Method for preparing lithium ion battery anode material with core-shell structure

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as poor storage performance, difficult industrialization, and difficult control of metering ratio, and achieve storage performance and safety performance. The process is easy to control and the production cycle is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 100g lithium-ion battery cathode material LiNi 0.8 co 0.15 Al 0.05 o 2, add to the prepared 200ml30wt.% magnesium nitrate solution, and stir to disperse, then slowly add 80ml of acetone to the solution, after reacting for 30min, filter under reduced pressure, and the obtained filter cake is roasted at 400°C for 3h in an air atmosphere, namely 2wt.% MgO shell, 98wt.% LiNi 0.8 co 0.15 Al 0.05 o 2 It is a core-shell structure cathode material for the core.

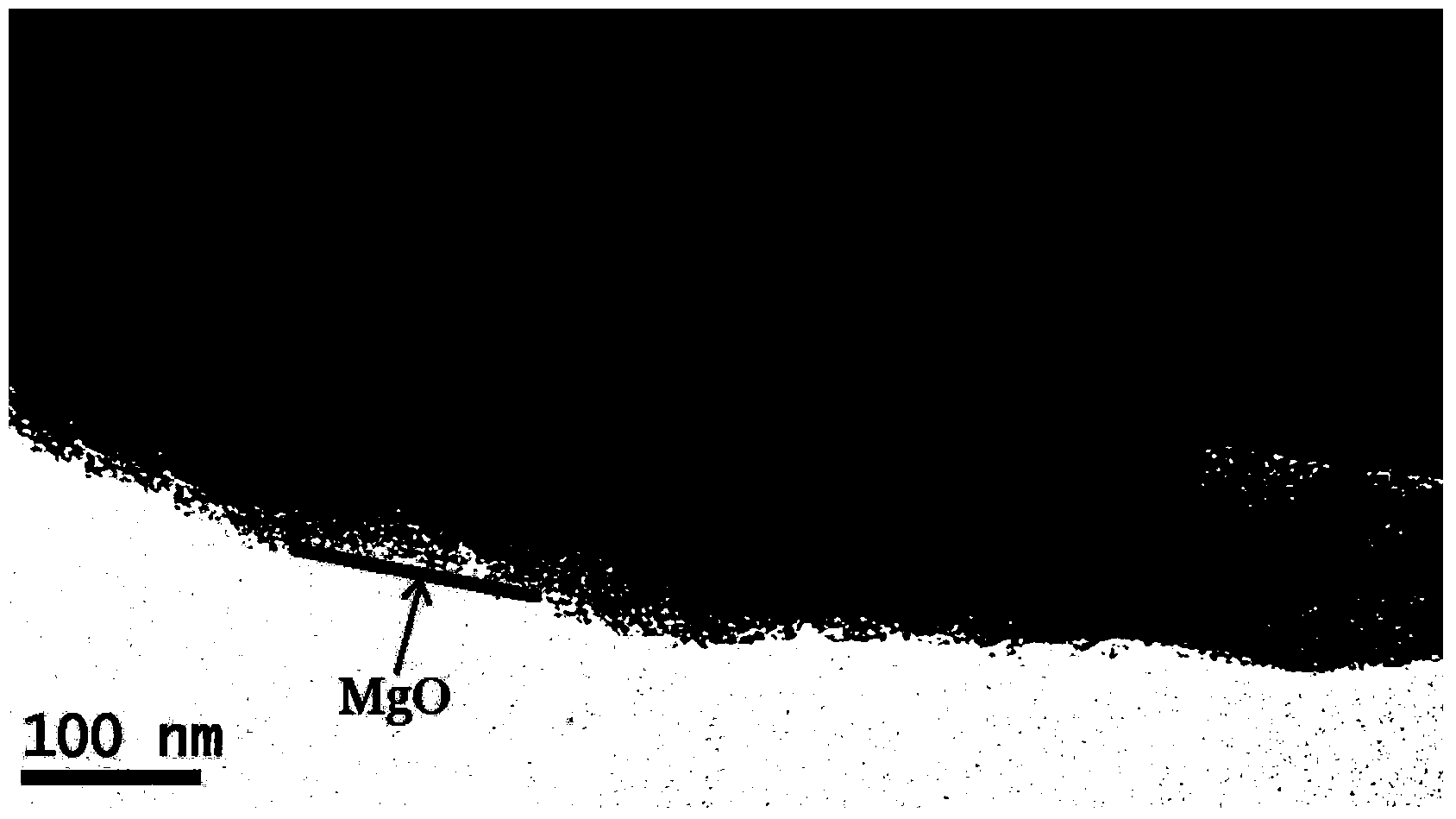

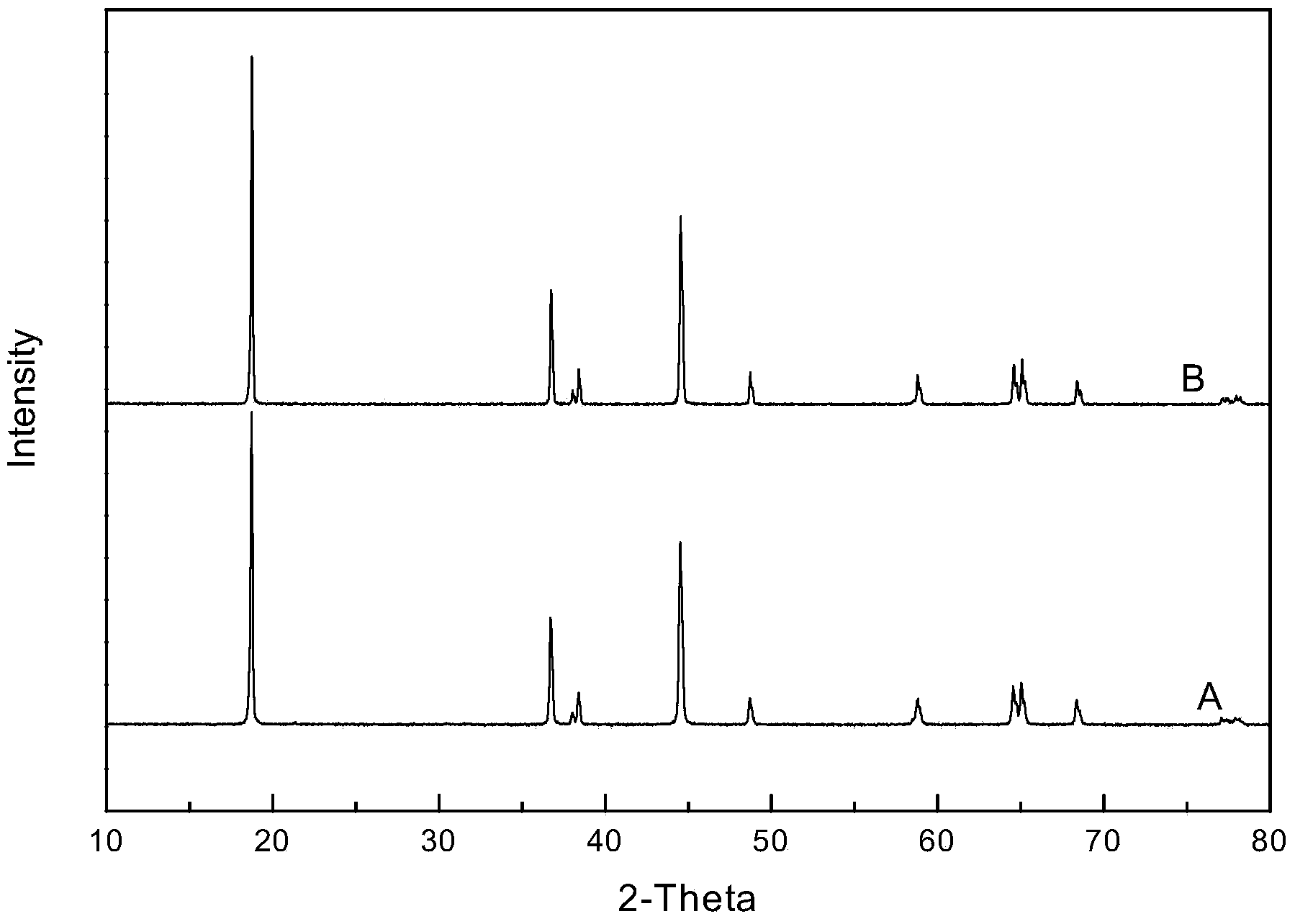

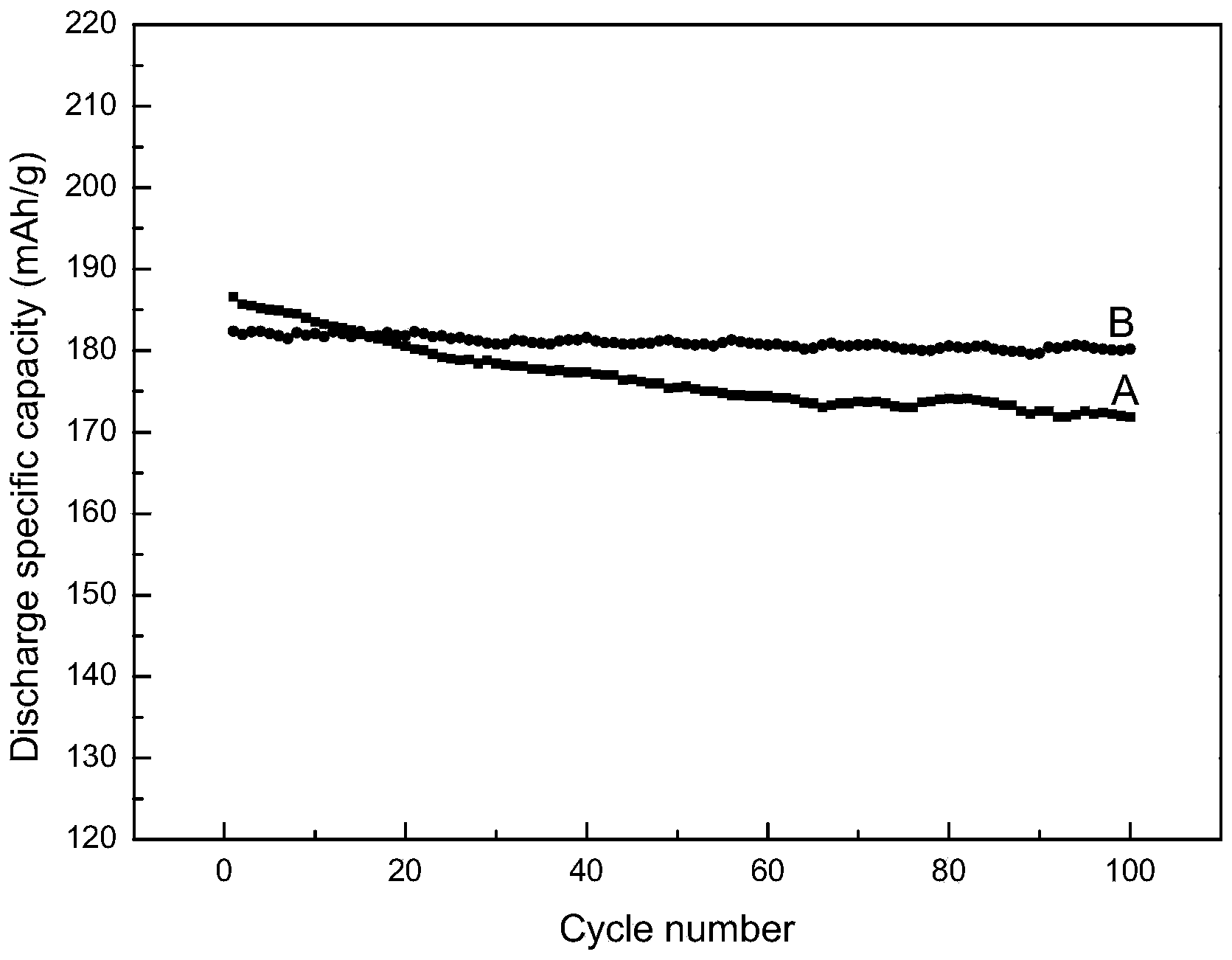

[0033] 2wt.%MgO-98wt.%LiNi 0.8 co 0.15 Al 0.05 o 2 TEM images of the core-shell material figure 1 As shown, the visible shell thickness is about 100nm, and the core-shell structure of the material is distinct. LiNi 0.8 co 0.15 Al 0.05 o 2 Core material with 2wt.% MgO-98wt.% LiNi 0.8 co 0.15 Al 0.05 o 2 The XRD pattern of the core-shell material is as follows figure 2 As shown, it can be seen that the presence of the shell material does not change the structure of the core material. LiNi 0....

Embodiment 2

[0035] Weigh 100g lithium-ion battery cathode material LiNi 0.8 co 0.15 Al 0.05 o 2 , add to the prepared 200ml40wt.% magnesium nitrate solution, and stir to disperse, then slowly add 120ml of acetone to the solution, after reacting for 60min, filter under reduced pressure, and the obtained filter cake is roasted at 500°C for 4h in an air atmosphere, namely With MgO as the shell, LiNi 0.8 co 0.15 Al 0.05 o 2 It is a core-shell structure cathode material for the core.

Embodiment 3

[0037] Weigh 100g lithium-ion battery cathode material LiNi 0.8 co 0.15 Al 0.05 o 2 , add to the prepared 300ml 50wt.% zinc sulfate solution, and stir to disperse, then slowly add 150ml methanol to the solution, after reacting for 90min, filter under reduced pressure, and the obtained filter cake is roasted at 800°C for 2h in an oxygen atmosphere, namely With ZnO as the shell, LiNi 0.8 co 0.15 Al 0.05 o 2 It is a core-shell structure cathode material for the core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com