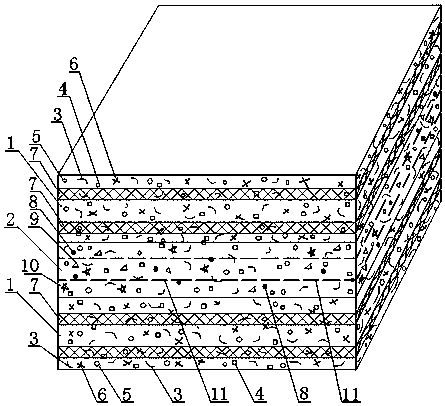

A kind of high-strength antistatic composite material plate and its preparation method

A composite material, anti-static technology, applied in the direction of chemical instruments and methods, lamination, coating, etc., can solve the problems of explosion, high strength and high anti-static at the same time, and achieve a high degree of mechanization and strong designability , the effect of high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of preparation method of high-strength antistatic composite material plate, its preparation process is:

[0039] (1) Weigh 1 part by weight of graphene, add it to 15 parts by weight of dimethylformamide, ultrasonically disperse for 1.5 hours, then add 0.3 parts by weight of triethylenetetramine and 0.3 parts by weight of dicyclohexyl carbonyl Imine, ultrasonic treatment for 15 minutes again, after reacting at 125°C for 45h, adding 4 parts by weight of ethanol, standing for 54h, filtering, washing the obtained precipitate, and vacuum drying at 60°C for 42h to obtain modified graphene;

[0040] (2) Prepare a dilute sulfuric acid solution with a concentration of 15% by mass, immerse all the copper powder in the dilute sulfuric acid solution, ensure that the liquid level of the dilute sulfuric acid exceeds the copper powder by 15cm, sonicate for 45min, then let stand for 36h, then sonicate again for 45min , filter to remove the sulfuric acid solution, t...

Embodiment 2

[0051] Embodiment 2: A kind of preparation method of high-strength antistatic composite material plate, its preparation process is:

[0052] (1) Weigh 1 part by weight of graphene, add it to 10 parts by weight of dimethylformamide, ultrasonically disperse for 1 hour, then add 0.2 part by weight of triethylenetetramine and 0.1 part by weight of dicyclohexylcarbonyl Amine, again sonicated for 10 min, reacted at 120°C for 40h, added 3 parts by weight of ethanol, stood still for 48h, filtered, washed the obtained precipitate, and vacuum dried at 55°C for 36h to obtain modified graphene;

[0053] (2) Prepare a dilute sulfuric acid solution with a concentration of 10% by mass, immerse all the copper powder in the dilute sulfuric acid solution, ensure that the liquid level of the dilute sulfuric acid exceeds the copper powder by 10cm, sonicate for 30min, then let stand for 24h, then sonicate again for 30min , filter to remove the sulfuric acid solution, then rinse the copper powder w...

Embodiment 3

[0064] Embodiment 3: a kind of preparation method of high-strength antistatic composite material plate, its preparation process is:

[0065] (1) Weigh 1 part by weight of graphene, add it to 20 parts by weight of dimethylformamide, ultrasonically disperse it for 2 hours, then add 0.4 part by weight of triethylenetetramine and 0.5 part by weight of dicyclohexylcarbonyl Amine, ultrasonic treatment for 20min again, after reacting at 130°C for 50h, adding 5 parts by weight of ethanol, standing for 60h, filtering, washing the obtained precipitate, and vacuum drying at 65°C for 48h to obtain modified graphene;

[0066] (2) Prepare a dilute sulfuric acid solution with a concentration of 20% by mass, immerse all the copper powder in the dilute sulfuric acid solution, ensure that the liquid level of the dilute sulfuric acid exceeds the copper powder by 20cm, sonicate for 60min, then let it stand for 48h, then sonicate again for 60min , filter to remove the sulfuric acid solution, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com