A kind of polycarboxylic acid type wet mix mortar plasticizer and preparation method thereof

A wet-mixed mortar and polycarboxylic acid technology, applied in the field of building materials, can solve the problems of poor plastic retention, low compressive strength of mortar, flocculent precipitation, etc., achieve good plastic retention, improve bond strength and workability , the effect of physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

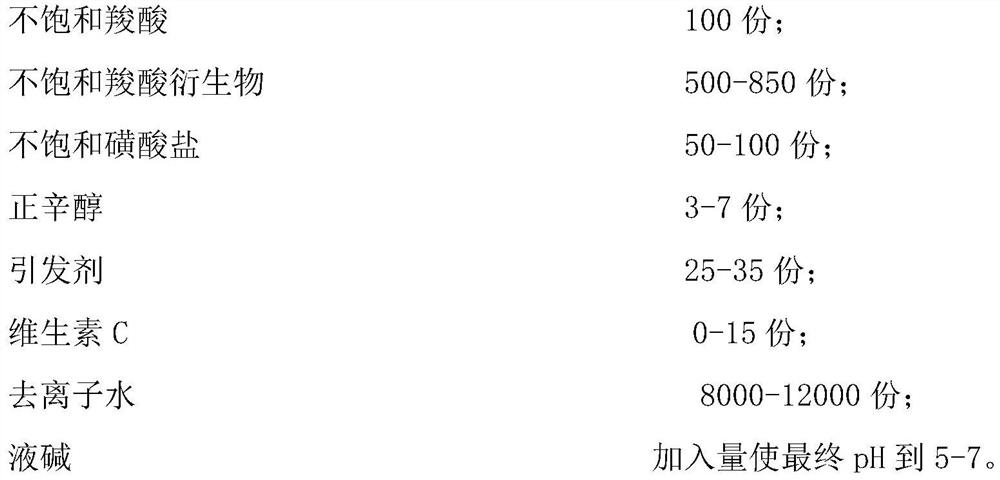

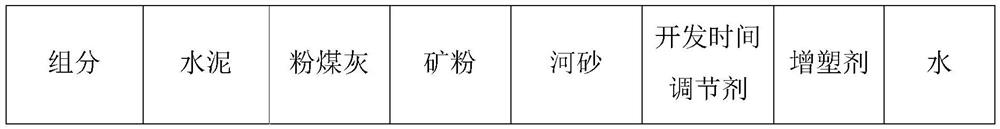

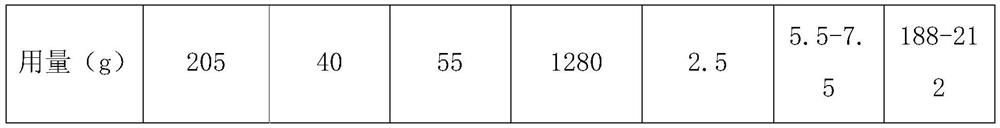

[0016] The preparation of embodiment 1 polycarboxylic acid type wet-mix mortar plasticizer

[0017] First, 766.7 parts of acrylamide and 10,000 parts of deionized water are added to the reactor in a certain proportion. The temperature was then controlled at 30°C under constant stirring. Add 26.7 parts of ammonium persulfate into the reaction kettle at one time. 100 parts of acrylic acid, 33.3 parts of sodium methacrylate, 16.7 parts of sodium α-olefin sulfonate, 3.3 parts of n-octanol and other aqueous solutions are added dropwise, and the dripping is completed within 1 to 4 hours. After dropping, stir at room temperature for 1 hour. Finally, a certain amount of liquid caustic soda was added into the reaction kettle to make the pH 5-7, and a new polycarboxylate wet-mix mortar plasticizer with stable physical state was obtained, and the recorded sample was P-1.

Embodiment 2

[0018] The preparation of embodiment 2 polycarboxylic acid type wet-mix mortar plasticizer

[0019] First, 833.3 parts of acrylamide and 8000 parts of deionized water are added to the reactor in a certain proportion. The temperature was then controlled at 25°C with constant stirring. Add 25 parts of ammonium persulfate to the reaction kettle at one time. 100 parts of acrylic acid, 66.7 parts of sodium methacrylate, 26.7 parts of sodium α-olefin sulfonate, 6.7 parts of n-octanol and other aqueous solutions were added dropwise, and the dripping was completed within 1 to 4 hours. After dropping, stir at room temperature for 1 hour. Finally, a certain amount of liquid caustic soda was added to the reaction kettle to make the pH 5-7, and a new polycarboxylate wet-mix mortar plasticizer with stable physical state was obtained, and the recorded sample was P-2.

Embodiment 3

[0020] The preparation of embodiment 3 polycarboxylic acid type wet-mix mortar plasticizer

[0021] First, 500 parts of acrylamide and 12,000 parts of deionized water are added to the reactor in a certain proportion. The temperature was then controlled at 20°C with constant stirring. Add 33.3 parts of sodium persulfate into the reaction kettle at one time. Add dropwise the aqueous solution of 100 parts of methacrylic acid, 50 parts of sodium methacrylate, 20 parts of sodium α-olefin sulfonate, 6.7 parts of n-octanol, 13.3 parts of vitamin C, etc., and control the dripping in 1 to 4 hours. After dropping, stir at room temperature for 1 hour. Finally, a certain amount of liquid caustic soda was added into the reaction kettle to make the pH 5-7, and a new polycarboxylate wet-mix mortar plasticizer with stable physical state was obtained, and the recorded sample was P-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com