Method for synchronously achieving incineration fly ash detoxification and chromium slag reduction curing

A technology for incinerating fly ash and chromium slag, which is applied in the field of hazardous solid waste treatment, can solve the problems of large consumption of leaching agent, low strength, and non-uniform pollutant enrichment areas, etc., and achieves simple treatment methods and binding capabilities Strong, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

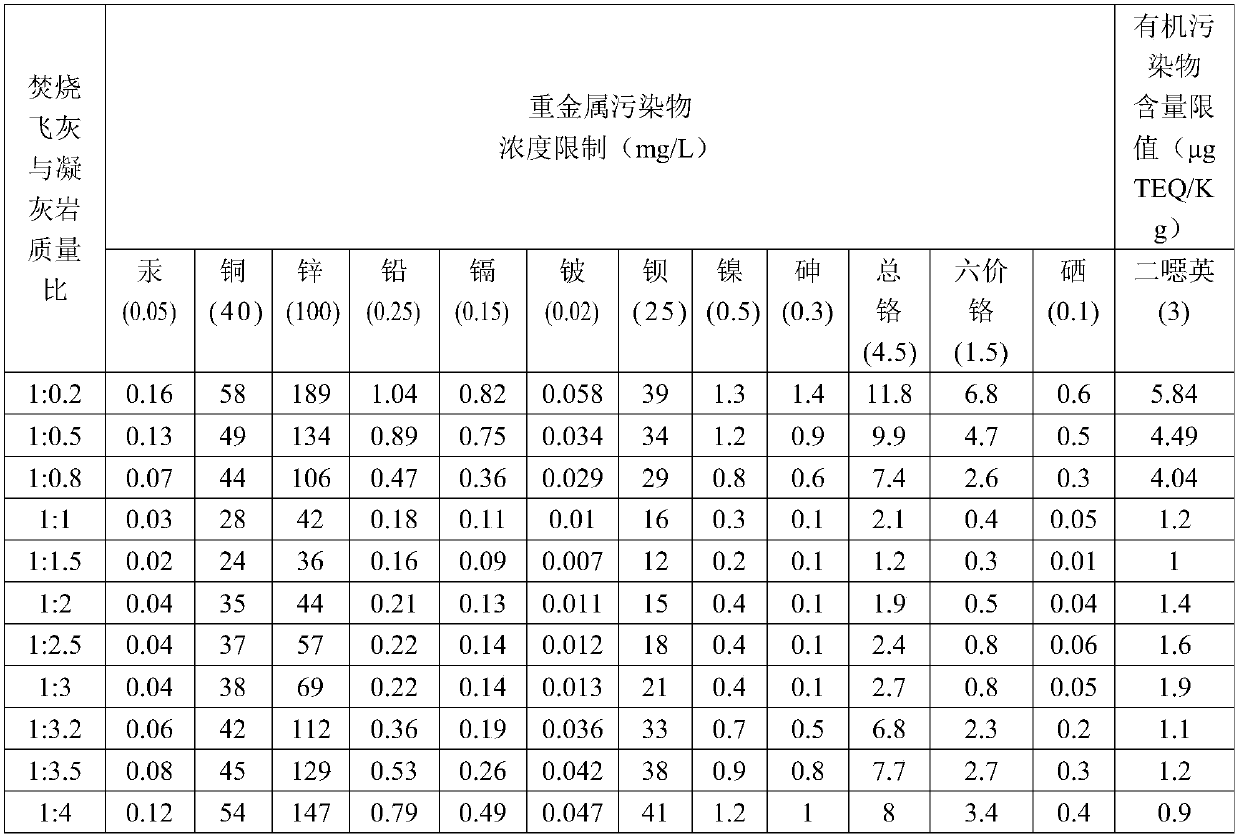

[0024] Influence of the mass ratio of incineration fly ash to tuff on simultaneous detoxification of incineration fly ash and reduction and solidification of chromium slag:

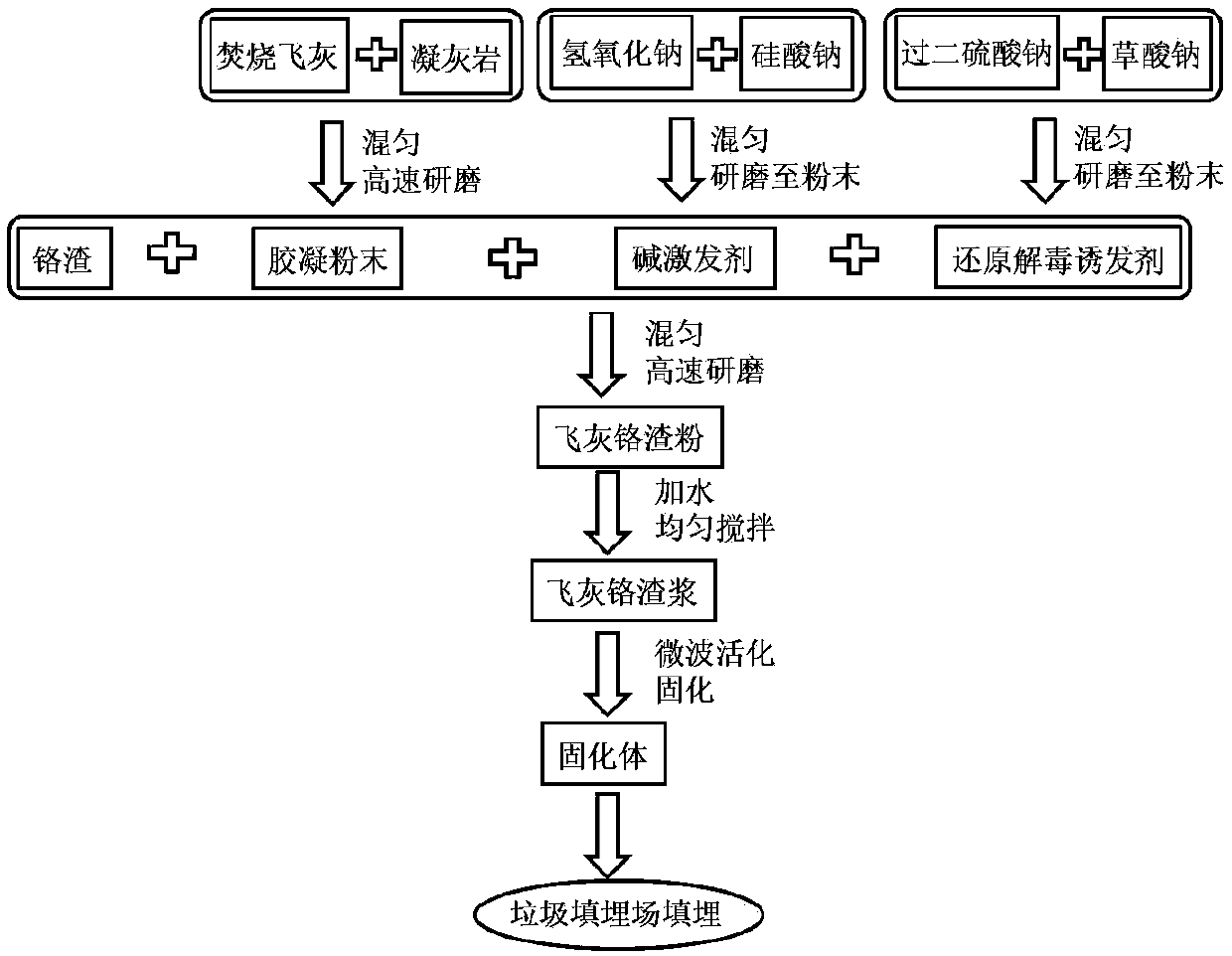

[0025] Such as figure 1 As shown, the mass ratio of incineration fly ash to tuff is 1:0.2, 1:0.5, 1:0.8, 1:1, 1:1.5, 1:2, 1:2.5, 1:3, 1:3.2, 1 :3.5, 1:4, respectively weigh incineration fly ash and tuff, mix evenly, and grind at high speed for 1 hour to obtain gelled powder. According to the mass ratio of sodium hydroxide and sodium silicate of 1:3, weigh sodium hydroxide and sodium silicate respectively, mix them uniformly, and grind them into powder to obtain the alkali activator. According to the mass ratio of sodium peroxodisulfate and sodium oxalate 1:5, weigh sodium peroxodisulfate and sodium oxalate respectively, mix them evenly, and grind them into powder to obtain a reduction detoxification inducer. According to the mass ratio of chromium slag, gelling powder, alkali activator, reduction detoxi...

Embodiment 2

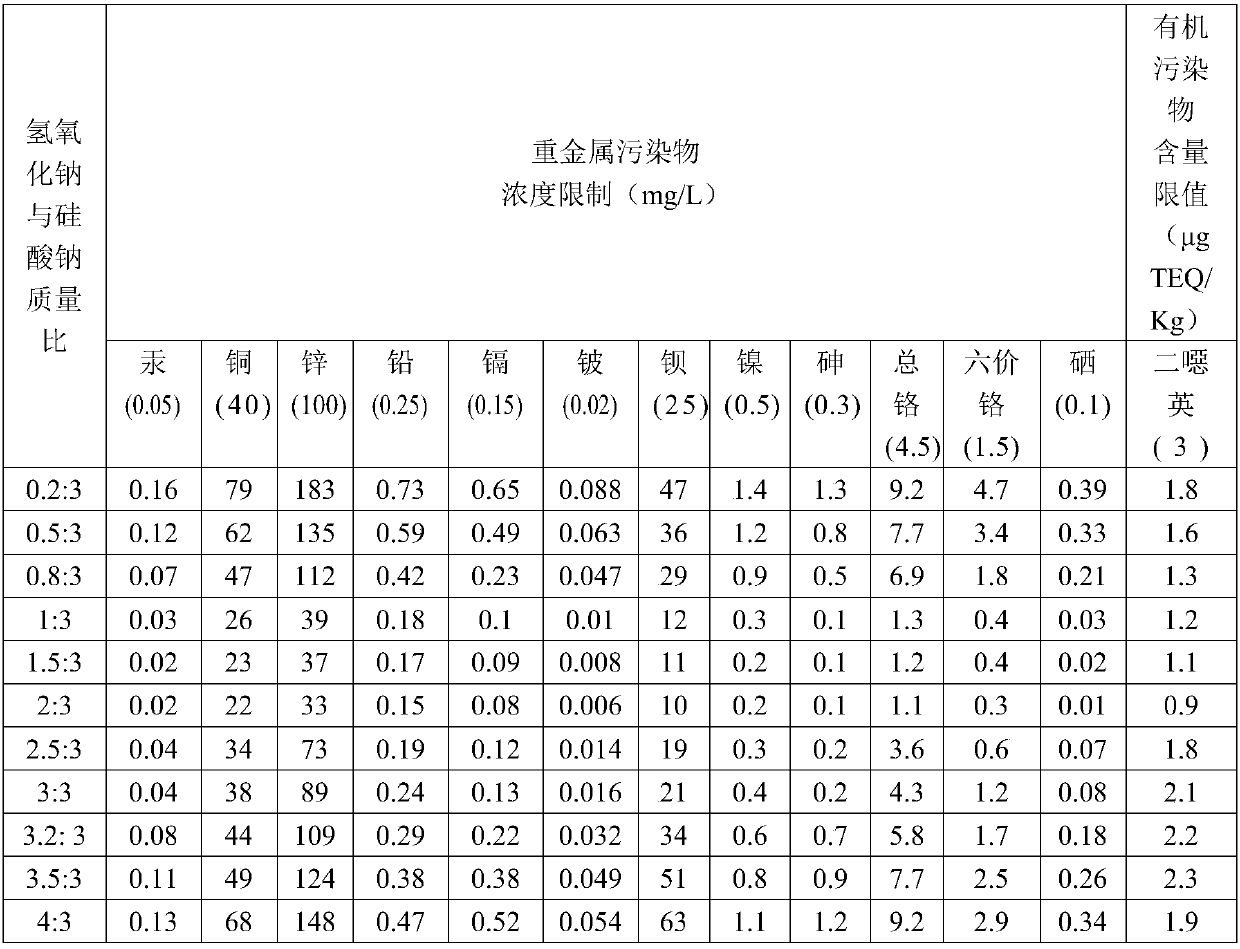

[0031] The effect of the mass ratio of sodium hydroxide to sodium silicate on simultaneous detoxification of incineration fly ash and reduction and solidification of chromium slag:

[0032]According to the mass ratio of incineration fly ash and tuff being 1:1.5, the incineration fly ash and tuff were weighed respectively, mixed evenly, and ground at high speed for 3 hours to obtain gelled powder. According to the mass ratio of sodium hydroxide to sodium silicate 0.2:3, 0.5:3, 0.8:3, 1:3, 1.5:3, 2:3, 2.5:3, 3:3, 3.2:3, 3.5:3, 4:3, weigh sodium hydroxide and sodium silicate respectively, mix them evenly, and grind them into powder to obtain the alkali activator. According to the mass ratio of sodium peroxodisulfate and sodium oxalate 3:5, weigh sodium peroxodisulfate and sodium oxalate respectively, mix them evenly, and grind them into powder to obtain a reduction detoxification inducer. According to the mass ratio of chromium slag, gelling powder, alkali activator, and reducti...

Embodiment 3

[0038] Effects of the mass ratio of sodium persulfate to sodium oxalate on simultaneous detoxification of incineration fly ash and reduction and solidification of chromium slag:

[0039] According to the mass ratio of incineration fly ash and tuff being 1:1.5, the incineration fly ash and tuff were weighed respectively, mixed evenly, and ground at high speed for 5 hours to obtain gelled powder. According to the mass ratio of sodium hydroxide and sodium silicate of 2:3, weigh sodium hydroxide and sodium silicate respectively, mix them uniformly, and grind them into powder to obtain the alkali activator. According to the mass ratio of sodium persulfate to sodium oxalate 0.2:5, 0.5:5, 0.8:5, 1:5, 2:5, 3:5, 4:5, 5:5, 5.2:5, 5.5:5, 6:5, weigh sodium peroxodisulfate and sodium oxalate respectively, mix them evenly, and grind them into powder to obtain the reduction and detoxification inducer. According to the mass ratio of chromium slag, gelling powder, alkali activator, reduction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com