Multi-functional environment-friendly grinding aid

A grinding aid and multi-functional technology, applied in the field of cement grinding aids, can solve the problems of low safety factor, unsatisfactory effect, corrosion of steel bars, etc.

Inactive Publication Date: 2011-06-29

YANTAI UNIV

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The amount of active mixed materials such as slag and fly ash is relatively large, but some grinding aids have a good effect on clinker grinding, and the effect is not ideal after adding mixed materials

Some grinding aids contain CI-, which has a corrosion effect on steel bars and has a low safety factor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

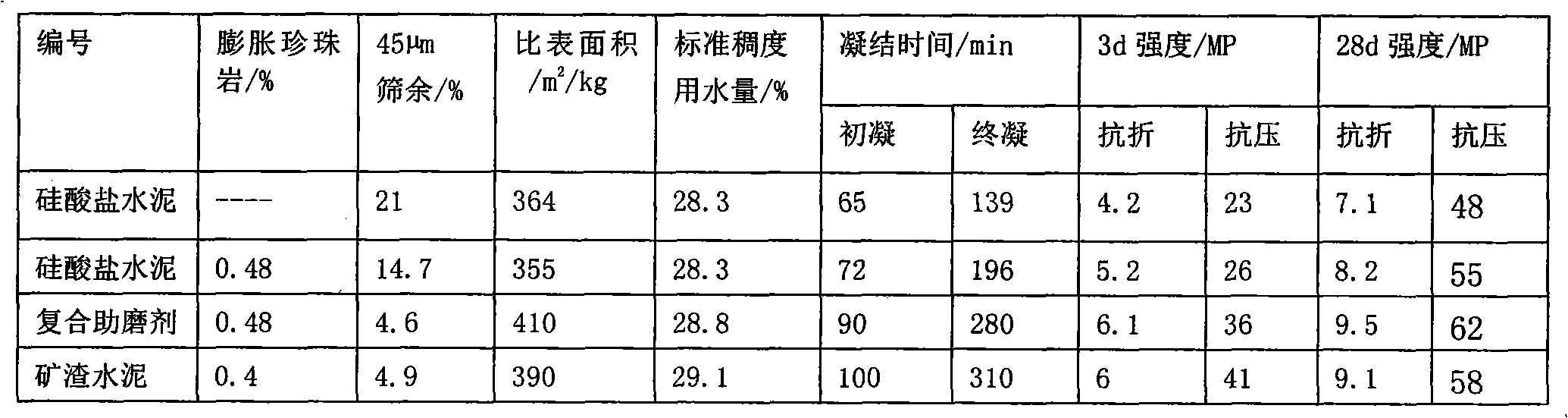

The invention discloses a multi-functional environment-friendly grinding aid, and relates to a cement grinding aid. The invention mainly aims to solve the problems that the energy consumption is high, the grinding efficiency is low, use safety of the grinding aid is low and the like in the cement grinding process. Light and porous expanded perlite is adopted to serve as the grinding aid, can be separately doped or compounded, and has good grinding aiding effect on clinker, slag, flyash and the like. The content of a portland cement grinding aid is 0.2 to 0.5 percent; and the content of a slag cement grinding aid is 0.3 to 0.4 percent. A compound grinding aid comprises 0.48 percent of expanded perlite, 0.001 percent of triethanolamine and 0.003 percent of sodium hexametaphosphate. The multi-functional environment-friendly grinding aid has the advantages that: phenomena of segregation, bleeding and powder enrichment cannot happen in the mortar stirring process; the activity of glass contributes to improving the strength of cement concrete, components harmful to cement and concrete are not contained, and the grinding air is convenient to use, low in price, safe, environment-friendly, high-efficiency and high in applicability; the fine powder content is effectively increased, and the strength of cement cured for 28 days is improved; and the aims of increasing yield, saving energy and reducing consumption are fulfilled.

Description

Multifunctional environmental protection grinding aid technical field The invention relates to a cement grinding aid. Background technique In the cement industry, the energy consumption of the grinding process is very high, and the electricity consumption accounts for about 60-70% of the total electricity consumption of cement production. Grinding aids have multifunctional functions such as increasing mill output, reducing unit energy consumption, increasing fine powder content, and improving cement quality. The amount of active admixtures such as slag and fly ash is relatively large, but some grinding aids have a good effect on clinker grinding, and the effect is not ideal after adding admixtures. Some grinding aids contain CI-, which has a corrosive effect on steel bars and has a low safety factor. Contents of the invention The purpose of the present invention is to use light, porous and highly absorbent expanded perlite as a grinding aid. The main component of exp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B22/06C04B24/12C04B103/52

CPCC04B40/0039

Inventor 王波

Owner YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com