Clay slurry curing agent

A technology of curing agent and clay slurry is applied in the field of clay slurry curing agent, which can solve the problems of increased cost of curing agent and low strength of stone body, and achieves the effects of increasing mechanical strength and increasing cross-linking density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A: Prepare clay slurry with a slurry density of 1.30g / cm 3 , the sand content is 7%, and the clay is dominated by silty clay.

[0016] B: Curing agent ratio: cement: mineral powder = 1:2, the mineral powder is made of steel slag powder and water-quenched slag powder.

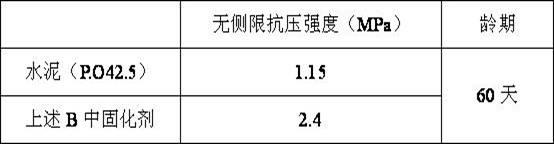

[0017] Use 300g of cement and the above-mentioned curing agent. Under the same conditions, 1200g of clay slurry is respectively cured. The results are shown in the table below.

[0018] Table 1 adopts cement and curing agent in the present invention to solidify clay slurry gained strength

[0019]

Embodiment 2

[0021] A: Prepare clay slurry with a slurry density of 1.30g / cm 3 , the sand content is 7%, and the clay is dominated by silty clay.

[0022] B: Curing agent ratio: cement: mineral powder: activator: auxiliary agent = 1:1:0.02: 0.01.

[0023] The slag is water-quenched blast furnace slag, the activator is calcium sulfate, and the auxiliary agent is sodium pyrophosphate.

[0024] Using 300g of cement and the above-mentioned curing agent, under the same conditions, 1200g of clay slurry was respectively cured, and the results obtained are shown in Table 2 below.

[0025] Table 2 adopts cement and curing agent in the present invention to solidify clay slurry gained strength

[0026]

Embodiment 3

[0028] A: Prepare clay slurry with a slurry density of 1.50g / cm 3 , the sand content is 2%, and the clay is dominated by silty clay.

[0029] B: Curing agent ratio: cement: mineral powder: activator: auxiliary agent = 1:10:0.1:0.01.

[0030] The slag is water-quenched blast furnace slag and boiling furnace slag (mass ratio 1:1), the activator is sodium sulfate, and the auxiliary agent is naphthalenesulfonate formaldehyde condensate.

[0031] Using 300g of cement and the above-mentioned curing agent, under the same conditions, 1200g of clay slurry was respectively cured, and the results are shown in Table 3 below.

[0032] Table 3 adopts cement and curing agent in the present invention to solidify clay slurry gained strength

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com