High-temperature solid foam draining agent and preparation method

A technology of high-temperature solids and foam discharge agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of unsuitable gas wells, inconvenient storage and filling, and poor drainage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention will be further described below in conjunction with examples: a high-temperature solid foam discharge agent, which is composed of alkyl sulfate, ammonium lauryl sulfate C 12 H 25 SO 4 NH 4 , Stearic acid C 18 H 36 O 2 , sodium carbonate Na 2 CO 3 and water composition, their weight percentages are: alkyl sulfate 20% to 30%, ammonium lauryl sulfate C 12 H 25 SO 4 NH 4 10%~15%, Stearic acid C 18 H 36 O 2 25%~35%, sodium carbonate Na 2 CO 3 8%~12%, the rest is water;

[0022] A preparation method of a high temperature solid foam discharge agent:

[0023] (1) Weigh 20% to 30% of alkyl sulfate and 10% to 15% of ammonium lauryl sulfate C respectively. 12 H 25 SO 4 NH 4 , 25% to 35% stearic acid C 18 H 36 O 2 , 8%~12% sodium carbonate Na 2 CO 3 ; the rest is water;

[0024] (2) Alkyl sulfate, ammonium lauryl sulfate C 12 H 25 SO 4 NH 4 Add them to the reaction kettle respecti...

Embodiment 1

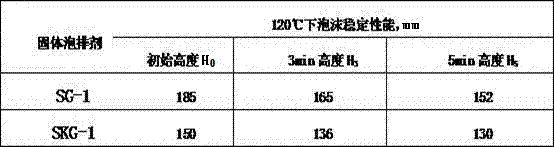

[0031] Example 1: This example provides a gas well high temperature solid foam discharge agent SG-1.

[0032] SG-1 type high temperature solid foam discharge agent, it is composed of sodium lauryl sulfate C 12 H 25 SO 4 Na, ammonium lauryl sulfate C 12 H 25 SO 4 NH 4 , Stearic acid C 18 H 36 O 2 , sodium carbonate Na 2 CO 3 and water composition, their weight percentages are: Sodium Lauryl Sulfate C 12 H 25 SO 4 Na30%, Ammonium Lauryl Sulfate C12 H 25 SO 4 NH 4 15%, Stearic Acid C 18 H 36 O 2 25%, sodium carbonate Na 2 CO 3 8%, the rest is water;

[0033] (1) Weigh sodium lauryl sulfate C with a weight ratio of 30% respectively 12 H 25 SO 4 Na, 15% Ammonium Lauryl Sulfate C 12 H 25 SO 4 NH 4 , 25% stearic acid C 18 H 36 O 2 , 8% sodium carbonate Na 2 CO 3 ; the rest is water;

[0034] (2) Sodium lauryl sulfate C 12 H 25 SO 4 Na, ammonium lauryl sulfate C 12 H 25 SO 4 NH 4 Add them to the reaction kettle respectively, stir for 2h, the st...

Embodiment 2

[0040] Example 2: This example provides a high temperature solid foam discharge agent SKG-1 for gas wells.

[0041] SKG-1 type high temperature solid foam discharge agent, it is composed of sodium lauryl sulfate C 12 H 25 SO 4 Na, C 13~16 Sodium Fatty Alcohol Sulfate C 13~16 H 27~33 SO 4 Na, ammonium lauryl sulfate C 12 H 25 SO 4 NH 4 , Stearic acid C 18 H 36 O 2 , sodium carbonate Na 2 CO 3 and water composition, their weight percentages are: Sodium Lauryl Sulfate C 12 H 25 SO 4 Na10%, C 13~16 Sodium Fatty Alcohol Sulfate C 13~16 H 27~33 SO 4 Na10%, Ammonium Lauryl Sulfate C 12 H 25 SO 4 NH 4 10%, stearic acid C 18 H 36 O 2 35%, sodium carbonate Na 2 CO 3 12%, the rest is water;

[0042] The preparation method of SKG-1 type high temperature solid foam discharge agent:

[0043] (1) Weigh sodium lauryl sulfate C with a weight ratio of 10% respectively 12 H 25 SO 4 Na, 10% C 13~16 Sodium Fatty Alcohol Sulfate C 13~16 H 27~33 SO 4 Na, 10% Amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com