Cement additive for curing organic waste and application of cement additive

A cement additive and organic waste technology, which is applied in the field of waste treatment, can solve the problems such as the inability to solidify the waste process, the organic matter fleeing to the upper layer of the cement slurry, and the poor strength of the solidified body, so as to enhance the performance of the solidified body and enhance the hydration reaction degree, the effect of reducing the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh each component according to the following mass percentage: 10% coagulant calcium formate, 10% oil-absorbing particles, 15% microsilica, 15% activated carbon, 18% wood fiber, 15% fly ash, 17% crack-resistant fibers. The weighed components are pulverized and mixed evenly to obtain the cement additive. In this embodiment, the oil-absorbing material is a superhydrophobic and superoleophilic oil-absorbing granular material, which is a commercially available product.

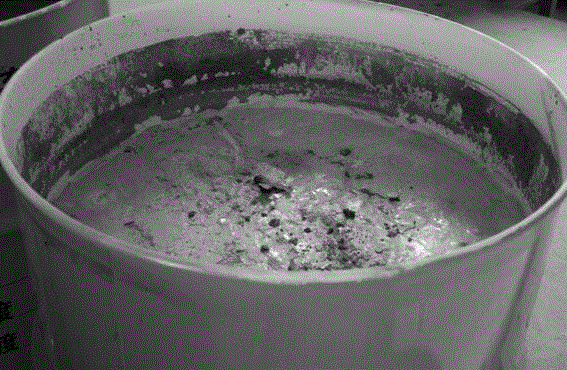

[0047]The above cement additives are added to conventional Portland cement, and 2.5 parts (weight) of cement additives are added to 100 parts (weight) of cement. The mixture of the above cement additives and Portland cement is used to solidify the radioactive oil-water mixture (in the radioactive oil-water mixture, the content of various oils and other organic substances is about 20-30%, and the rest is water).

[0048] After curing, the 28d compressive strength of the cement solidified body is 12.2MPa,...

Embodiment 2

[0054] Weigh each component according to the following mass percentage: 15% coagulant calcium formate, 15% oil-absorbing particles, 10% microsilica, 10% activated carbon, 15% wood fiber, 20% fly ash, 15% crack-resistant fibers. The weighed components are pulverized and mixed evenly to obtain the cement additive. In this embodiment, the oil-absorbing material is a super-hydrophobic and super-oleophilic mesh material, which is a commercially available product.

[0055] The above cement additives are added to conventional Portland cement, and 8.5 parts of cement additives are added to 100 parts (by weight) of Portland cement to obtain the first reactant. Using the first reactant of this embodiment, the radioactive oil-water emulsion (in the radioactive oil-water emulsion, the oil-water ratio is emulsified to form an emulsion) is subjected to cement curing treatment.

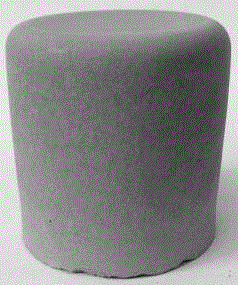

[0056] The prepared cement solidified body as image 3 shown. After curing, the surface of the cement solidif...

Embodiment 3

[0058] Weigh each component according to the following mass percentage: 15% coagulant calcium formate, 5% oil-absorbing particles, 17% microsilica, 18% activated carbon, 15% wood fiber, 14% fly ash, 16% crack-resistant fibers. The weighed components are pulverized and mixed evenly to obtain the cement additive.

[0059] The above cement additives are added to conventional Portland cement, and 2 parts of cement additives are added to 100 parts (by weight) of Portland cement. The cement solidification treatment is carried out on the flocculation sediment of the electroplating waste liquid by using the mixture of the above cement additive and Portland cement.

[0060] The prepared cement solidified body as Figure 4 shown. After measurement, the strength of the cement solidified body obtained after curing in this embodiment is 10.2MPa, and the 42d ion leaching rate is less than 1×10 -5 cm / d. At the same time, the surface of the solidified body prepared in this embodiment is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com