Preparation method of poly-silicon iron manganese graphene flocculant

A graphene and ferrosilicon technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc., can solve the problems of high treatment difficulty, poor effect, easy hydrolysis of flocculants, etc. Low requirements for preparation conditions, simple preparation process and wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Influence of the mass ratio of graphite powder and polysilicic acid on the effect of preparing flocculant to treat landfill leachate

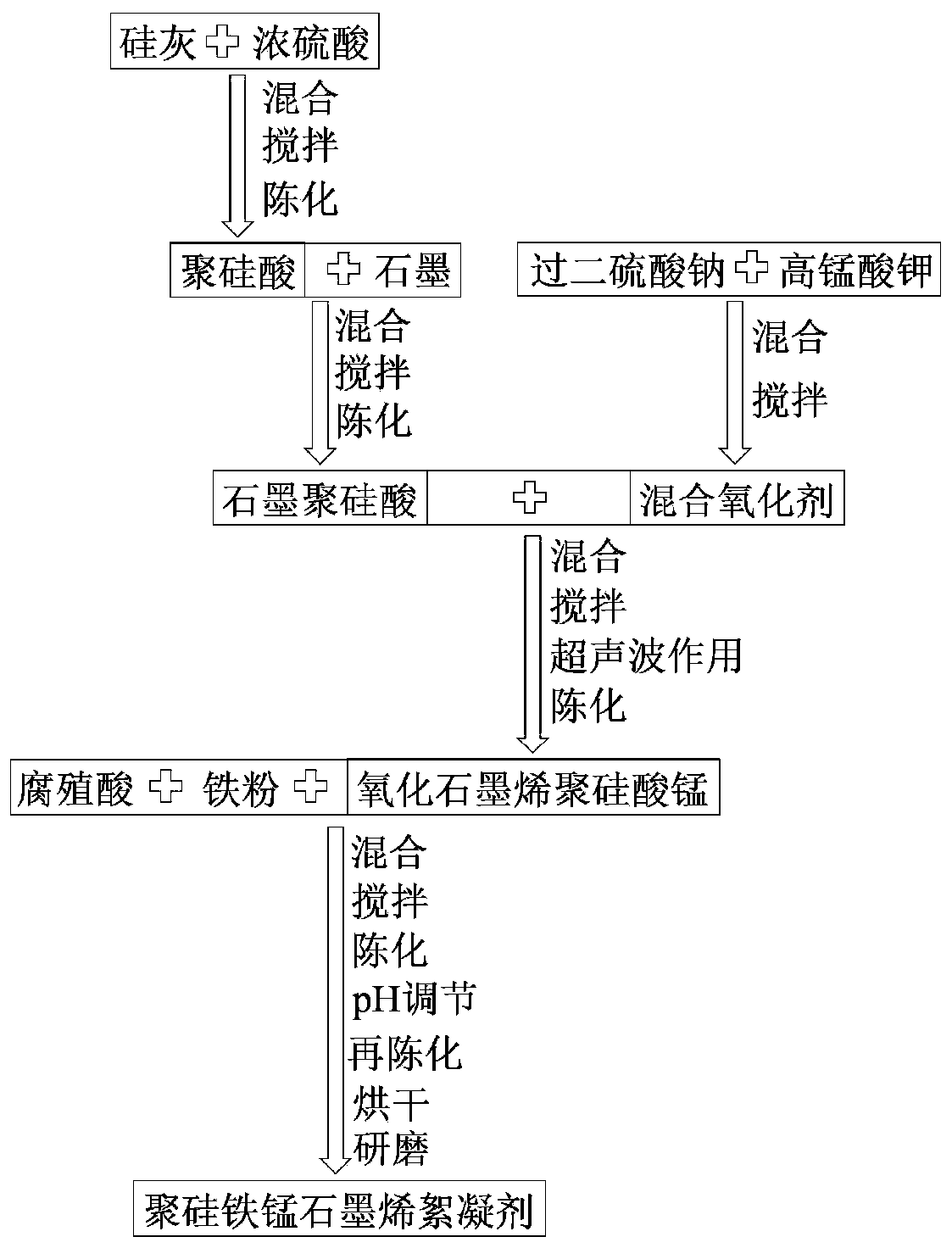

[0023] Preparation of polysilicon ferromanganese graphene flocculant: as figure 1 As shown, weigh silica fume and concentrated sulfuric acid according to the solid-to-liquid ratio of 1:1 (mg:mL), mix, stir evenly, and age for 3 hours to obtain polysilicic acid, wherein the mass fraction of concentrated sulfuric acid is 70%; according to graphite Powder and polysilicic acid mass ratio 2.5:100, 3.5:100, 4.5:100, 5:100, 15:100, 25:100, 26:100, 28:100, 30:100 Weigh graphite powder and polysilicon respectively acid, mixed, stirred evenly, and aged for 3 hours to obtain graphite polysilicate; weigh sodium peroxodisulfate and potassium permanganate according to the mass ratio of sodium peroxodisulfate and potassium permanganate 10:100, mix, stir evenly, Obtain a mixed oxidant; weigh the mixed oxidant and graphite polysilicate according to the ...

Embodiment 2

[0040] Effect of the mass ratio of sodium persulfate and potassium permanganate on the effect of preparing flocculant to treat landfill leachate

[0041] Preparation of polysilicon ferromanganese graphene flocculant: Weigh silica fume and concentrated sulfuric acid according to the solid-to-liquid ratio of 1:1.5 (mg:mL), mix, stir evenly, and age for 4.5 hours to obtain polysilicic acid, of which concentrated sulfuric acid The mass fraction is 80%; take graphite powder and polysilicic acid according to the mass ratio of graphite powder and polysilicic acid 25:100, mix, stir evenly, and age for 4.5 hours to obtain graphite polysilicic acid; according to sodium peroxodisulfate and high Potassium manganate mass ratio 5:100, 7:100, 9:100, 10:100, 15:100, 20:100, 21:100, 23:100, 25:100 Weigh sodium persulfate and permanganese respectively Potassium acid potassium, mix, stir evenly, get mixed oxidant; Take mixed oxidant and graphite polysilicic acid according to the mass ratio of mi...

Embodiment 3

[0048] Effect of mass ratio of humic acid, iron powder and graphene oxide polysilicate manganese on the effect of preparing flocculant to treat landfill leachate

[0049] Preparation of polysilicon ferromanganese graphene flocculant: Weigh silica fume and concentrated sulfuric acid according to the solid-to-liquid ratio of 1:2 (mg:mL), mix, stir evenly, and age for 6 hours to obtain polysilicic acid, of which concentrated sulfuric acid The mass fraction is 90%; take graphite powder and polysilicic acid according to the mass ratio of graphite powder and polysilicic acid 25:100, mix, stir evenly, and age for 6 hours to obtain graphite polysilicic acid; according to sodium peroxodisulfate and high Potassium manganate mass ratio 20:100 Weigh sodium peroxodisulfate and potassium permanganate, mix and stir evenly to obtain mixed oxidant; weigh mixed oxidant and graphite polysilicate according to the mass ratio of mixed oxidant and graphite polysilicate 30:100 Acid, mixed, stirred ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com