High temperature resistant chloroprene rubber and preparation method thereof

A chloroprene rubber and high temperature resistance technology, applied in the field of rubber materials, can solve problems such as poor high temperature resistance, and achieve the effects of stable physical properties and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

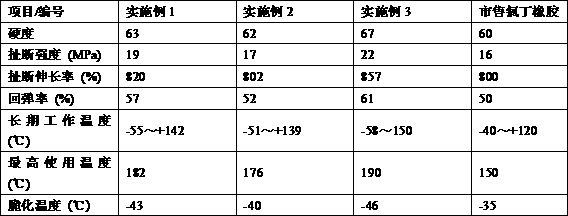

Examples

Embodiment 1

[0022] A high temperature resistant chloroprene rubber, prepared from the following raw materials in parts by weight: 100 parts of chloroprene rubber, 5 parts of magnesium oxide, 0.4 part of stearic acid, 5 parts of zinc oxide, 2 parts of vulcanization retarder, trioxide 0.35 parts of lead, 2 parts of octylated diphenylamine, and 2 parts of phosphate ester.

[0023] The preparation steps are as follows:

[0024] Put the natural rubber and carbon black into the open mill for kneading, add anti-aging agent, mix evenly, and prepare the mixture. The mixture is heat-treated for 7-12 minutes on a high-temperature hot roller at 120°C-160°C. Cool to room temperature, the cooling time is 9-11h, add magnesium oxide, stearic acid, zinc oxide, vulcanization retarder, trilead tetroxide, octylated diphenylamine, phosphate ester on the open mill at room temperature to make rubber.

Embodiment 2

[0026] A high-temperature-resistant chloroprene rubber, prepared from the following raw materials in parts by weight: 100 parts of chloroprene rubber, 4 parts of magnesium oxide, 0.3 parts of stearic acid, 4 parts of zinc oxide, 1 part of vulcanization retarder, trioxide 0.34 parts of lead, 1 part of octylated diphenylamine, and 1 part of phosphate ester.

[0027] According to the same method as in Example 1, high temperature resistant chloroprene rubber was prepared.

Embodiment 3

[0029] A high temperature resistant chloroprene rubber, prepared from the following raw materials in parts by weight: 100 parts of chloroprene rubber, 5 parts of magnesium oxide, 0.5 part of stearic acid, 6 parts of zinc oxide, 3 parts of vulcanization retarder, trioxide 0.36 parts of lead, 3 parts of octylated diphenylamine, and 3 parts of phosphoric acid ester.

[0030] According to the same method as in Example 1, high temperature resistant chloroprene rubber was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com