Glass fibre/vinyl ester resin composite material with interface modification by nanometer SiO2 and preparation method thereof

A vinyl ester resin and glass fiber technology, which is applied in the field of nano-SiO2 interface modified glass fiber/vinyl ester resin composite material and its preparation, can solve the problems of poor strength and impact resistance of composite materials, and improve mechanical properties. performance, improve performance, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

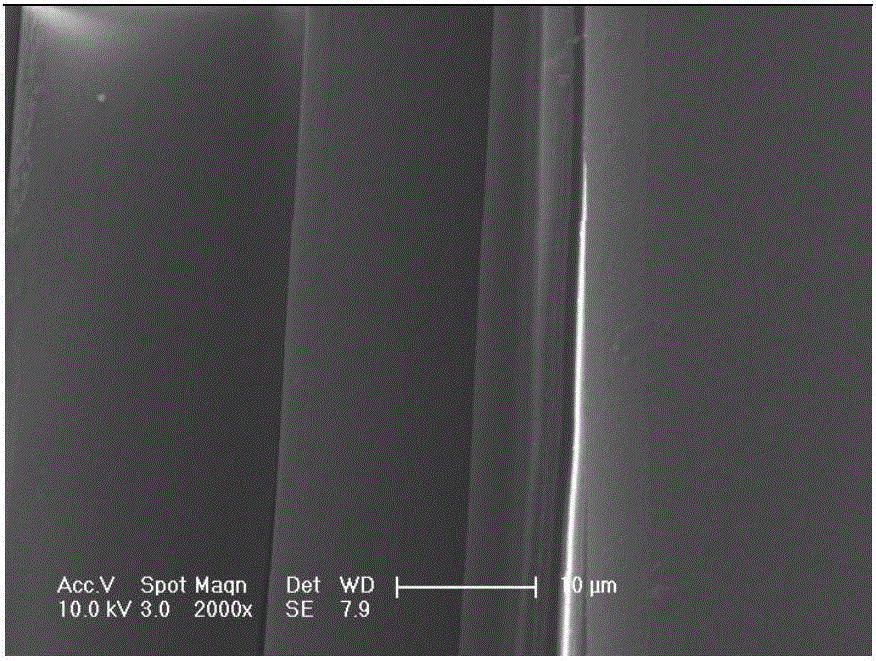

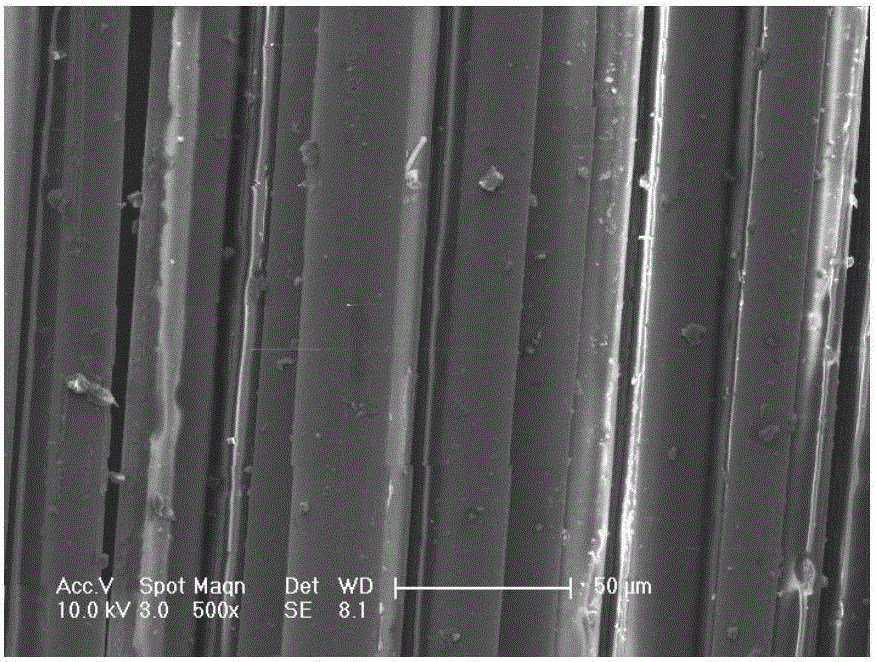

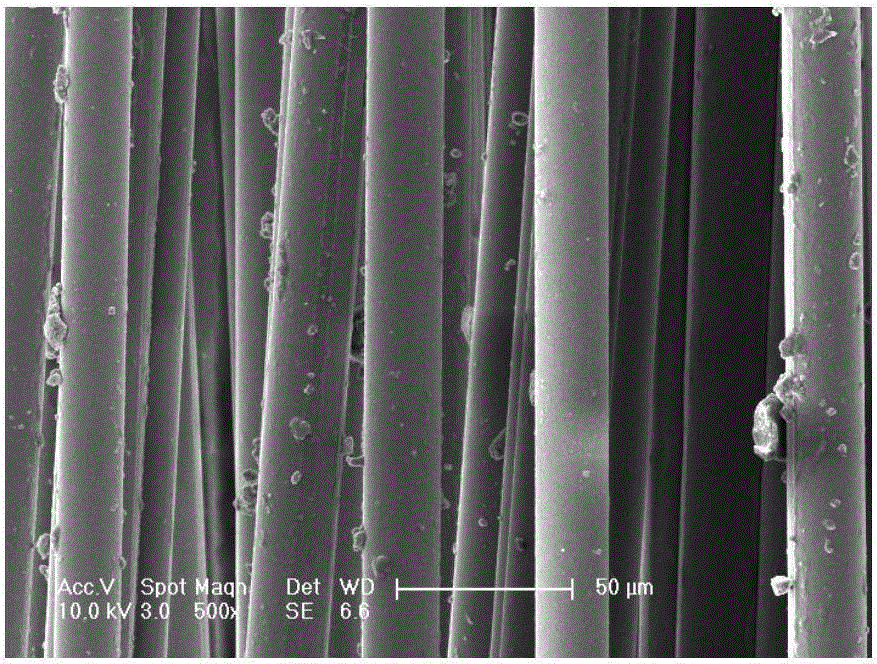

[0039] 1) 0.20g nano-SiO 2 Add to 10mL of ethanol, then add 0.01g of KH-550, ultrasonic vibration for 20min to form a stable suspension.

[0040] 2) Soak 200g of glass fiber in 25mL of ethanol to clean the surface, spread it on the workbench after drying, spray nano-SiO 2 The alcohol suspension was sprayed onto the prepared glass fiber five times, and placed at room temperature until the ethanol was fully volatilized, and then cut according to the sample size for use.

[0041] 3) Take 200g of vinyl ester resin (A407-901) epoxy resin, add 3.5g of methyl ethyl ketone peroxide, 2.5g of N,N-dimethylformamide and 3.5g of cobalt naphthenate, and vacuumize and stir for 0.5h .

[0042] 4) with the nano-SiO that step 2) obtains 2 The modified glass fiber is put into the mold, and then the vinyl ester resin mixture prepared in step 3) is gradually added into the mold, and then cured at 120°C for one hour to obtain nano-SiO 2 Interface modified glass fiber / vinyl ester resin composite...

Embodiment 2

[0046] 1) 0.25g nano-SiO 2 Added to 10mL of ethanol, then added 0.01g of A-143, and ultrasonically oscillated for 20min to form a stable suspension.

[0047] 2) Soak 250g of glass fiber in 25mL of ethanol to clean the surface, spread it on the workbench after drying, spray nano-SiO 2 The alcohol suspension was sprayed onto the prepared glass fiber five times, and placed at room temperature until the ethanol was fully volatilized, and then cut according to the sample size for use.

[0048] 3) Take 300g of vinyl ester resin (A407-901) epoxy resin, add 9.0g of methyl ethyl ketone peroxide, 7.0g of N,N-dimethylformamide and 7.0g of cobalt naphthenate, and vacuumize and stir for 0.5h .

[0049] 4) with the nano-SiO that step 2) obtains 2 The modified glass fiber is put into the mold, and then the vinyl ester resin mixture prepared in step 3) is gradually added to the mold, and then cured at 100°C for one hour to obtain nano-SiO 2 Interface modified glass fiber / vinyl ester resin...

Embodiment 3

[0053] 1) 0.50g nano-SiO 2 Added to 10mL of ethanol, then added 0.005g of A-151, and ultrasonically oscillated for 20min to form a stable suspension.

[0054] 2) Soak 100g of glass fiber in 25mL of ethanol to clean the surface, spread it on the workbench after drying, spray nano-SiO 2 The alcohol suspension was sprayed onto the prepared glass fiber five times, and placed at room temperature until the ethanol was fully volatilized, and then cut according to the sample size for use.

[0055] 3) Take 120g of vinyl ester resin (A407-901) epoxy resin, add 3g of methyl ethyl ketone peroxide, 2g of N,N-dimethylformamide and 2g of cobalt naphthenate, and stir under vacuum for 0.5h.

[0056] 4) with the nano-SiO that step 2) obtains 2 The modified glass fiber is put into the mold, and then the vinyl ester resin mixture prepared in step 3) is gradually added to the mold, and then cured at 140°C for one hour to obtain nano-SiO 2 Interface modified glass fiber / vinyl ester resin composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com