Pipeline sludge solidification treatment method

A technology for solidification treatment and sludge, which is used in dewatering/drying/concentrating sludge treatment, solid waste management, sustainable waste treatment, etc. The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

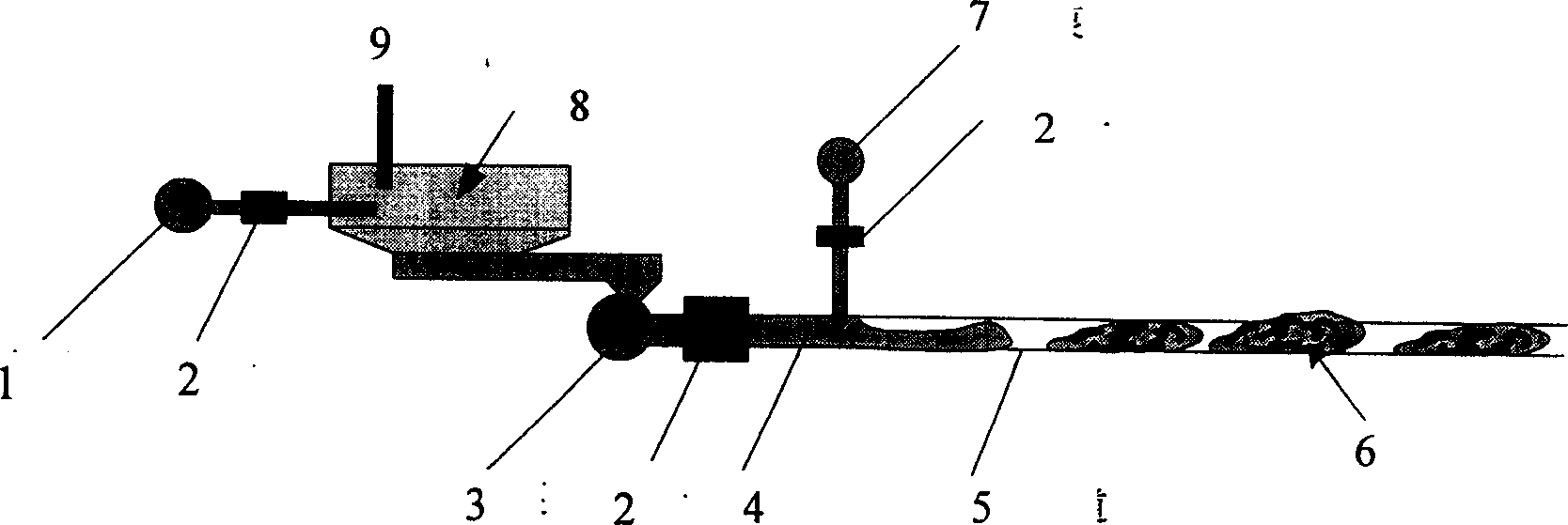

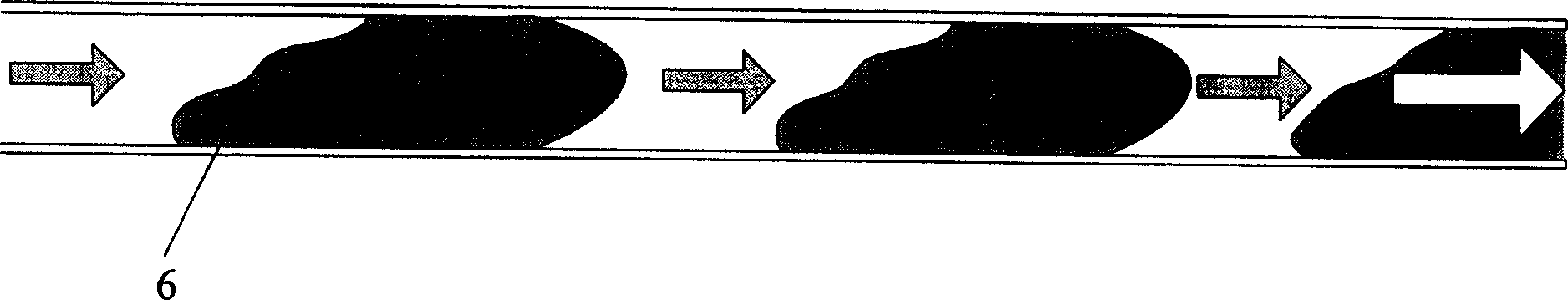

Method used

Image

Examples

Embodiment Construction

[0020] A certain sea area near the Minjiang Estuary in Fujian needs to be filled with land for land reclamation, and it is planned to adopt the method of pipeline silt solidification for land reclamation. The marine silt in this sea area has a water content of 105% and a bulk density of 1.5 tons / m 3 , the project requires the strength of the solidified sludge to reach 200kPa at the age of 90 days.

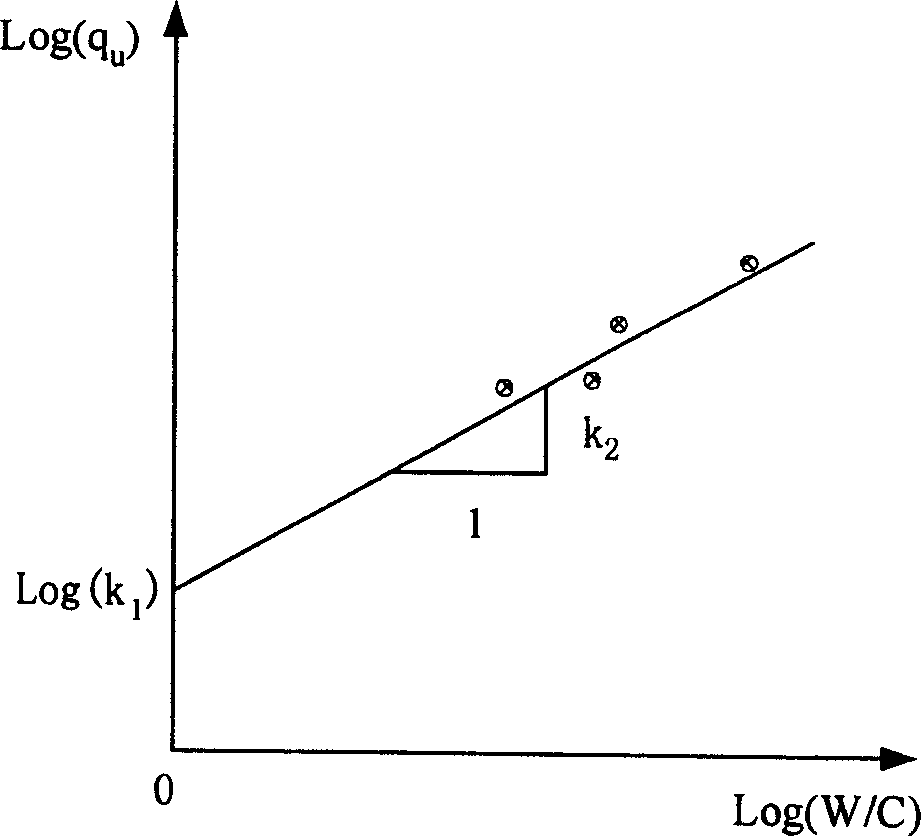

[0021] 1) The unconfined compressive strength, q u The coefficient k in the relational expression with the total water-cement ratio W / C 1 and k 2 are 50 and 0.8 respectively, so it can be deduced that when the design strength requirements are met, the total water-cement ratio W / C is 5.6. It is determined that when the water content of the mixture is 150%, its fluidity is very good, so the target water content is 150%. Therefore, the cement to be added per cubic meter of sludge is 1700*1.5 / 2.5 / 5.6=182kg.

[0022] 2) Pass the dredged silt through a 1cm sieve to remove boulders, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com