A method for making waterproof magnesium oxychloride refractory bricks by utilizing domestic waste incineration fly ash

A technology of domestic waste incineration and magnesium oxychloride bricks, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of loss of strength, poor water resistance, and limited use range, etc., to achieve water resistance, Simple equipment and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1, utilizing domestic garbage to incinerate fly ash to make waterproof magnesium oxychloride refractory brick

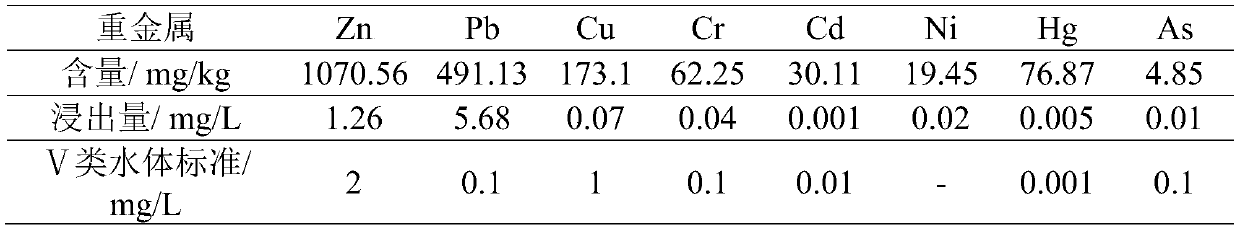

[0061] The fly ash samples came from a waste incineration plant in Daxing District, Beijing. The content and leaching amount of heavy metals in the samples are shown in Table 1. For the leaching method, refer to the Horizontal Oscillation Method for Toxic Leaching of Solid Wastes (HJ557-2010), and for the limit standard, refer to the standard for Class V water bodies in the Environmental Quality Standards for Surface Water (GB3838-2002). It can be seen from Table 1 that the leaching amount of Pb seriously exceeds the standard.

[0062] Table 1 Content and leaching amount of heavy metals in fly ash of a waste incineration plant in Daxing, Beijing

[0063]

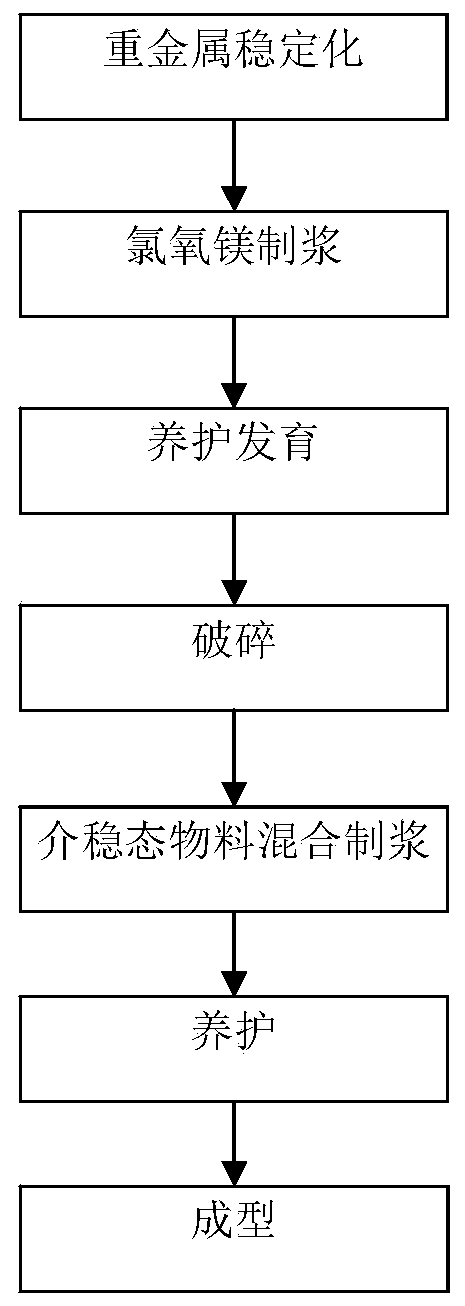

[0064] according to figure 1 The flow chart shown uses domestic waste incineration fly ash to make waterproof magnesium oxychloride refractory bricks. The specific steps are as follows:

[0...

Embodiment 2

[0080] Embodiment 2, utilizing domestic garbage to incinerate fly ash to make waterproof magnesium oxychloride refractory brick

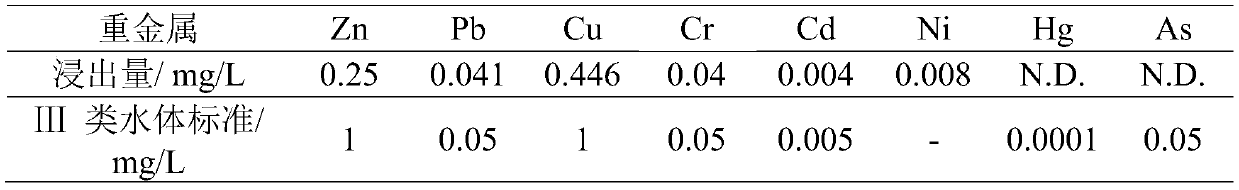

[0081] The fly ash samples came from a waste incineration plant in Xingtai City, Hebei Province. The content and leaching amount of heavy metals in the samples are shown in Table 3. For the leaching method, refer to the Horizontal Oscillation Method for Toxic Leaching of Solid Wastes (HJ557-2010), and for the limit standard, refer to the standard for Class V water bodies in the Environmental Quality Standards for Surface Water (GB3838-2002). It can be seen from Table 3 that the leached amounts of Pb and Zn seriously exceed the standard.

[0082] Table 3 Heavy metal content and leaching amount in fly ash of a waste incineration plant in Xingtai, Hebei

[0083]

[0084] according to figure 1 The flow chart shown uses domestic waste incineration fly ash to make waterproof magnesium oxychloride refractory bricks. The specific steps are as follows: ...

Embodiment 3

[0100] Embodiment 3, making waterproof magnesium oxychloride refractory bricks by utilizing domestic waste incineration fly ash

[0101] The fly ash samples came from a waste incineration plant in Linqu, Shandong. The content and leaching amount of heavy metals in the samples are shown in Table 5. For the leaching method, refer to the Horizontal Oscillation Method for Toxic Leaching of Solid Wastes (HJ557-2010), and for the limit standard, refer to the standard for Class V water bodies in the Environmental Quality Standards for Surface Water (GB3838-2002). It can be seen from Table 5 that the leaching amount of Pb and Cr exceeds the standard.

[0102] Table 5 Heavy metal content and leaching amount in fly ash of a waste incineration plant in Linqu, Shandong

[0103]

[0104] according to figure 1 The flow chart shown uses domestic waste incineration fly ash to make waterproof magnesium oxychloride refractory bricks. The specific steps are as follows:

[0105] (1) Stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com