Method for producing sustained-release granular potassium chloride fertilizer

A production method and technology of slow-release granules are applied in the directions of potash fertilizers, inorganic fertilizers, fertilizer mixtures, etc., to achieve the effects of short technological process, low production cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

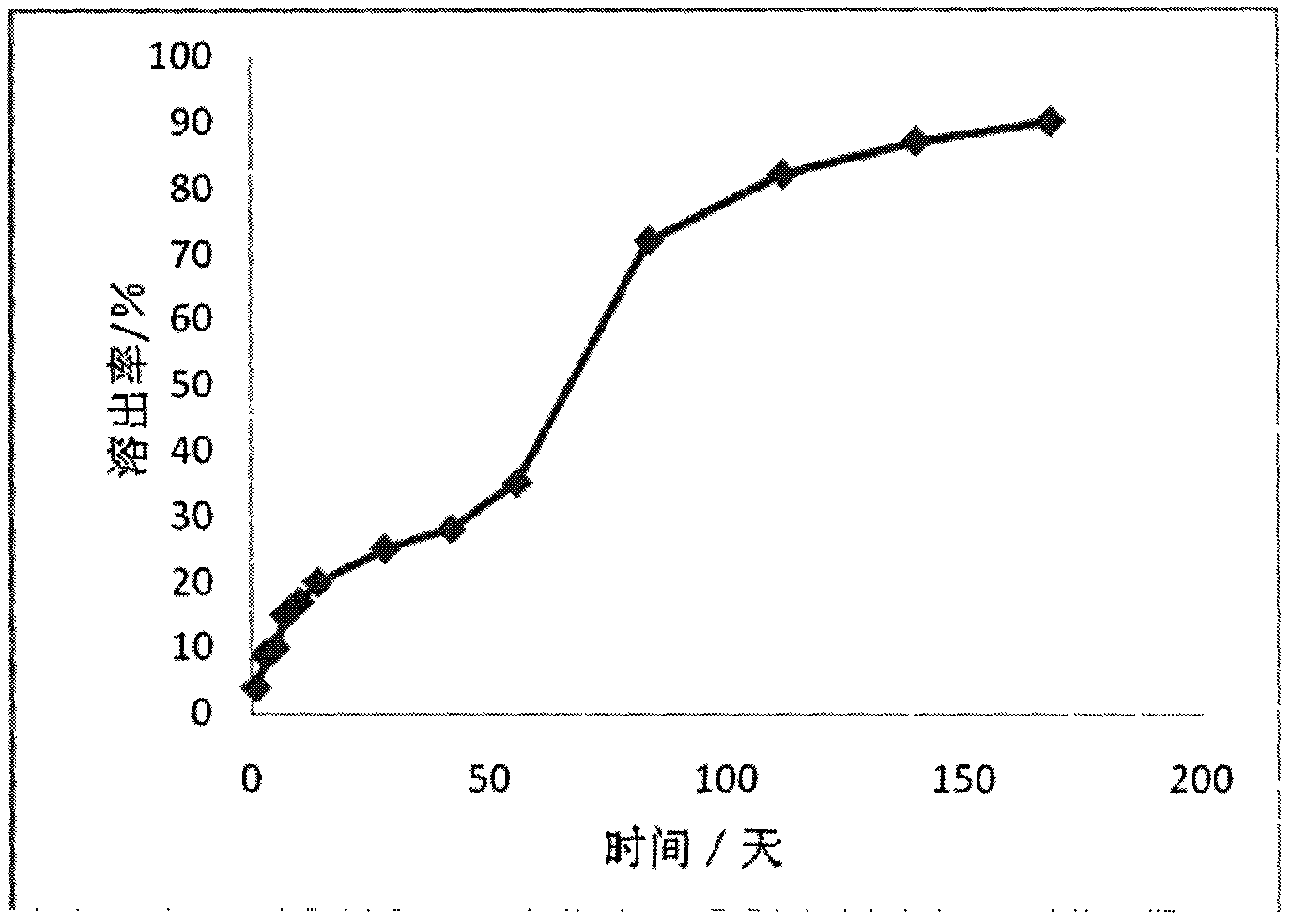

example 1

[0025] Preparation of coating agent: 53 parts (mass) of linseed oil, 9.3 parts (mass) of glycerin, 8.3 parts (mass) of polyether, and 0.18 parts (mass) of calcium naphthenate are added in a high-temperature reactor, and nitrogen protection is carried out. While stirring, heat up to 250°C±2°C, react under heat preservation for 2 hours, stop heating and stirring. Put the reaction materials into the low-temperature reaction kettle immediately, turn on the stirrer of the low-temperature reaction kettle, maintain the temperature of the material at 60°C, pass through nitrogen protection, and add 29 parts (mass) of TDI-80 into the low-temperature reaction kettle at 60-65°C, Addition was complete in about 45 minutes. While adding TDI-80, add 20 parts (mass) of xylene. After TDI was added, 80 parts (mass) of xylene was added into the low-temperature reactor. After stirring and mixing the materials evenly, heat up to 90-93°C, react for 30 minutes and cool down to 50-53°C, add 5 parts ...

example 2

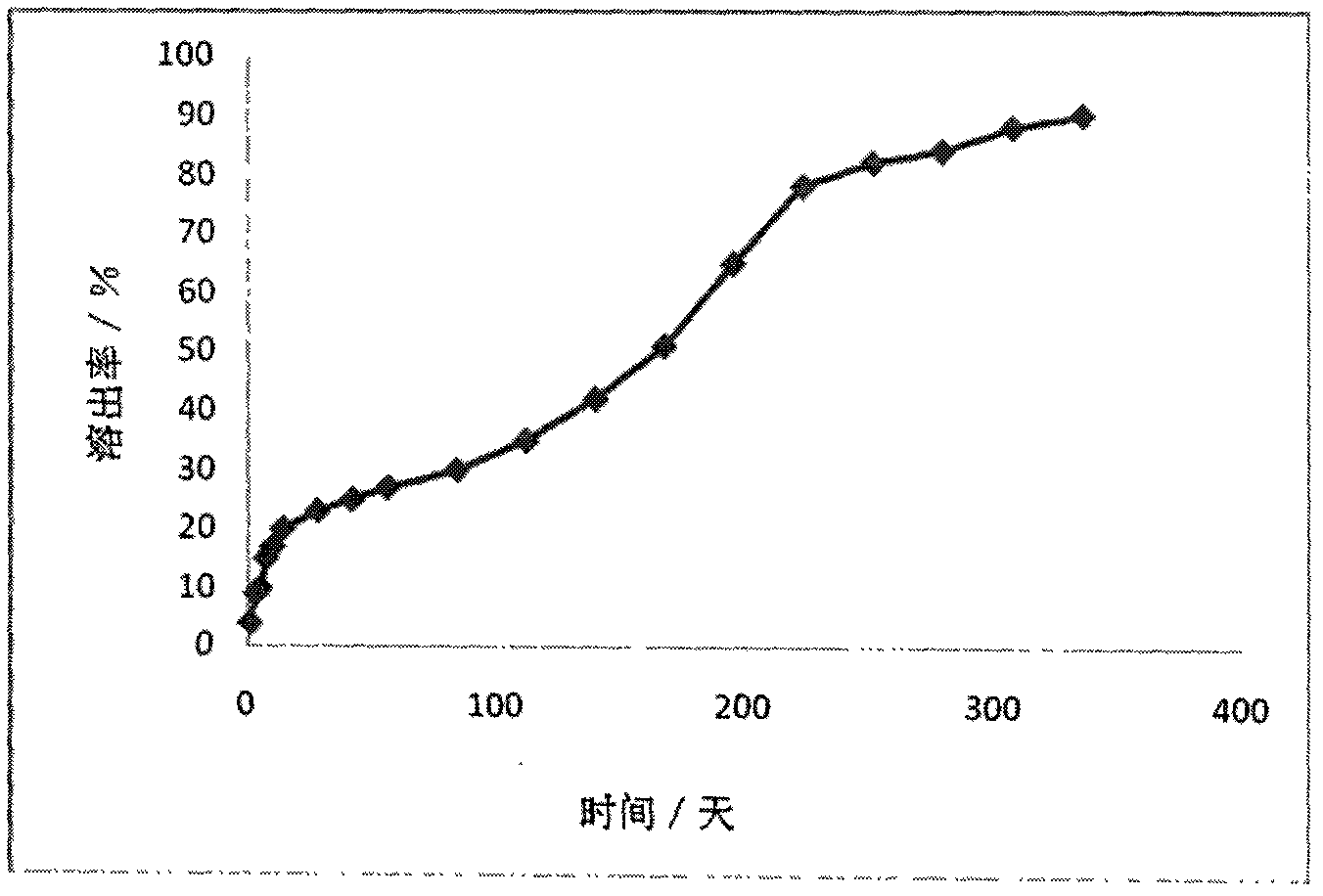

[0029] Preparation of the coating agent: 55 parts (mass) of linseed oil, 9.5 parts (mass) of glycerin, 8.4 parts (mass) of polyether, and 0.2 parts (mass) of calcium naphthenate are added to a high-temperature reactor, and nitrogen protection is carried out. While stirring, heat up to 250°C±2°C, react under heat preservation for 2 hours, stop heating and stirring. Put the reaction materials into the low-temperature reactor immediately, turn on the stirrer of the low-temperature reactor, maintain the temperature of the material at 60°C, pass through nitrogen protection, and add 30 parts (mass) of TDI-80 into the low-temperature reactor at 63°C, about 40 minutes to join. While adding TDI-80, add 20 parts (mass) of xylene. After the TDI-80 was added, 80 parts (mass) of xylene was added to the low-temperature reaction kettle. After stirring and mixing all materials evenly, heat up to 86-90°C, react for 30 minutes and cool down to 54°C, add 5.5 parts (mass) of stabilizer methanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com