Squeezing cement plugging technical skill for thick oil absorption well

A process technology, cement extrusion technology, applied in sealing/packing, wellbore/well components, earthwork drilling and production, etc., to achieve the effects of reducing operational risks, saving costs, and novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

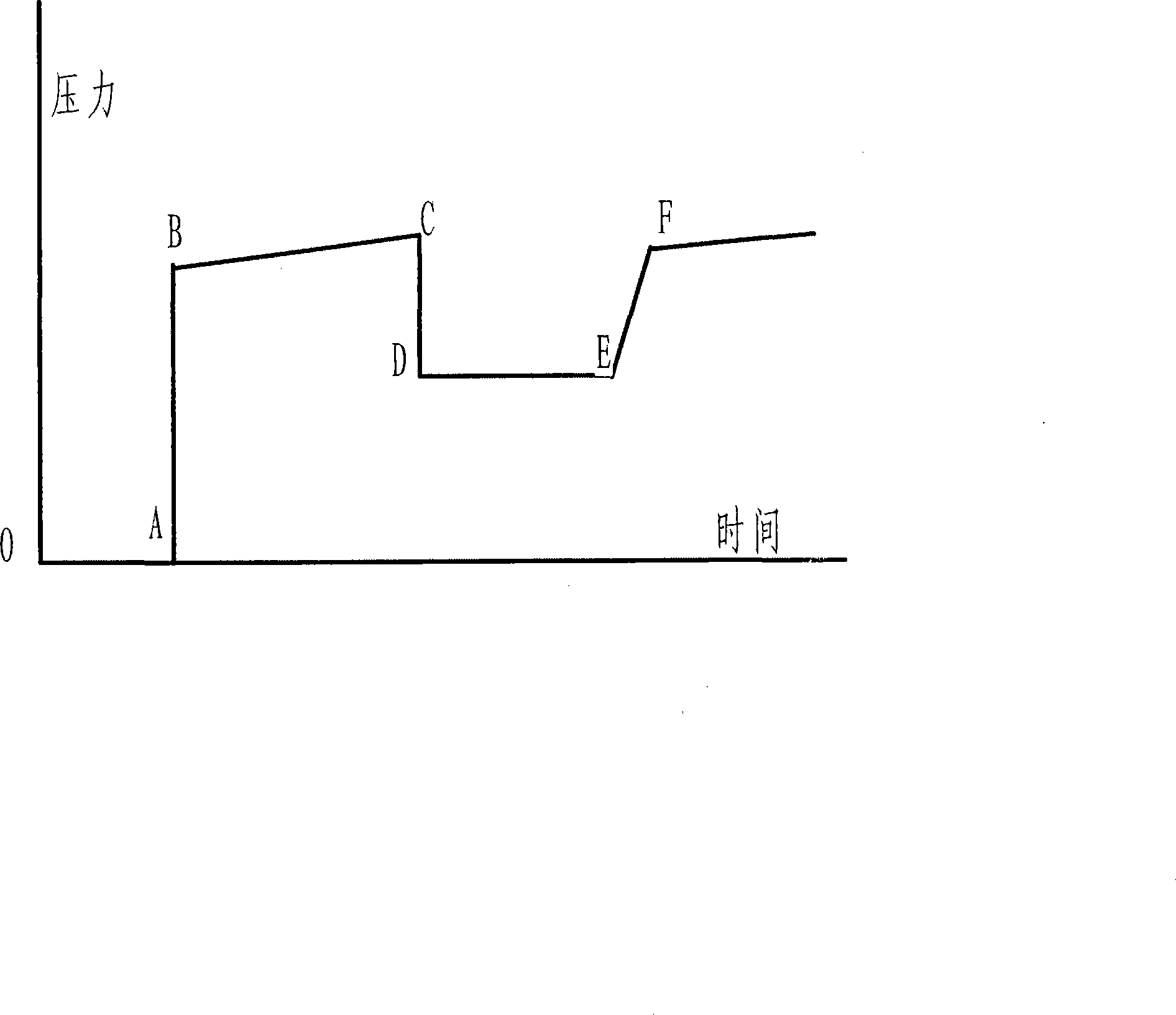

[0027] As shown in the figure, during the sealing operation of heavy oil wells, the above-mentioned implementation steps should be followed, and the three methods mentioned above should be used to judge whether the balance fluid has reached the pipe shoe. In the figure, from O to A is the stage of oil well leakage, from B to C is the stage of pressure recovery, from C to E is the stage of the balance fluid entering the cement layer, and EF is the normal extrusion of no balance fluid below the pipe shoe after the balance fluid is stopped. stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com