Poplar single ply intensifier and its usage in intensifying poplar single ply

A technology of poplar veneer and strengthening agent, which is applied in the direction of humidity control wood, impregnated wood, wood impregnation, etc., can solve the problems of loose structure, low strength, soft poplar material, etc., with simple method, simple proportion, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

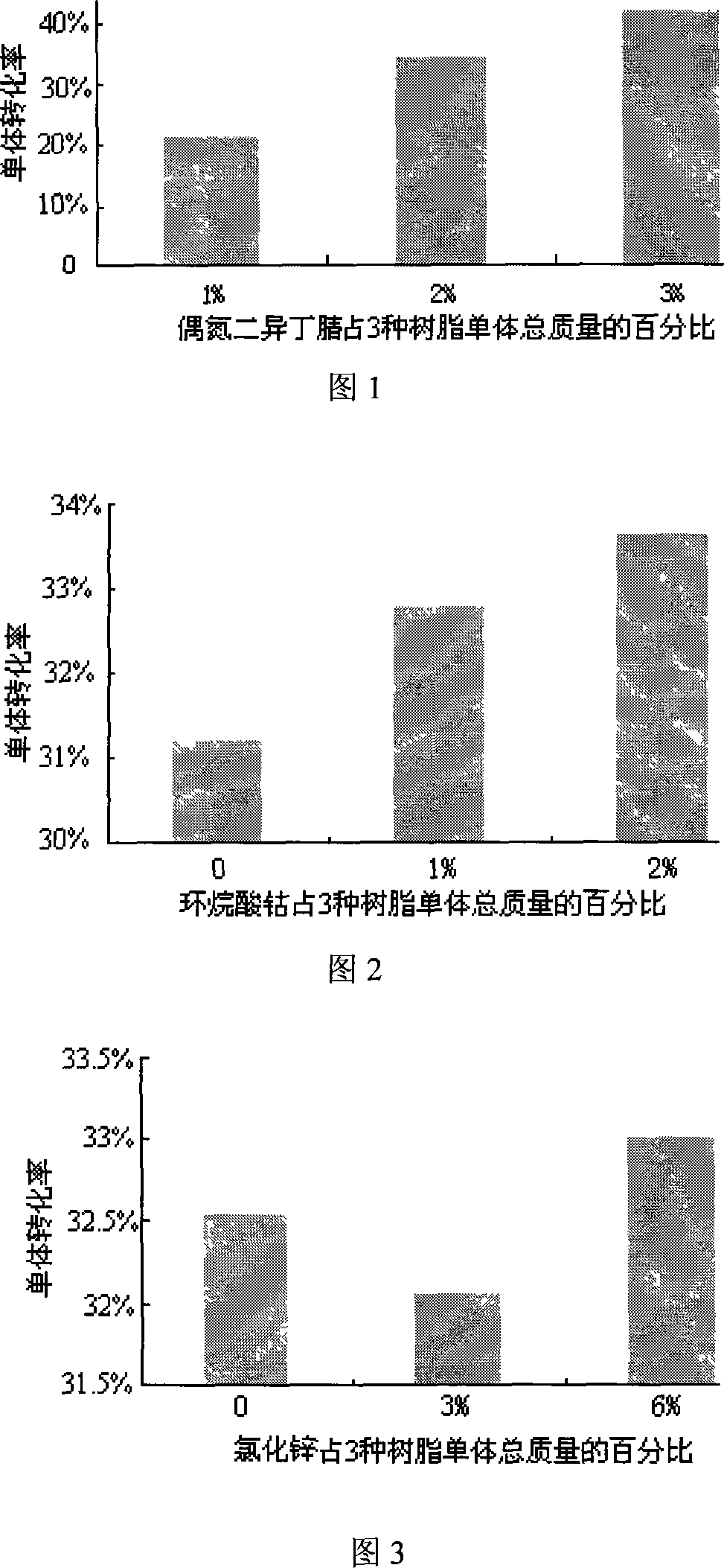

[0007] Specific implementation mode 1: The poplar veneer strengthening agent in this embodiment consists of 24-26 parts of styrene, 48-52 parts of methyl methacrylate, 24-26 parts of vinyl acetate, 2.8-3.2 parts of even It is made of nitrogen diisobutyronitrile, 1.8-2.2 parts of cobalt naphthenate and 5.8-6.2 parts of zinc chloride.

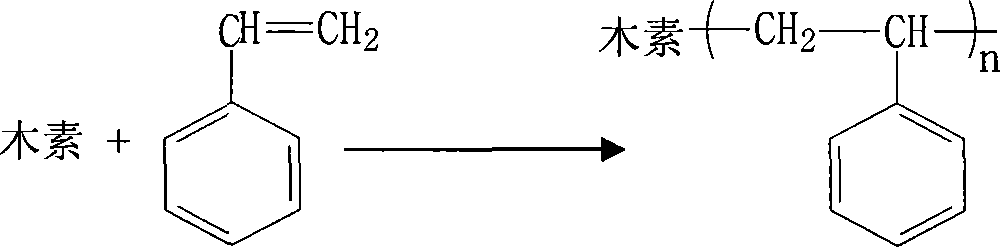

[0008] In this embodiment, azobisisobutyronitrile (AIBN) is used as an initiator. Azobisisobutyronitrile is easily decomposed into a free radical compound, which is violently decomposed in an environment of 80-90°C, and the reaction speed is accelerated. The decomposition reaction is as follows Show: . The decomposition of azobisisobutyronitrile is characterized by almost all first-order reactions, only one free radical is formed, and there is no induced decomposition. In the presence of unsaturated vinyl monomers (styrene, methyl methacrylate and vinyl acetate) Polymerization is initiated under existing conditions, so azobisisobutyronitrile ...

specific Embodiment approach 2

[0014] Specific embodiment two: The difference between this embodiment and specific embodiment one is: the poplar veneer strengthening agent is composed of 25 parts of styrene, 50 parts of methyl methacrylate, 25 parts of vinyl acetate, 3 Parts azobisisobutyronitrile, 2 parts cobalt naphthenate and 6 parts zinc chloride.

specific Embodiment approach 3

[0015] Specific embodiment three: the method for strengthening poplar veneer in this embodiment is carried out according to the following steps: (1) 24~26 parts of styrene, 48~52 parts of methyl methacrylate, 24~26 parts of vinyl acetate, 2.8 ~3.2 parts of azobisisobutyronitrile, 1.8~2.2 parts of cobalt naphthenate and 5.8~6.2 parts of zinc chloride are evenly stirred together to make a poplar veneer strengthening agent; (2) Immerse the poplar veneer in the reinforcement (3) Apply a pressure of 0.38-0.45MPa to the poplar veneer in the pressure tank immersed in the strengthening agent for 60±2min, and then seal it under normal pressure for 2±0.1h; ( 4) Take out the poplar veneer to absorb the strengthening agent on the surface, then wrap it with polyethylene film and let it stand for 36±1h; Heating in medium temperature for 6±0.1h, and then drying in a vacuum oven at 20±0.1°C for 2-3h to obtain strengthened poplar veneer.

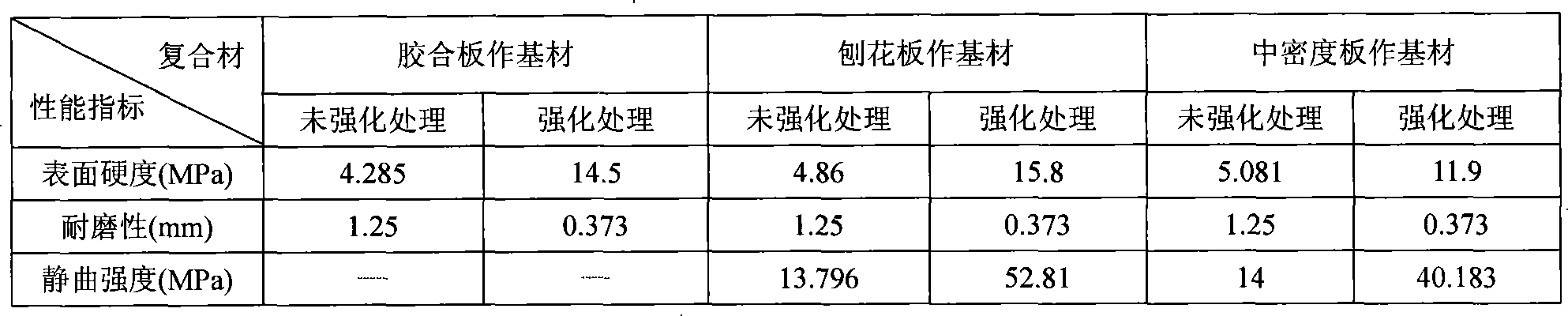

[0016] This embodiment refers to the national standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com