Hanging drop protection cover automatic separation device and method

A technology of automatic separation and suspension device, which is used in measurement devices, engine testing, instruments, etc., which can solve the problem of inability to realize the research on the evaporation and combustion characteristics of tiny droplets, the inability to accurately simulate droplet evaporation, and increase the initial temperature of fuel, etc. problems, to achieve the effect of being conducive to repeatable experimental analysis, avoiding experimental errors, and small internal heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the following embodiments are only used to illustrate the present invention, not to limit the present invention.

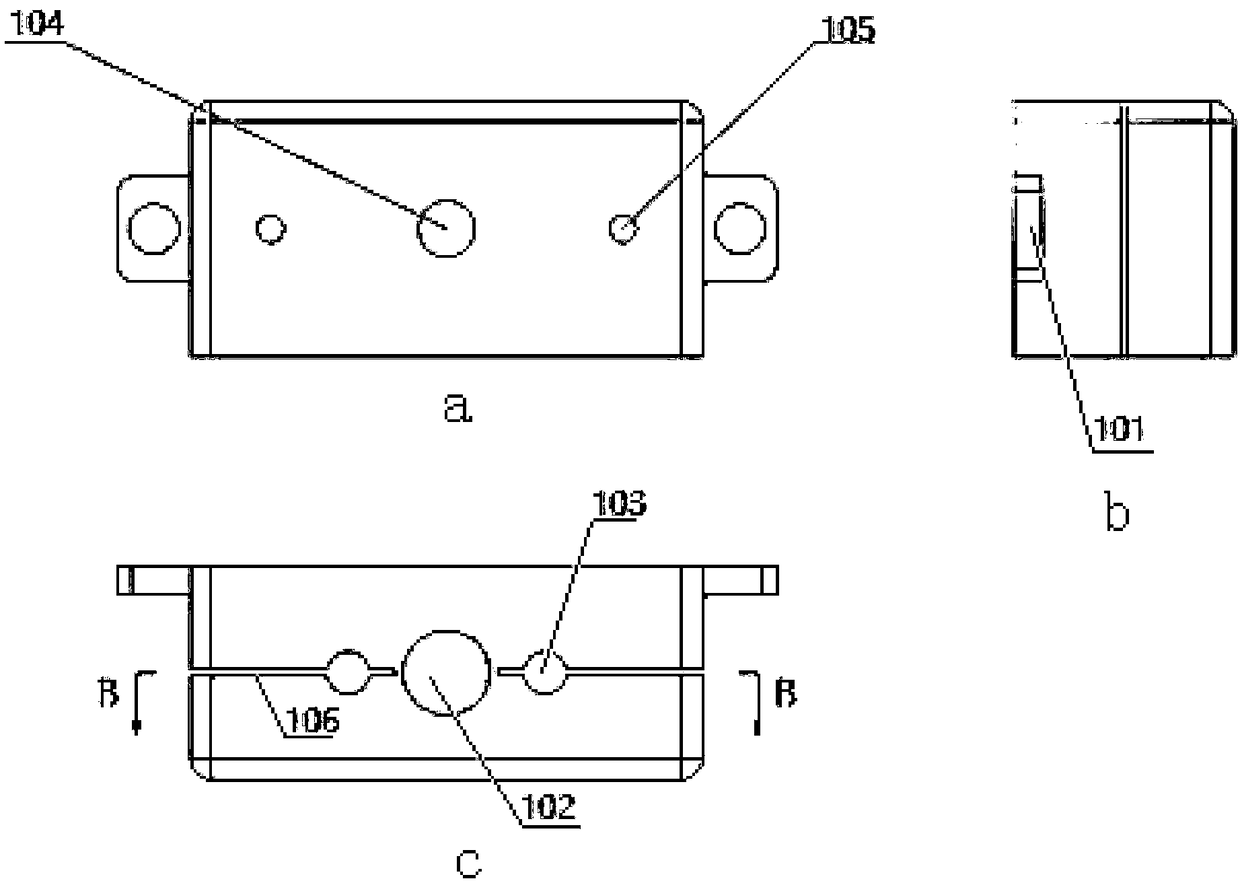

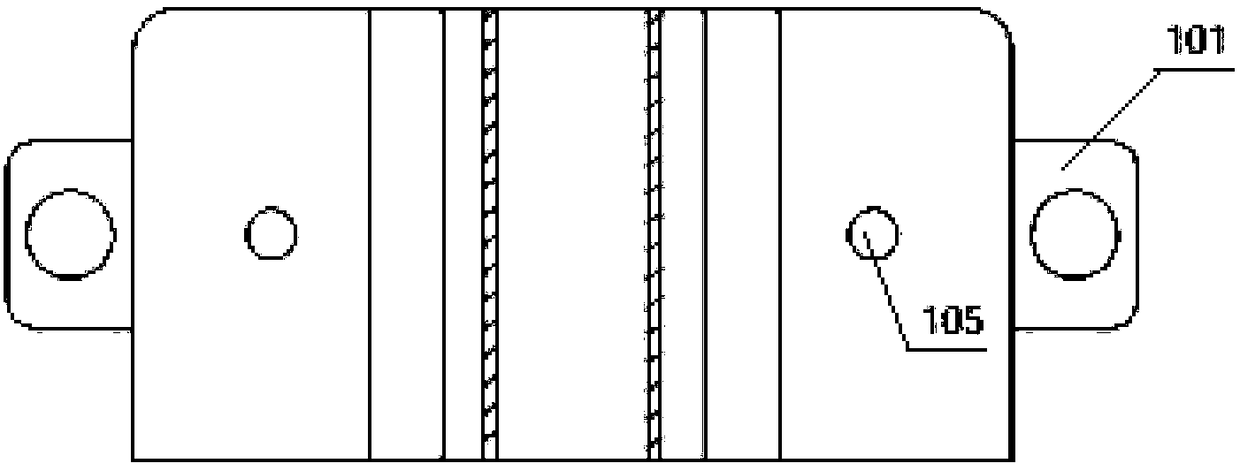

[0031] An automatic separation device for a suspended droplet protection cover, comprising a clamp body 1, a suspension device 2, a protective cover connecting rod 3, an inlet plate 4 and a quartz glass cover 5. like figure 1 and figure 2 As shown, the left and right sides of the clamp body 1 are provided with lugs 101 for fixing the clamp body 1 and the entire drip device; the upper and lower surfaces of the clamp body 1 are provided with a middle through hole 102 and two side through holes 103, and the front side A fastening hole 104 and two adjustment holes 105 are provided; grooves 106 are arranged on both sides of the side through hole 103 ; the width of the groove 106 is smaller than the diameter of the side through hole 103 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com