Preparation method of sound-absorption honeycomb with embedded micro-perforated sound-eliminating separating plates

A technology of micro-perforation and honeycomb, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc. It can solve the problems of the decline of the mechanical properties of the acoustic lining and the increase of its own weight, so as to maintain the mechanical properties and reduce its own weight. , The effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

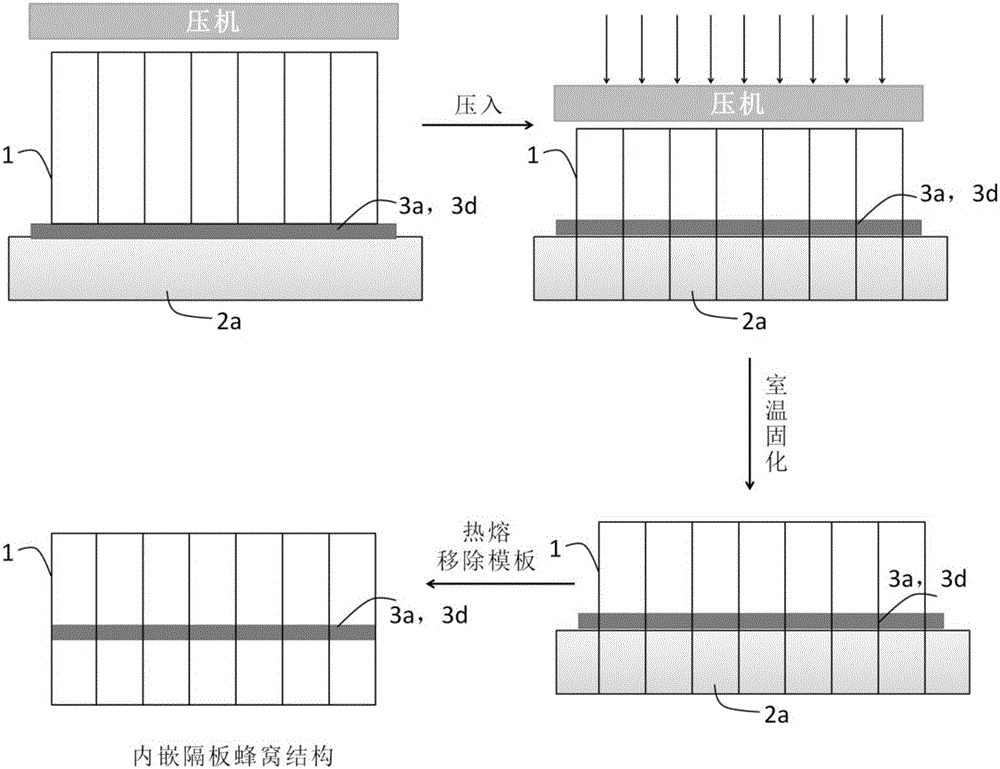

[0030] A design and preparation technology for the preparation of a sound-absorbing honeycomb with an embedded micro-perforated sound-absorbing partition, characterized in that the design and preparation steps ( figure 1 )as follows:

[0031] (1) Select aramid paper honeycomb, glass cloth honeycomb, aluminum honeycomb or plant fiber honeycomb core with cell side length of 2.0mm-8.0mm;

[0032] (2) Select paraffin as the template material, and the brand on the paraffin layer is SY-37 low-temperature curing resin (product of Beijing Aeronautical Materials Research Institute), and the temperature is lowered below the freezing point of the paraffin;

[0033] (3) Use paraffin wax as the template material for the lower layer, and the upper layer is covered with low-temperature curing resin SY-37, and press it into the inner cavity of the honeycomb at the same time by using a press. The depth is 10%-90% of the honeycomb depth;

[0034] (4) According to the requirements of the resin...

Embodiment 2

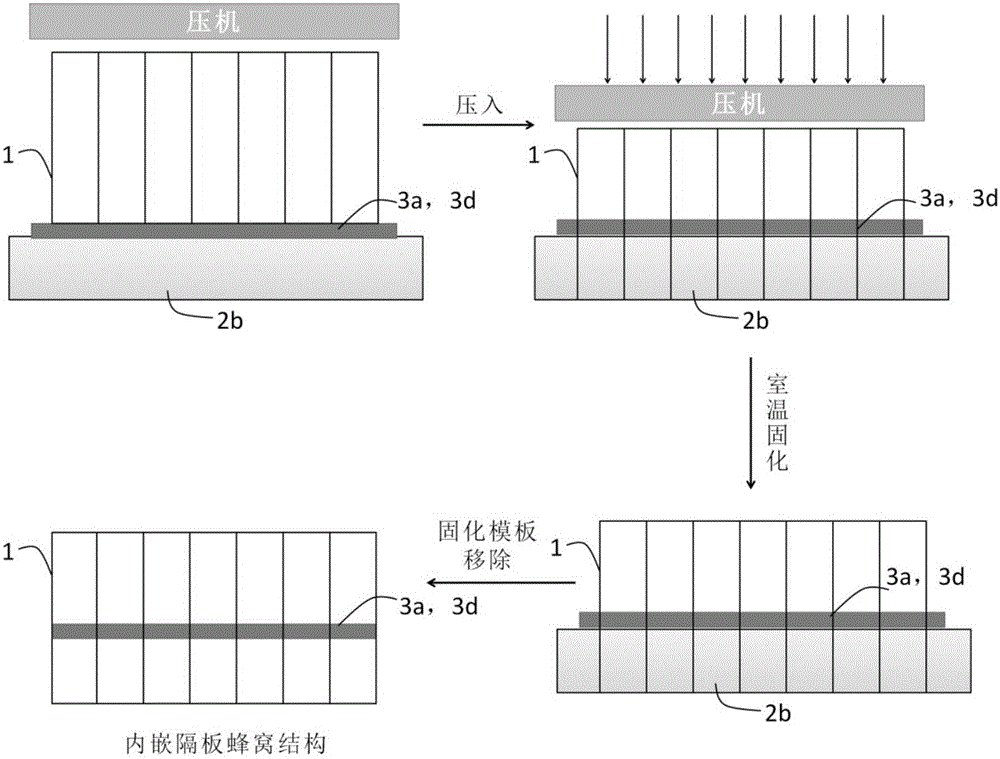

[0038] Similar to Example 1, using paraffin as a template material, a design and preparation technology for the preparation of a sound-absorbing honeycomb with an embedded micro-perforated sound-absorbing partition, is characterized in that the design and preparation steps ( figure 1 )as follows:

[0039] (1) The main difference between it and Example 1 is that the unsaturated polyester with grade 240 (produced by Ashland) or grade 8175 (DSM) is selected as the embedded sound-absorbing partition material;

[0040] (2) paraffin is selected as the template material, and the unsaturated polyester of the above-mentioned brand is spread on the paraffin, and the temperature is down to below the paraffin freezing point;

[0041] (3) Use paraffin wax as the template material for the lower layer, and the upper layer is covered with liquid unsaturated polyester, and press it into the honeycomb cavity at the same time with a press. The depth of the honeycomb pressed into the resin and th...

Embodiment 3

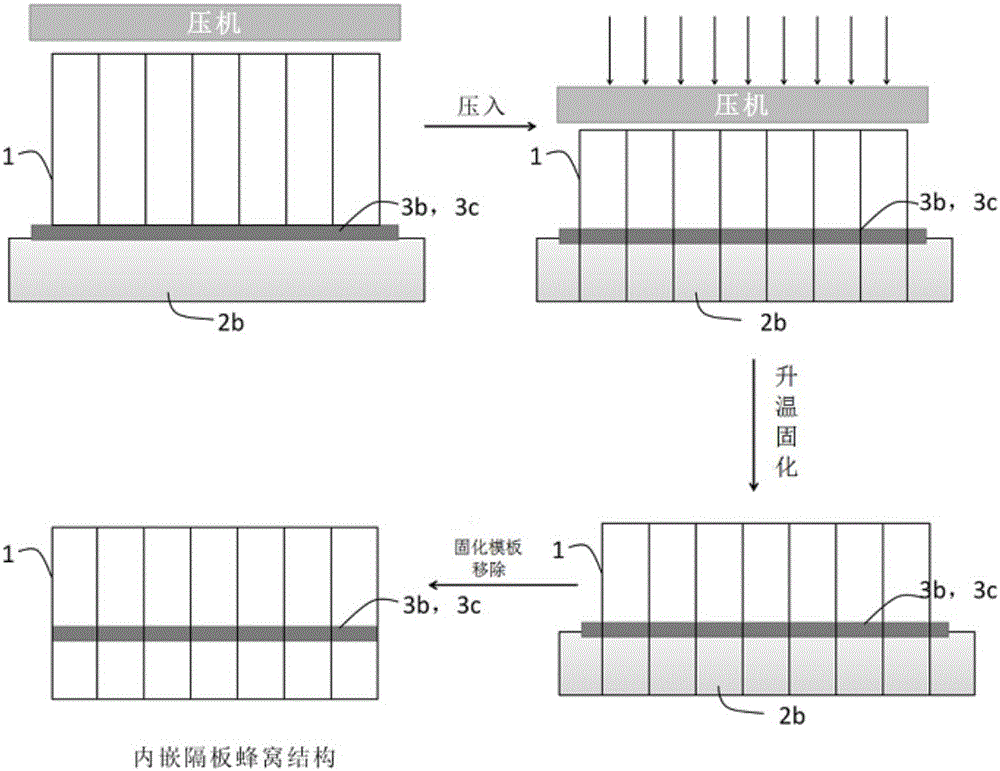

[0046] 1. A design and preparation technology for the preparation of sound-absorbing honeycomb with embedded micro-perforated sound-absorbing partition, characterized in that the design and preparation steps of sound-absorbing honeycomb ( figure 2 )as follows:

[0047] ((1) Choose aramid paper honeycomb, glass cloth honeycomb, aluminum honeycomb or plant fiber honeycomb with cell side length of 2.0mm-8.0mm;

[0048] (2) Select clay or gypsum, and after mixing with water, make a soft clay or gypsum group, as a self-made mold board, the shop grade is SY-37 low-temperature curing resin (product of Beijing Aeronautical Materials Research Institute);

[0049] (3) The lower layer is made of clay or gypsum as a self-made mold board, and the upper layer is covered with low-temperature curing resin SY-37, which is pressed into the honeycomb cavity at the same time by a press. The depth of the honeycomb pressed into the resin and the supporting mold board is determined according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com