High-salt high-alkali low and intermediate level radioactive waste solution cement solidification formula

A cement solidification, high alkali technology, applied in the field of radioactive waste liquid solidification treatment, can solve the problems of less solidified formula, less stay, less engineering application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

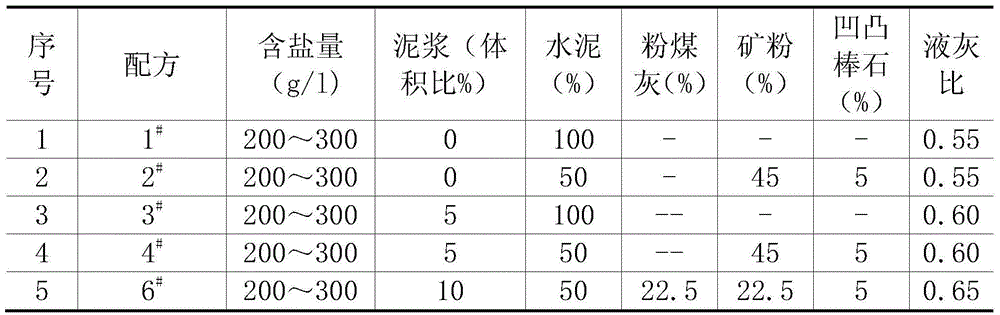

[0017] In this embodiment, ordinary Portland cement P.O42.5R is used as the main inorganic gel solidification base material, and additives such as fly ash, attapulgite, ore powder and the like to change the adsorption performance of cement to nuclides can also be added. After these materials are mixed with waste in proportion, the mortar formed will be cured for a period of time to form a cement solidified body. See the table below for specific ratios:

[0018]

[0019] Cold test sequence: prepare 200g / L, 250g / L, 300g / L simulated liquid and simulated mud according to real waste liquid and α mud, add cement and additives (fly ash, mineral powder, attapulgite Stone) uniformly mixed according to the ratio in Table 1 and added to the stirring pot, and mixed and stirred for 10 minutes.

[0020] Thermal test sequence: take the real waste liquid and medium-release α mud and mix them in the ratio shown in Table 1, then add them to the stirring pot, and mix the cement and additives...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com