Liquid composition for removing titanium nitride, semiconductor-element cleaning method using same, and semiconductor-element manufacturing method

一种液体组合物、化合物的技术,应用在钨和低介电常数层间绝缘膜的液体组合物,半导体元件的制造领域,能够解决钨防腐蚀效果不充分、氮化钛去除性低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

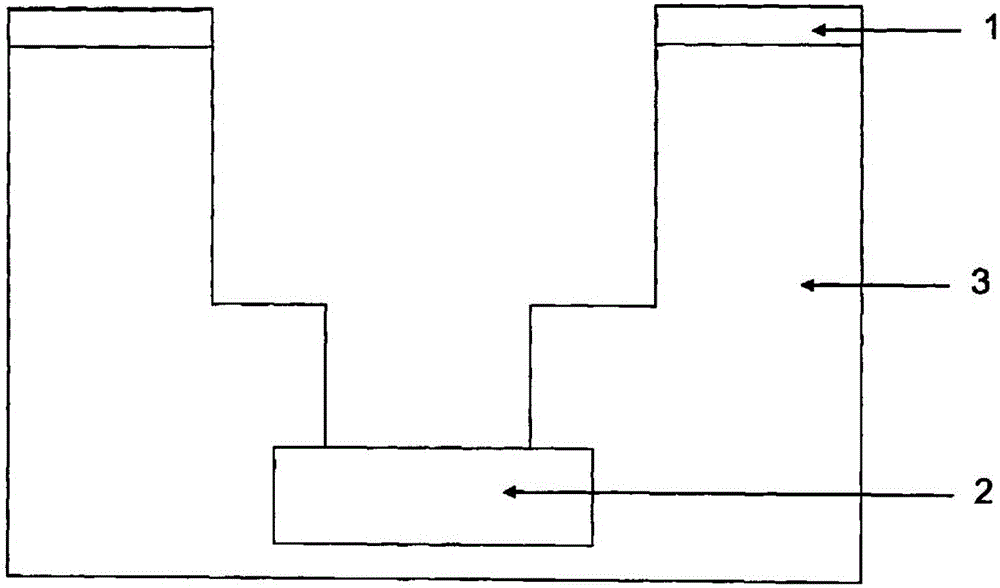

Image

Examples

Embodiment 1

[0190] 8.53 kg of pure water, 1.0 kg of 0.02 mol / L potassium permanganate solution (manufactured by Wako Pure Chemical Industries, Ltd., special grade, molecular weight 158.03) as component (A) and 1.0 kg as (B) were put into a polypropylene container with a capacity of 10 L. 40 mass % ammonium fluoride solution (manufactured by Morita Chemical Industry Co., Ltd., semiconductor grade, molecular weight 37.04) 0.0375 kg of components, Surflon S-241 (30 mass % product, trade name, AGC SEIMI CHEMICAL CO. ., LTD. perfluoroalkyl amine oxide) 0.0033kg, Phosphaol RS-710 (trade name, polyoxyethylene phosphate manufactured by Toho Chemical Industry Co., Ltd.) as (C2) component 0.001kg and (D) 0.426 kg of 47 mass % sulfuric acid (manufactured by Wako Pure Chemical Industries, Ltd., special grade, molecular weight 98.08) of the component. Stirring was performed to confirm the dissolution of each component, and a liquid composition was prepared. The resulting liquid composition had a pH o...

Embodiment 2~41

[0193] The washing|cleaning process was performed similarly to Example 1 except having prepared the liquid composition of the compounding quantity shown in Tables 1-7. The evaluation results are shown in Tables 1-7. SEM was used to observe the cross-section of the cleaned substrate. As a result, all substrates cleaned with the liquid composition had titanium nitride completely removed, and no corrosion of tungsten and low dielectric constant interlayer insulating films was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface pH | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com