Method for removing butyl p-hydroxybenzoate by activating persulfate with layered MoS2 and application thereof

A technology of butyl hydroxybenzoate and activated persulfate, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of easy storage and transportation, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

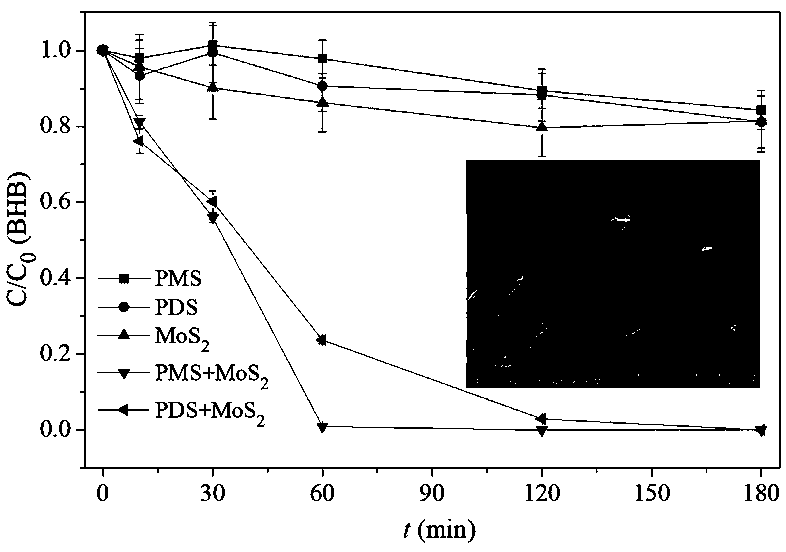

[0021] (1) Layered MoS 2 Activation of PMS and PDS to remove BHB in water: prepare a BHB aqueous solution with a concentration of 5 mg / L, and adjust its pH to ~ 7.00. Measure 80 mL of BHB aqueous solution in a clean reaction bottle, add MoS after numbering 2 (1 g / L), PMS (5 mM) or PDS (5 mM), placed at room temperature (25±2°C) and stirred (300 rpm) for 180 min, and 2 mL water samples were taken at regular intervals for analysis.

Embodiment 2

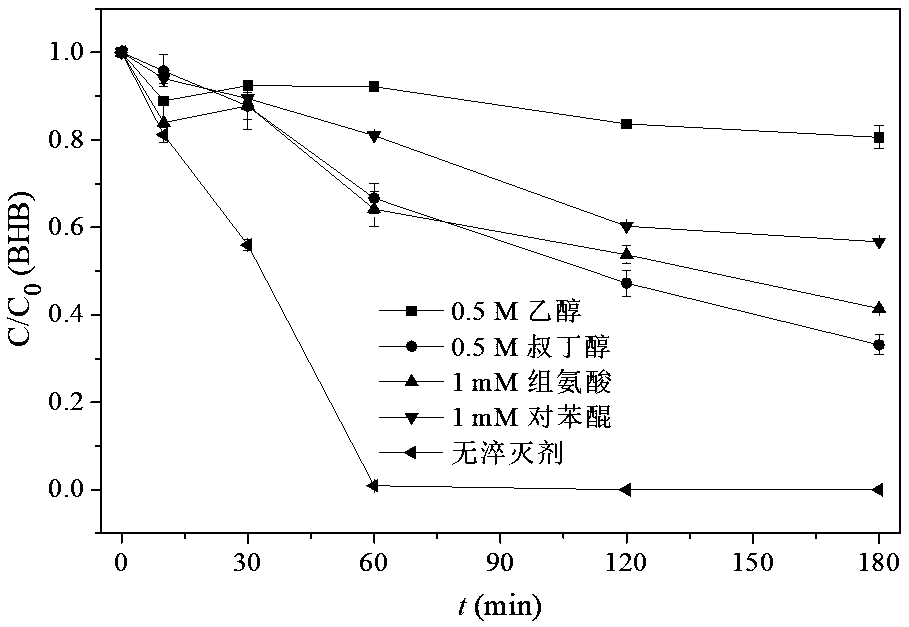

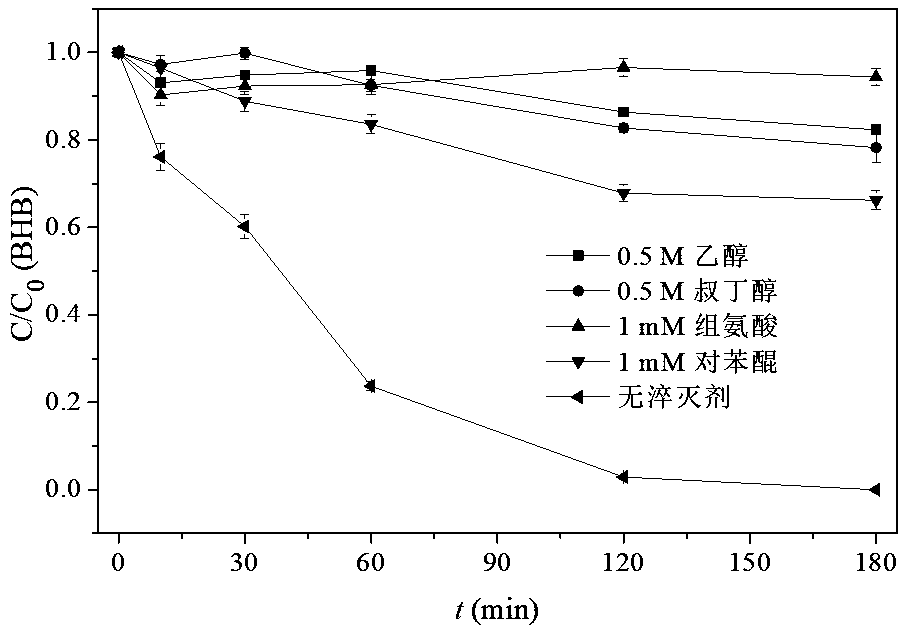

[0024] (1) Investigation of the effect of different quenchers on layered MoS 2 Effect of activated PMS and PDS on removing BHB from water and analysis of active species: Prepare a BHB aqueous solution with a concentration of 5 mg / L and adjust its pH to ~ 7.00. Measure 80 mL of BHB aqueous solution in a clean reaction bottle, add MoS after numbering 2 (1 g / L), PMS (5 mM) or PDS (5 mM); no quencher was added to the control sample, and 0.5 M ethanol, 0.5 M tert-butanol, 1 mM histidine or 1 mM para Benzoquinone, then put it at room temperature (25±2°C) and stir (300rpm) for 180 minutes, and take 2mL water samples at regular intervals for analysis.

[0025] (2) Draw the obtained data into a graph, such as figure 2 Shown: 0.5 M ethanol and 0.5 M tert-butanol for MoS 2 The / PMS system showed an inhibitory effect on the removal of BHB, and the inhibitory effect of 0.5 M ethanol was stronger than that of 0.5 M tert-butanol, indicating that MoS 2 / PMS system exists SO 4 •‒ and •...

Embodiment 3

[0027] (1) To investigate the effect of different initial pH, PMS / PDS dosage and temperature on layered MoS 2 The effect of activating PMS and PDS on the removal of BHB from water: Prepare a BHB aqueous solution with a concentration of 5 mg / L and adjust its pH to 3-10. Measure 80 mL of BHB aqueous solution in a clean reaction bottle, add MoS after numbering 2 (1 g / L), PMS (2.5 ~ 7.5 mM) or PDS (2.5 ~ 7.5mM), then put it at room temperature (15 ~ 40 ℃) and stir (300 rpm) for 180 min, and take 2mL water samples at regular intervals. analyze. The analysis data shows that in the range of pH 3 ~ 10, after 180 min of reaction, more than 80% of BHB can be absorbed by MoS 2 / PMS and MoS 2 / PDS system oxidation removal; pH ≈ 7, when the dosage of PMS and PDS changes from 2.5 to 7.5 mM, the oxidation removal rate of BHB can reach more than 98% after 180 min; increasing the solution temperature is beneficial to MoS 2 / PMS and MoS 2 / PDS system quickly removes BHB in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com