Preparation method of ferrous-per-disulfide-based composite remover

A remover, iron disulfide technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as inability to achieve high-efficiency disposal goals, and achieve low chemical loss and low preparation costs , Efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

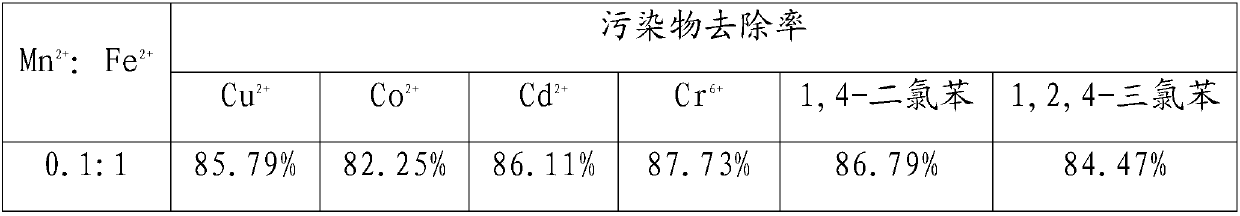

[0017] Example 1: Mn 2+ with Fe 2+ Effect of molar ratio on water treatment effect

[0018] In this case for Mn 2+ with Fe 2+ The molar ratio was tested to study the effect of the prepared remover on Cu in water 2+ 、Co 2+ 、Cd 2 + 、Cr 6+ , 1,4-dichlorobenzene, 1,2,4-trichlorobenzene removal rate.

[0019] According to Mn 2+ with Fe 2+ Molar ratio 0.1:1, 0.5:1, 0.8:1, 1:1, 1:2, 1:3, 1:4, 1:5, 1:5.5, 1:6 respectively weigh manganese sulfate and ferrous sulfate , mixed into water at the same time, and stirred until completely dissolved in a sealed state to obtain a mixed iron-manganese solution; press OH - with Fe 2+ Molar ratio 2:1 Weigh sodium hydroxide, mix it into water, and stir until completely dissolved in a sealed state to obtain lye; mix the lye into the mixed iron-manganese solution, and stir for 10 minutes in a sealed state to obtain iron-manganese two-phase hydrogen Oxide pulp; under the conditions of 30°C temperature and -0.08MPa relative vacuum, dry the ...

Embodiment 2

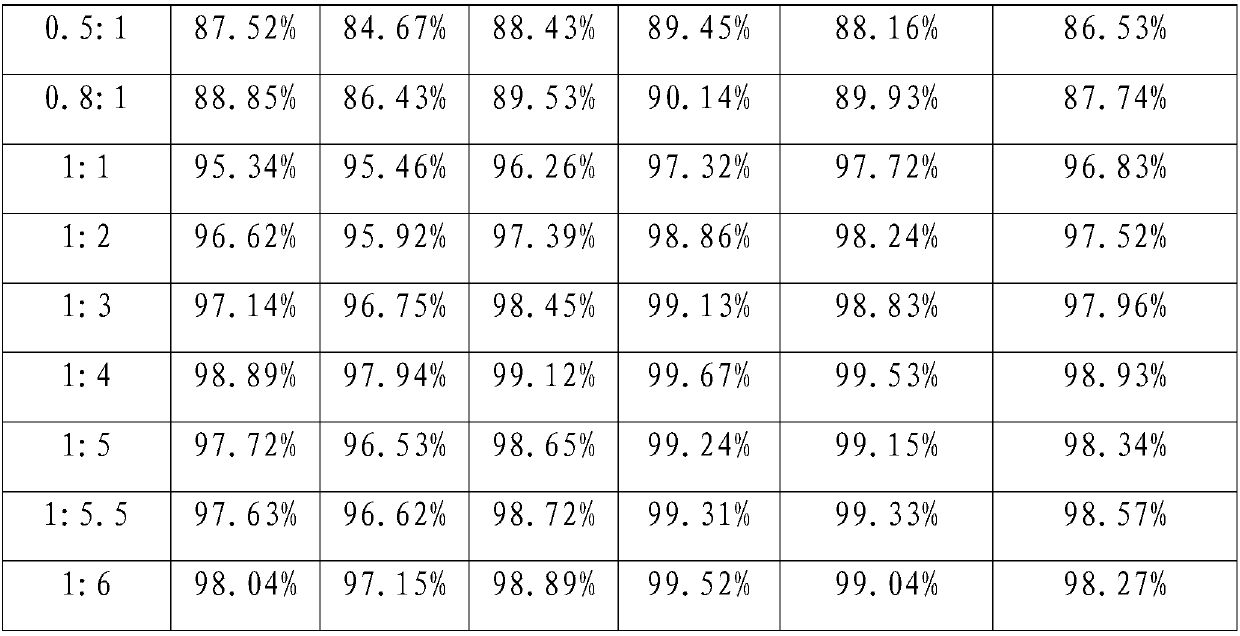

[0027] Example 2: OH - with Fe 2+ Effect of molar ratio on water treatment effect

[0028] In this case for OH - with Fe 2+ The molar ratio was tested to study the effect of the prepared remover on Cu in water 2+ 、Co 2+ 、Cd 2 + 、Cr 6+ , 1,4-dichlorobenzene, 1,2,4-trichlorobenzene removal rate.

[0029] According to Mn 2+ with Fe 2+ Weigh manganese sulfate and ferrous sulfate at a molar ratio of 1:4, mix them into water at the same time, and stir until completely dissolved in a sealed state to obtain a mixed iron-manganese solution. Press OH - with Fe 2+ Molar ratio 0.1:1, 0.5:1, 1:1, 1.5:1, 1.8:1, 2:1, 3:1, 3.2:1, 3.5:1, 3.8:1, 4:1, 4.2:1, 4.5:1, 4.8:1, 5:1, 5.5:1, 6:1 Weigh sodium hydroxide respectively, mix it into water, and stir until completely dissolved in a sealed state to obtain lye. The lye is mixed into the mixed iron-manganese solution, and stirred for 20 minutes in a sealed state to obtain iron-manganese two-phase hydroxide slurry. Under the conditio...

Embodiment 3

[0037] Embodiment 3: the influence of sodium peroxodisulfate addition amount on water body treatment effect

[0038] In this case, experiments were carried out on the mass ratio of sodium peroxodisulfate to iron-manganese two-phase hydroxide powder, and the effect of the removal agent on Cu in water was studied. 2+ 、Co 2+ 、Cd 2+ 、Cr 6+ , 1,4-dichlorobenzene, 1,2,4-trichlorobenzene removal rate.

[0039] According to Mn 2+ with Fe 2+ Weigh manganese sulfate and ferrous sulfate at a molar ratio of 1:4, mix them into water at the same time, and stir until completely dissolved in a sealed state to obtain a mixed iron-manganese solution. Press OH - with Fe 2+ The molar ratio is 3:1. Weigh sodium hydroxide, mix it into water, and stir until completely dissolved in a sealed state to obtain lye. The lye is mixed into the mixed iron-manganese solution, and stirred for 30 minutes in a sealed state to obtain iron-manganese two-phase hydroxide slurry. Under the conditions of temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com