Brazing method for porous ceramic and metal

A technology of porous ceramics and brazing method, which is applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as cracks and reduce the strength of brazed joints, and achieve the effects of improving performance, excellent mechanical properties, and good filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

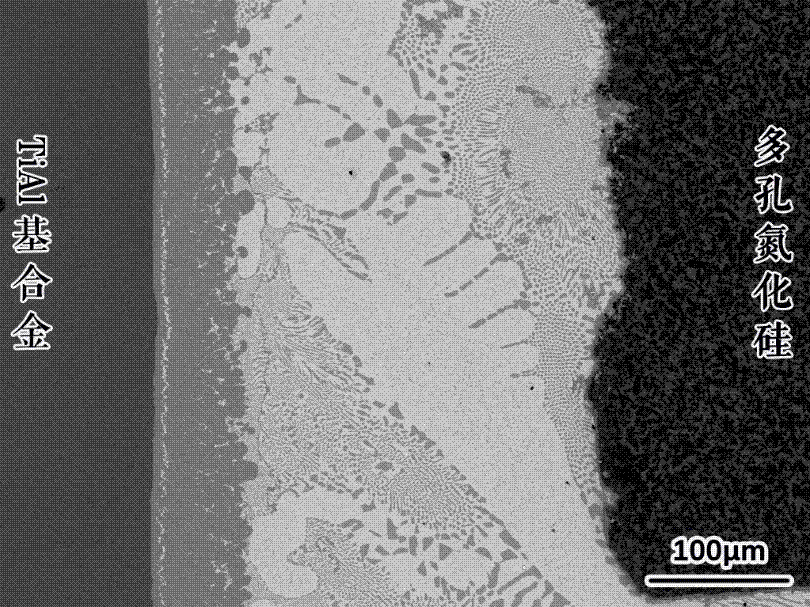

Image

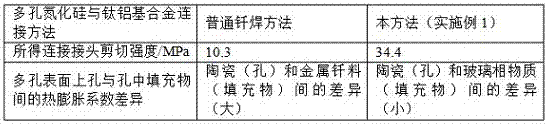

Examples

Embodiment 1

[0046] Step 1. Select a porous silicon nitride ceramic substrate with a porosity of 45%, and use 200#, 400#, 800# SiC sandpaper to grind it step by step from coarse to fine until the surface is smooth and smooth. After polishing, put it into an acetone solution for ultrasonic cleaning 15-30 min. After cleaning, put it into a drying oven and dry at 50-100 °C for 6-10 h.

[0047] Step 2. Mix yttrium oxide powder, silicon oxide powder, aluminum oxide powder and nano-Si3N4 particles in a certain proportion, wherein the size of nano-Si3N4 particles is 20-50 nm, the mass fraction is 10wt.%, Y2O3, SiO2, Al2O3 In the raw material powder, the mass ratio of each substance is Y2O3:SiO2:Al2O3=(3~6):(2~3):(2~3), and the mechanical ball milling is carried out for 8~12 h, and the acetone solution is used as the medium to make the densification coating.

[0048] Step 3: Spray the prepared densified coating evenly on the surface of the pretreated porous silicon nitride ceramics with a pneumat...

Embodiment 2

[0054] Example 2: Step 1. Select a porous silicon nitride ceramic substrate with a porosity of 60%, and use 200#, 400#, 800# SiC sandpaper to grind step by step from coarse to fine until the surface is smooth and smooth, and then put in acetone after polishing Ultrasonic cleaning in the solution for 15~30min, after cleaning, put it in a drying oven, and dry it at 50 ℃~100 ℃ for 6~10 h;

[0055] Step 2. Mix yttrium oxide powder, silicon oxide powder, aluminum oxide powder and nano-Si3N4 particles in a certain proportion, wherein the size of nano-Si3N4 particles is 20-50 nm, the mass fraction is 20 wt.%, Y2O3, SiO2, In the Al2O3 raw material powder, the mass ratio of each substance is Y2O3:SiO2:Al2O3=(3~6):(2~3):(2~3), and the mechanical ball milling is carried out for 8~12 h, and the acetone solution is used as the medium to make a dense chemical coating,

[0056] Step 3: Use a pneumatic atomizing spray gun to uniformly spray the prepared densified coating on the surface of th...

Embodiment 3

[0063] The difference between this embodiment and embodiment 1 is that the porosity of the porous silicon nitride in step 1 is 50%. Other steps are identical with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com