Autoclaved sand-lime brick and preparation method thereof

A technology of autoclaved lime-sand bricks and fly ash, which is applied in the field of building materials and can solve the problems of difficult disposal of industrial solid waste, no expansion, and little expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

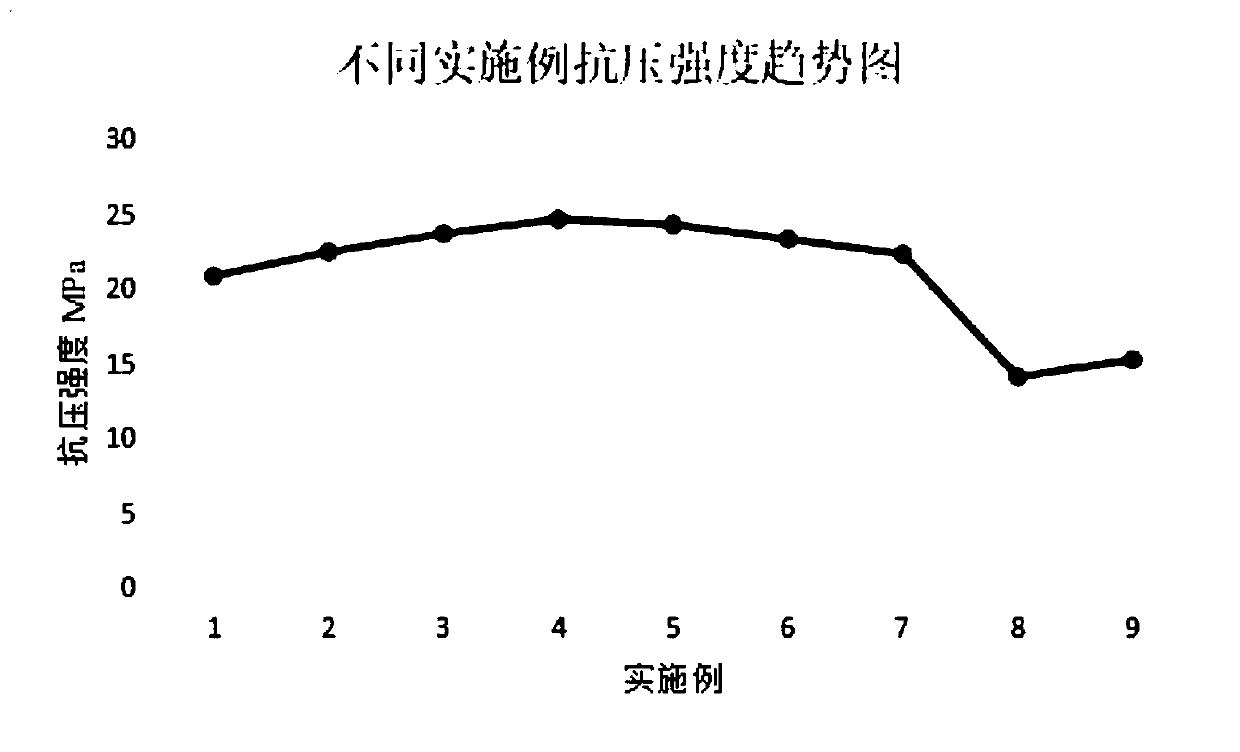

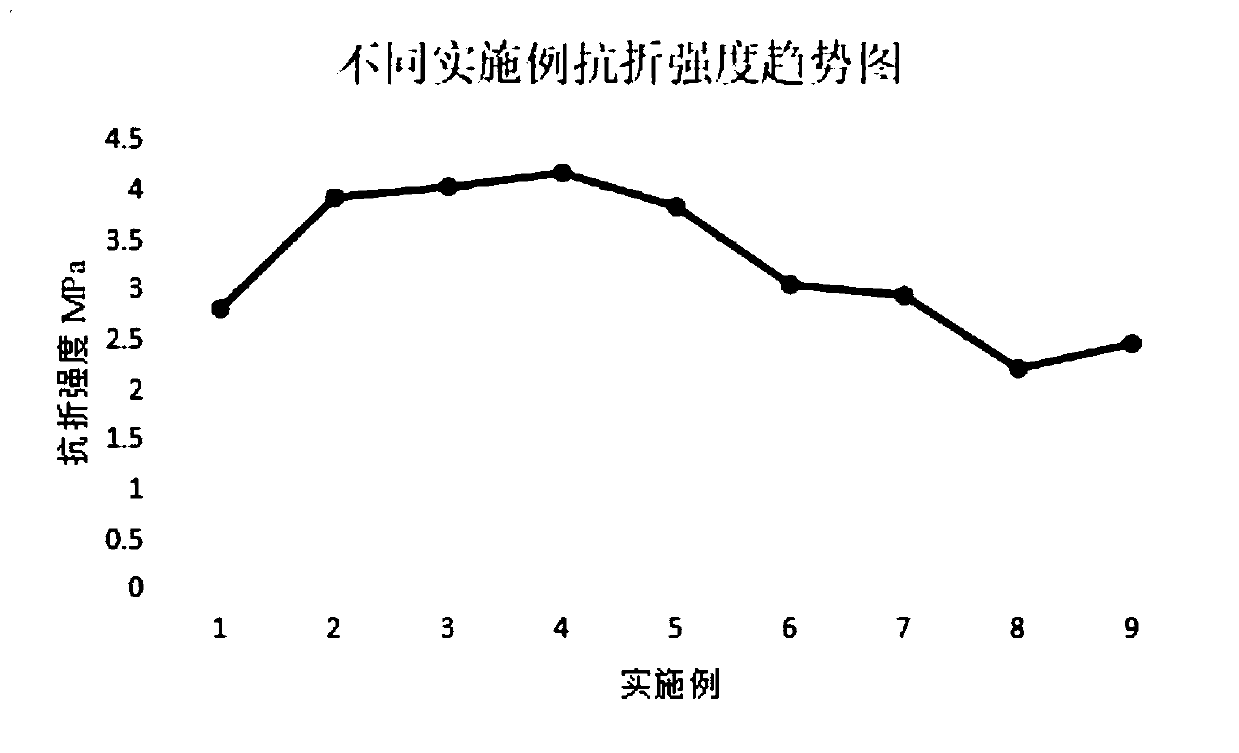

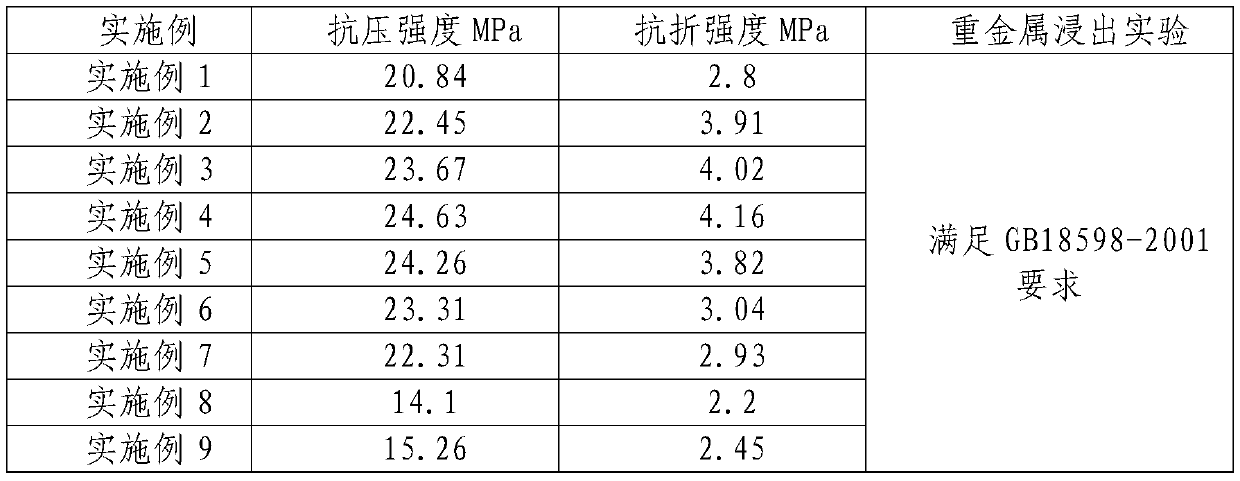

Examples

Embodiment 1

[0051] The raw materials for preparing autoclaved lime-sand bricks are: 20% fly ash, 20% carbide slag, 5% modifier 1, 8% modifier 2, 12% tailings and 35% aggregate ( Construction waste+coarse slag ash+sludge, in the aggregate, construction waste accounts for 50% by weight, coarse slag ash accounts for 30% by weight, and sludge accounts for 20% by weight).

[0052] The composition of the modifier 1 is calcium oxide: 0.5%, aluminum oxide: 0.2%, free sodium is less than 0.04%, the rest is silicon dioxide, and its loss on ignition is 2%, and the moisture content is less than 0.5%. %; the particle size of the modifier 1 is 0.045mm square hole sieve, %, and the fineness is greater than 12;

[0053] The composition of the modifier 2 is aluminum oxide: 40%, silicon dioxide: 35%, iron oxide: 4%, the rest is calcium oxide, and its loss on ignition is not more than 8%. at 15%.

[0054] The preparation method is as follows: the above-mentioned components are mixed, pressed into bricks b...

Embodiment 2

[0056] The raw materials for preparing autoclaved lime-sand bricks are: 20% fly ash, 18% carbide slag, 7% modifier 1, 10% modifier 2, 10% tailings and 35% aggregate ( Construction waste+coarse slag ash+sludge, in the aggregate, construction waste accounts for 50% by weight, coarse slag ash accounts for 35% by weight, and sludge accounts for 15% by weight). The composition of the modifying agent 1 and modifying agent 2 is the same as that in Example 1.

[0057] The preparation method is as follows: the above-mentioned components are mixed, pressed into bricks by a Lasko hydraulic brick machine imported from Germany, the pressure of the brick machine is 125 bar, and steamed in an autoclave to obtain an autoclaved lime-sand brick. The steam curing process is saturated steam 1.0Mpa, temperature: 180°C, and constant pressure for 4 hours.

Embodiment 3

[0059] The raw materials for preparing autoclaved lime-sand bricks are: 20% fly ash, 18% carbide slag, 10% modifier 1, 10% modifier 2, 7% tailings and 35% aggregate ( Construction waste+coarse slag ash+sludge, in the aggregate, construction waste accounts for 45% by weight, coarse slag ash accounts for 35% by weight, and sludge accounts for 20% by weight). The composition of the modifying agent 1 and modifying agent 2 is the same as that in Example 1.

[0060] The preparation method is as follows: the above-mentioned components are mixed, pressed into bricks by a Lasko hydraulic brick machine imported from Germany, the pressure of the brick machine is 125 bar, and steamed in an autoclave to obtain an autoclaved lime-sand brick. The steam curing process is saturated steam 1.0Mpa, temperature: 180°C, and constant pressure for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com