed flash powder is also classified and stored.

[0025] The third step: mechanical treatment of rubber flash. First heat the crushed flash at 100°C for 20 minutes, and then carry out thin pass extrusion on the mill. The temperature of the rollers of the mill is controlled at 80°C±10°C. The roller distance of the mill is Adjust it to 0.15mm±0.08mm, and the weight of the flash edge for each...

Embodiment 3

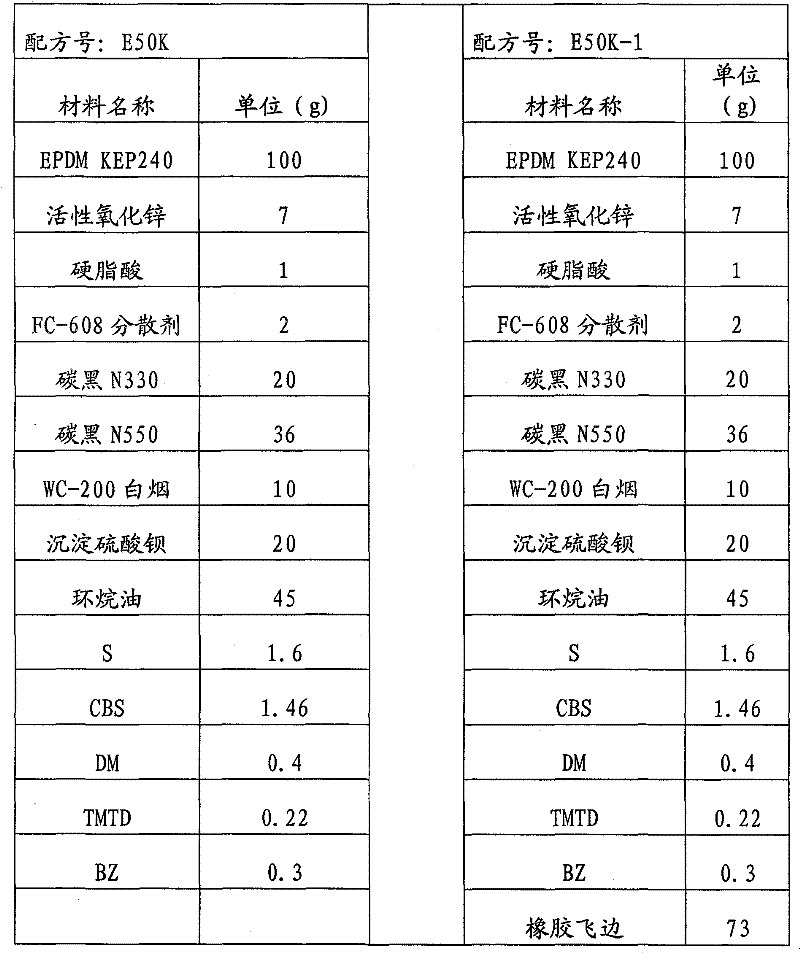

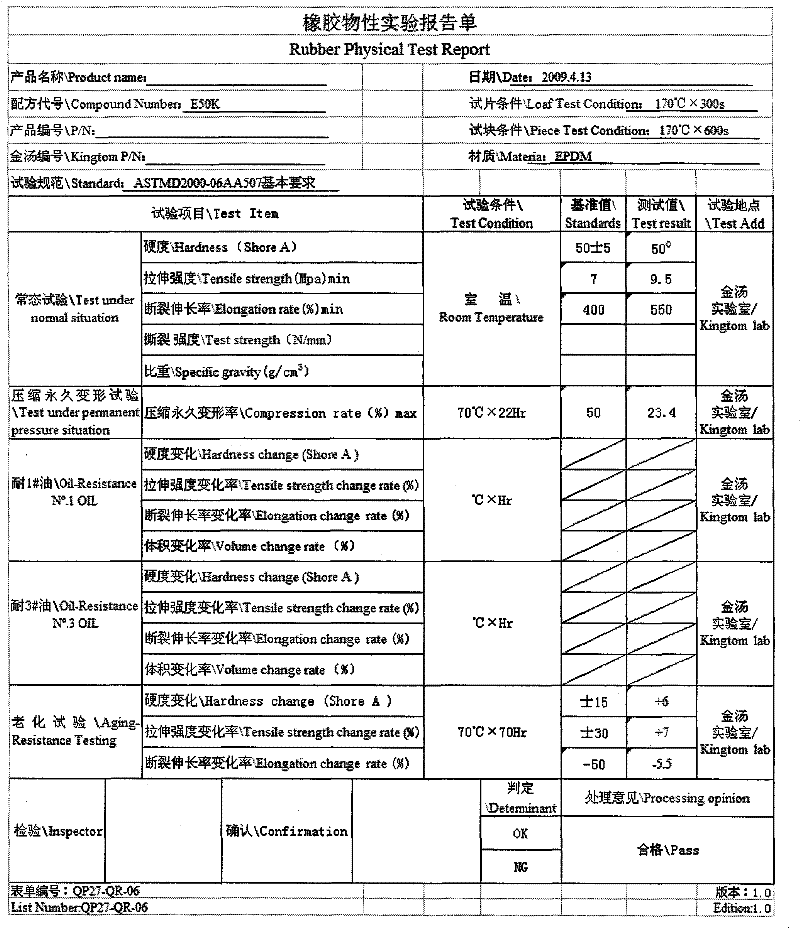

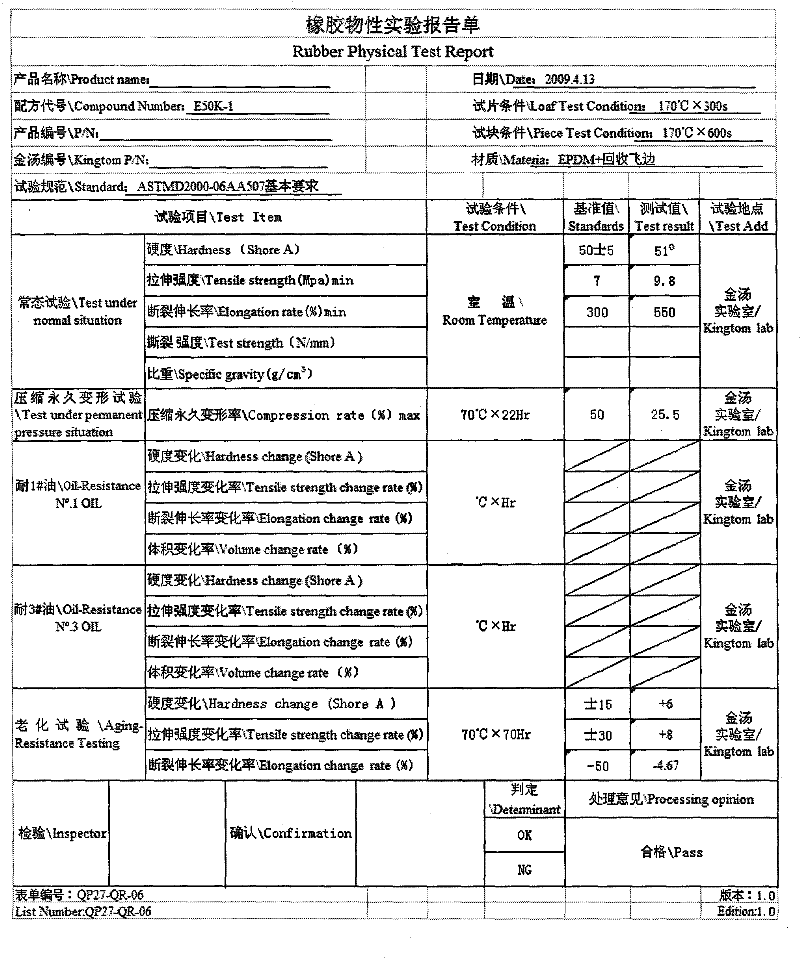

[0027] Embodiment 3: Flash regeneration process of EPDM rubber.

[0028] Step 1: Sorting out the EPDM rubber from the rubber flash, firstly remove the iron filings and impurities, and then classify according to the hardness level with 10 degrees as 1st grade;

[0029] The second step: the crushing of rubber flash. Put the EPDM rubber of the same hardness level into the crusher for crushing. The amount of each input is 300 grams. When the temperature is higher than 100°C, turn on the cooling water for cooling, and the crushed rubber flash powder is also classified and stored.

[0030] The third step: mechanical treatment of rubber flash. First heat the crushed flash at 100°C for 20 minutes, and then carry out thin pass extrusion on the mill. The temperature of the rollers of the mill is controlled at 80°C±10°C. The roller distance of the mill is Adjust to 0.15mm±0.08mm, the weight of the rubber flash for thin-pass extrusion is 8kg each time, add 2 grams of stearic acid for ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com