Method for treating medical waste liquid by utilizing electron beam irradiation technology

A technical treatment, electron beam radiation technology, applied in the field of medical waste liquid treatment, can solve the problems of mutual interference of active particles, achieve the effect of improved electron beam irradiation technology, simple treatment method, and easy access to reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

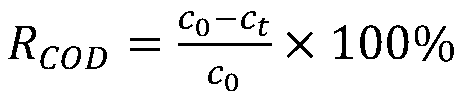

[0018] Effect of Sodium Peroxodisulfate and Medical Wastewater Solid-Liquid Ratio on COD Removal Efficiency of Electron Beam Irradiation Treatment of Medical Wastewater

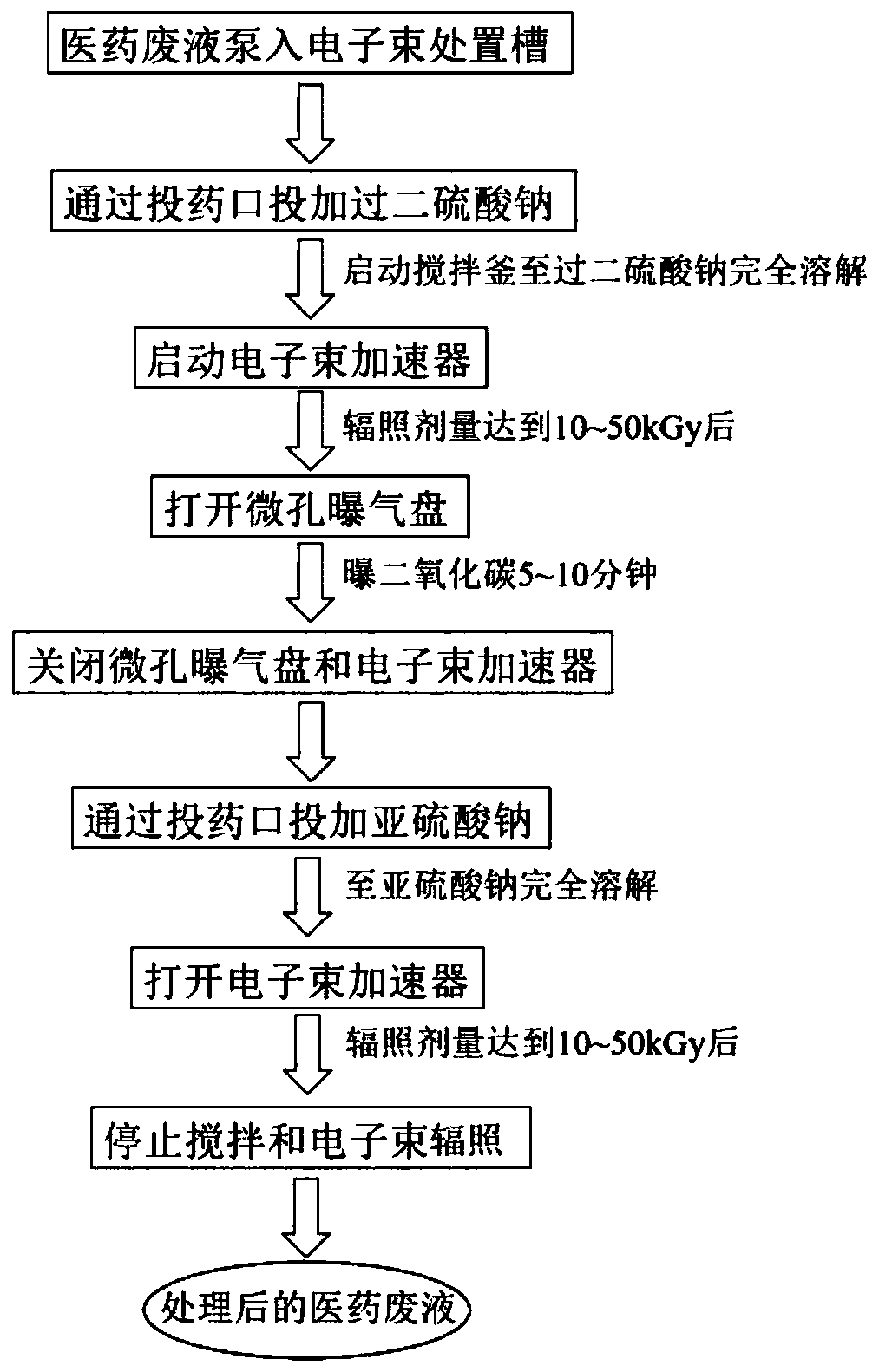

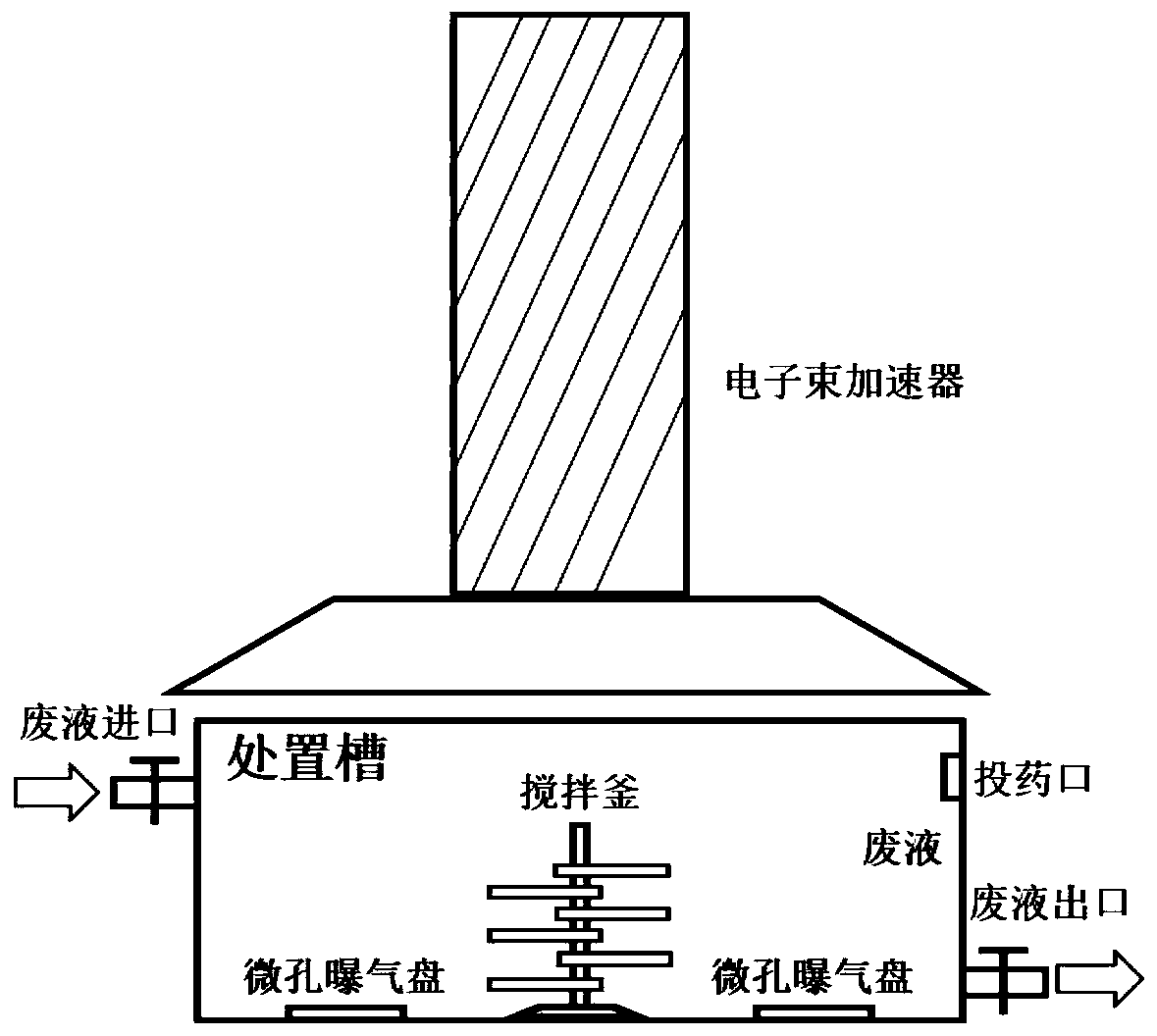

[0019] Treatment of medical wastewater by electron beam irradiation: see the treatment process figure 1 According to the solid-liquid ratio of sodium persulfate and medical wastewater 0.005:1mg / mL, 0.006:1mg / mL, 0.008:1mg / mL, 0.01:1mg / mL, 0.03:1mg / mL, 0.05:1mg / mL, 0.055: 1mg / mL, 0.06:1mg / mL, 0.07:1mg / mL respectively weigh sodium persulfate and pharmaceutical wastewater. Weigh sodium sulfite according to the solid-to-liquid ratio of sodium sulfite to pharmaceutical wastewater 0.02:1mg / mL. Pump the medical waste liquid from the waste liquid inlet into the electron beam disposal tank ( figure 2 ), then add sodium peroxodisulfate through the dosing port, start the stirring tank, stir under 20rpm speed conditions, and start the electron beam accelerator after the sodium peroxodisulfate is completely dissolved. ...

Embodiment 2

[0026] Effect of sodium sulfite and medical wastewater solid-liquid ratio on the COD removal rate of electron beam irradiation treatment of medical wastewater

[0027]Electron beam irradiation treatment of medical wastewater: Weigh sodium peroxodisulfate and medical wastewater according to the solid-to-liquid ratio of sodium peroxodisulfate and medical wastewater 0.05:1 mg / mL, respectively. According to the solid-to-liquid ratio of sodium sulfite and pharmaceutical wastewater 0.01:1mg / mL, 0.015:1mg / mL, 0.018:1mg / mL, 0.02:1mg / mL, 0.04:1mg / mL, 0.06:1mg / mL, 0.065:1mg / mL, 0.07:1mg / mL, 0.08:1mg / mL were weighed sodium sulfite. Pump the medical waste liquid into the electron beam disposal tank, then add sodium peroxodisulfate through the injection port, start the stirring tank, stir at a speed of 35rpm, and start the electron beam accelerator after the sodium peroxodisulfate is completely dissolved. After the irradiation dose reaches 30kGy, open the microporous aeration pan, aerate ...

Embodiment 3

[0033] Effect of carbon dioxide gas exposure time on the COD removal rate of electron beam irradiation treatment of medical waste liquid

[0034] Electron beam irradiation treatment of medical wastewater: Weigh sodium peroxodisulfate and medical wastewater according to the solid-to-liquid ratio of sodium peroxodisulfate and medical wastewater 0.05:1 mg / mL, respectively. Weigh sodium sulfite according to the solid-to-liquid ratio of sodium sulfite to pharmaceutical wastewater 0.06:1mg / mL. Pump the medical waste liquid into the electron beam disposal tank, then add sodium peroxodisulfate through the injection port, start the stirring tank, stir at a speed of 50rpm, and start the electron beam accelerator after the sodium peroxodisulfate is completely dissolved. After the irradiation dose reaches 50kGy, open the microporous aeration disc, aerate carbon dioxide for 2.5 minutes, 3.5 minutes, 4.5 minutes, 5 minutes, 7.5 minutes, 10 minutes, 10.5 minutes, 11.5 minutes, 12.5 minutes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com