A method for high-temperature solidification of lead-containing sludge

A high-temperature solidification and sludge technology, applied in chemical instruments and methods, sludge treatment, fixed/solidified sludge treatment, etc., can solve problems such as the difficulty of solidification of lead-containing sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

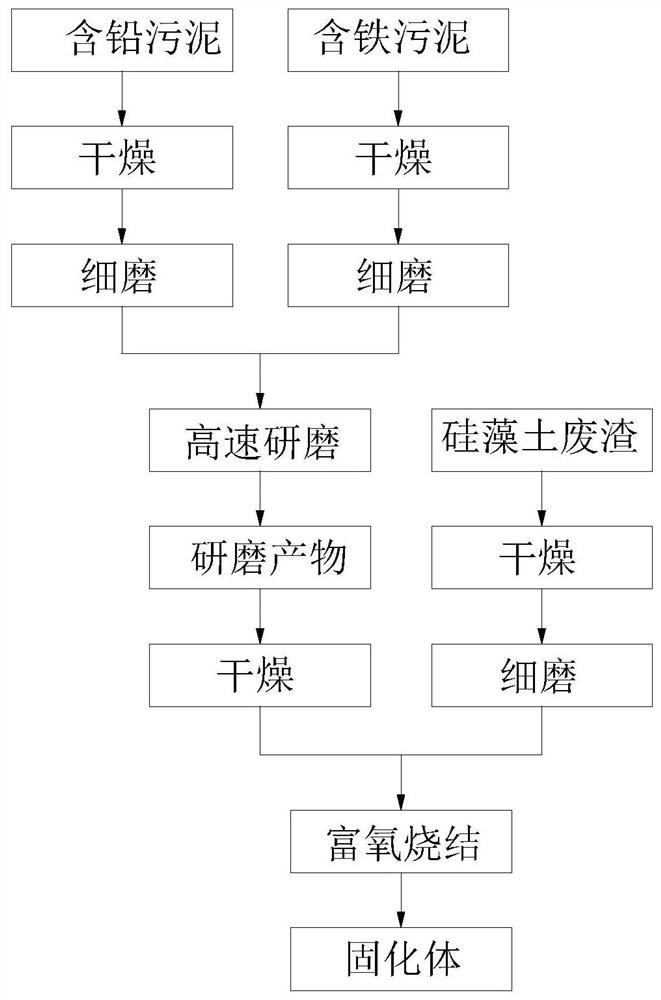

[0031] In this embodiment, lead-containing sludge is treated as the treatment object, and waste disposal is carried out through dual solidification treatment of mechanochemical reaction and high-temperature solidification in an oxygen-enriched atmosphere to strengthen the solidification effect of lead. Such as figure 1 As shown, the specific method is as follows:

[0032] Dry lead-containing sludge, iron-containing sludge and diatomite waste residue to reduce the moisture content of lead-containing sludge, iron-containing sludge and diatomite waste residue from 72%, 70% and 42% to 10% respectively Below; and use a ball mill to grind the dried lead-containing sludge, iron-containing sludge and diatomite waste residue to -38μm.

[0033] A portion of fine-grained lead-containing sludge and iron-containing sludge were uniformly mixed in a mass percentage of 10%:90% on a dry basis, and the mixed material was added to a vertical planetary ball mill for grinding for 5 hours at a spe...

Embodiment 2

[0041] In this embodiment, lead-containing sludge is treated as the treatment object, and waste disposal is carried out through dual solidification treatment of mechanochemical reaction and high-temperature solidification in an oxygen-enriched atmosphere to strengthen the solidification effect of lead. The specific method is as follows:

[0042] Dry lead-containing sludge, iron-containing sludge and diatomite waste residue to reduce the moisture content of lead-containing sludge, iron-containing sludge and diatomite waste residue from 72%, 70% and 42% to 10% respectively Below; and use a ball mill to grind the dried lead-containing sludge, iron-containing sludge and diatomite waste residue to -38 μm; the fine-grained lead-containing sludge and iron-containing sludge are mixed at a dry basis mass percentage of 19%:81% uniform, and the mixed material was added to a vertical planetary ball mill for grinding for 5.5 hours at a speed of 620 rpm. Dry the obtained fine-grained grind...

Embodiment 3

[0045] In this embodiment, lead-containing sludge is treated as the treatment object, and waste disposal is carried out through dual solidification treatment of mechanochemical reaction and high-temperature solidification in an oxygen-enriched atmosphere to strengthen the solidification effect of lead. The specific method is as follows:

[0046] Dry lead-containing sludge, iron-containing sludge and diatomite waste residue to reduce the moisture content of lead-containing sludge, iron-containing sludge and diatomite waste residue from 72%, 70% and 42% to 10% respectively Below; and use a ball mill to grind the dried lead-containing sludge, iron-containing sludge and diatomite waste residue to -38 μm; the fine-grained lead-containing sludge and iron-containing sludge are mixed at a dry basis mass percentage of 22%:78% uniform, and the mixed material was added to a vertical planetary ball mill for grinding for 7 hours at a speed of 550 rpm. Dry the obtained fine-grained grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com