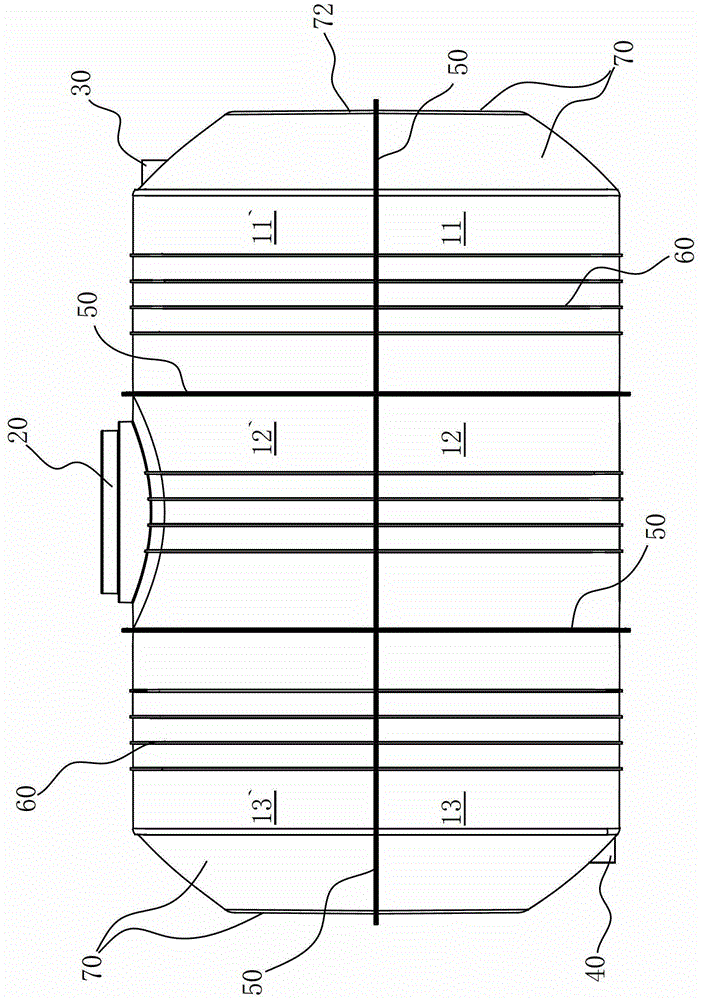

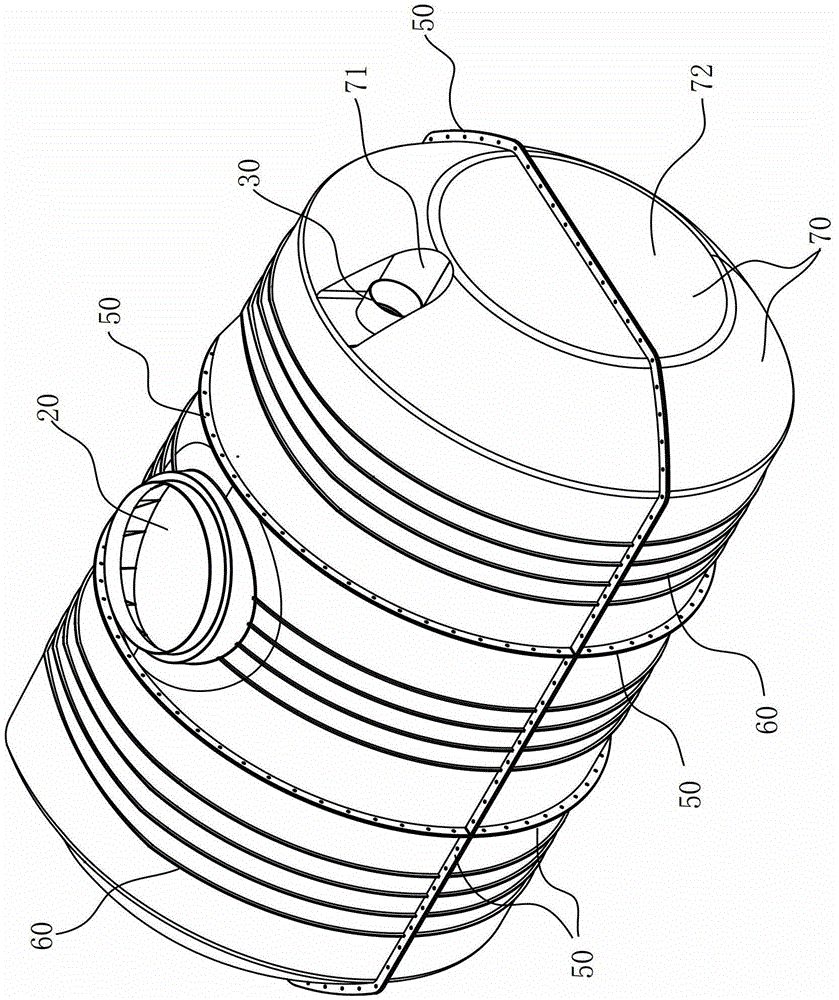

Anti-corrosion, oil-resistant and flame-retardant plastic oil tank

A corrosion-resistant, oil tank technology, applied in the field of reinforced plastics, can solve the problems of difficult quality control, long manufacturing cycle, difficult transportation, hoisting, etc., and achieve the effects of shortening the production cycle, improving impact resistance, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of aforementioned plastics, the step comprises:

[0044] a. Nano-silica is coated with a silane coupling agent as organic silicon;

[0045]b. Add raw materials other than reinforcing fibers to the unsaturated polyester, and mix evenly with a mixer to obtain unsaturated polyester mass molding compound resin paste;

[0046] c. Soak the prepared resin paste in the kneader to reinforce the fiber, and add the fiber within 5 minutes. After kneading for 10-20 minutes, let it fully mix;

[0047] d. Extrude the dough soaked with reinforcing fibers with an extruder, seal and pack it with a polyethylene film, and place it at room temperature for 24 hours to obtain an unsaturated polyester fiber reinforced dough molding compound.

[0048] It is those skilled in the art that can be implemented according to the prior art as for further manufacturing component group with plastics. The prefabricated parts are then connected to form the oil tank.

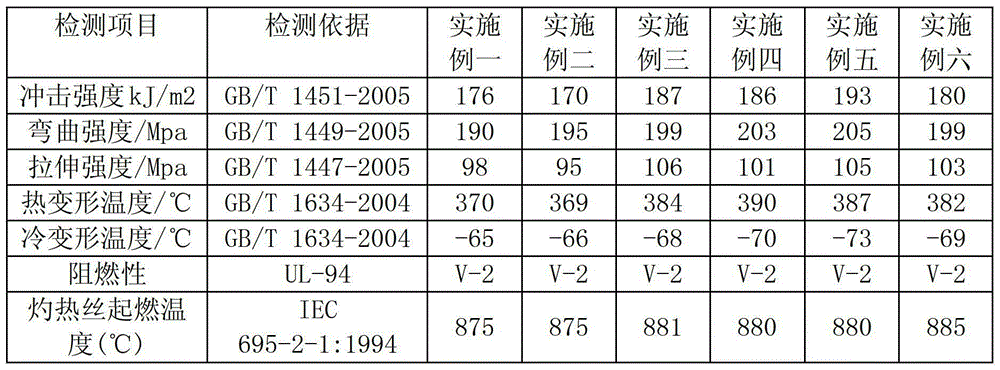

Embodiment 1

[0051] Formula according to weight ratio: 35 parts of tetrahydrophthalic anhydride-propylene glycol unsaturated polyester, 0.3 part of cobalt naphthenate, 0.3 part of methyl ethyl ketone peroxide, 45 parts of calcium carbonate, antistatic agent: 0.1 part of quaternary ammonium salt, antistatic Oxygen agent 1010: 0.1 part, pentabromophenol 0.1 part, microencapsulated tris-(2,3-dibromopropyl) isocyanurate 0.2 part, melamine 0.2 part, nano silicon dioxide 0.09 part, silane coupling agent 0.005 copies;

[0052] Preparation steps:

[0053] Coating nano-silica with a silane coupling agent;

[0054] Add the raw materials into the unsaturated polyester, and mix evenly with a mixer to obtain the unsaturated polyester mass molding compound resin paste;

[0055] The prepared resin paste is impregnated with 28 parts by weight of non-alkali non-twisted glass roving in a kneader, and the glass roving is added within 5 minutes, kneaded for 15 minutes and mixed evenly.

[0056] Extrude the...

Embodiment 2

[0058] Formula according to weight ratio: 45 parts of phthalic anhydride-propylene glycol unsaturated polyester, 0.4 part of cobalt naphthenate, 0.35 part of methyl ethyl ketone peroxide, 47 parts of calcium carbonate, antistatic agent: 0.3 part of phosphate, antioxidant 1076 : 0.12 parts, 0.14 parts of pentabromophenol, 0.3 parts of microencapsulated tris-(2,3-dibromopropyl) isocyanurate, 0.1 parts of melamine, 0.08 parts of nano-silica, 0.008 parts of silane coupling agent;

[0059] 30 parts by weight carbon fiber;

[0060] The preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com