Preparation method of wastewater remediation agent based on incineration fly ash

A technology for incinerating fly ash and repairing agents, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc. It can solve the problems of high disposal cost, low removal rate, secondary pollution, etc., and achieves a simple preparation method, The effect of cheap raw materials and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

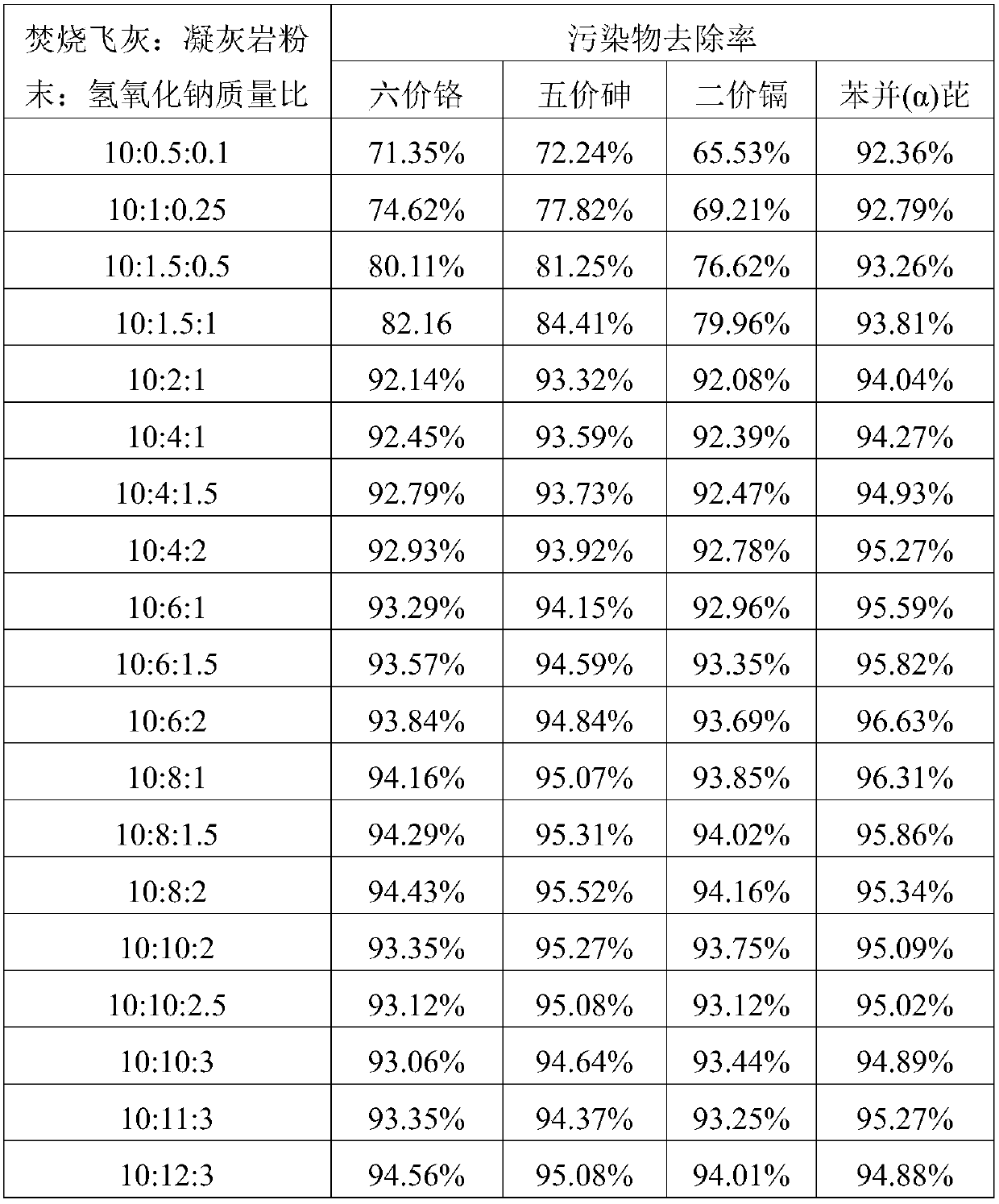

[0019] Effects of incineration fly ash, tuff powder and sodium hydroxide mass ratio on the removal of hexavalent chromium, pentavalent arsenic, divalent cadmium and benzo(α)pyrene in water:

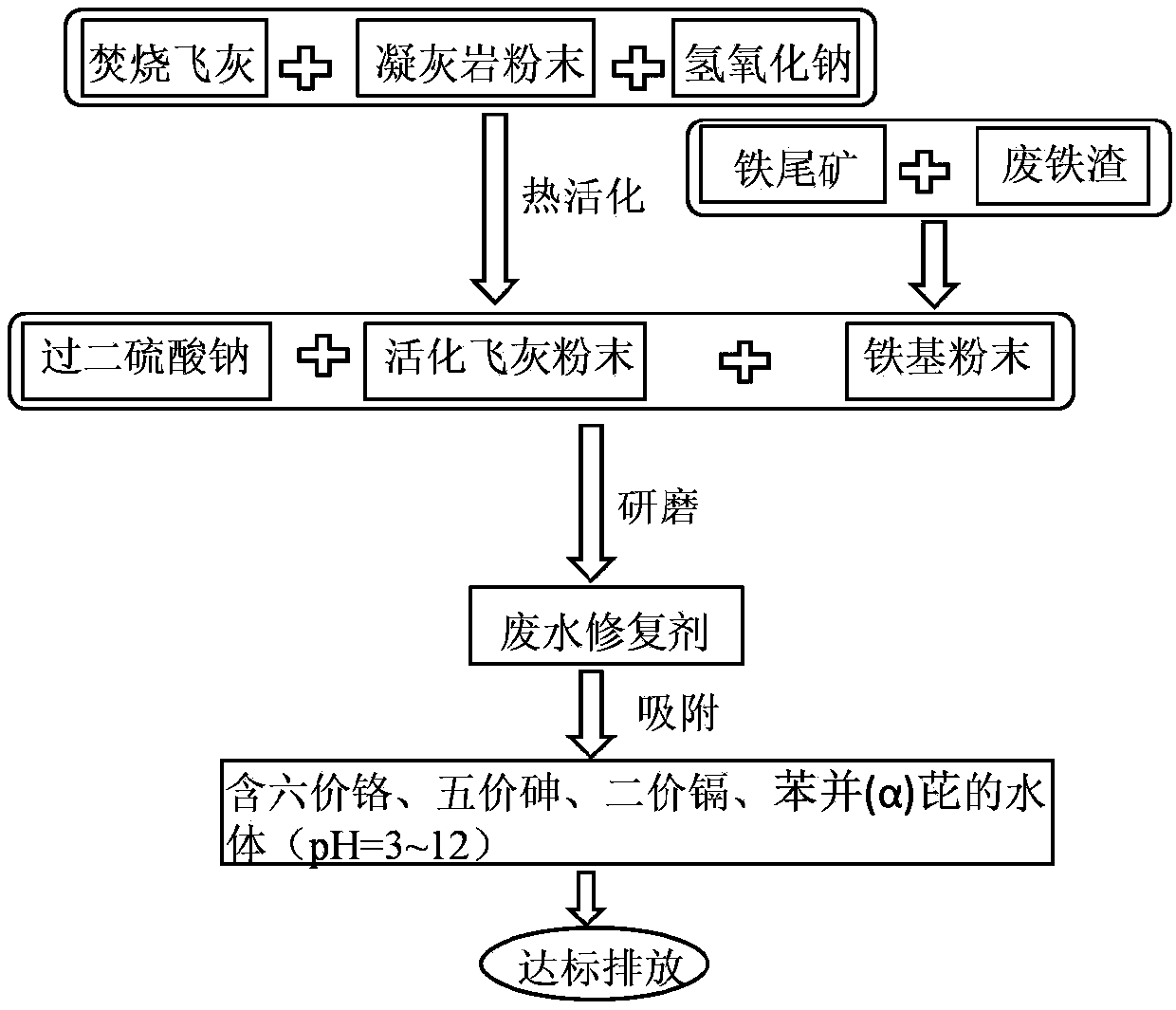

[0020] Such as figure 1 Shown, is the preparation process of waste water remediation agent, specifically: according to incineration fly ash, tuff powder, sodium hydroxide mass ratio is 10:0.5:0.1, 10:1:0.25, 10:1.5:0.5, 10:1.5: 1. 10:2:1, 10:4:1, 10:4:1.5, 10:4:2, 10:6:1, 10:6:1.5, 10:6:2, 10:8:1, 10:8:1.5, 10:8:2, 10:10:2, 10:10:2.5, 10:10:3, 10:11:3, 10:12:3, weigh incineration fly Ash, tuff powder and sodium hydroxide were mixed evenly, and then activated at 300°C for 2 hours to obtain activated fly ash powder; according to the mass ratio of iron tailings and scrap iron slag as 4:1, weigh iron tailings and Scrap iron slag, mix evenly, grind at high speed for 1 hour, cross 100 mesh sieves, obtain iron base powder; Ash powder, iron-based powder, and sodium peroxodisulfate are mixed ev...

Embodiment 2

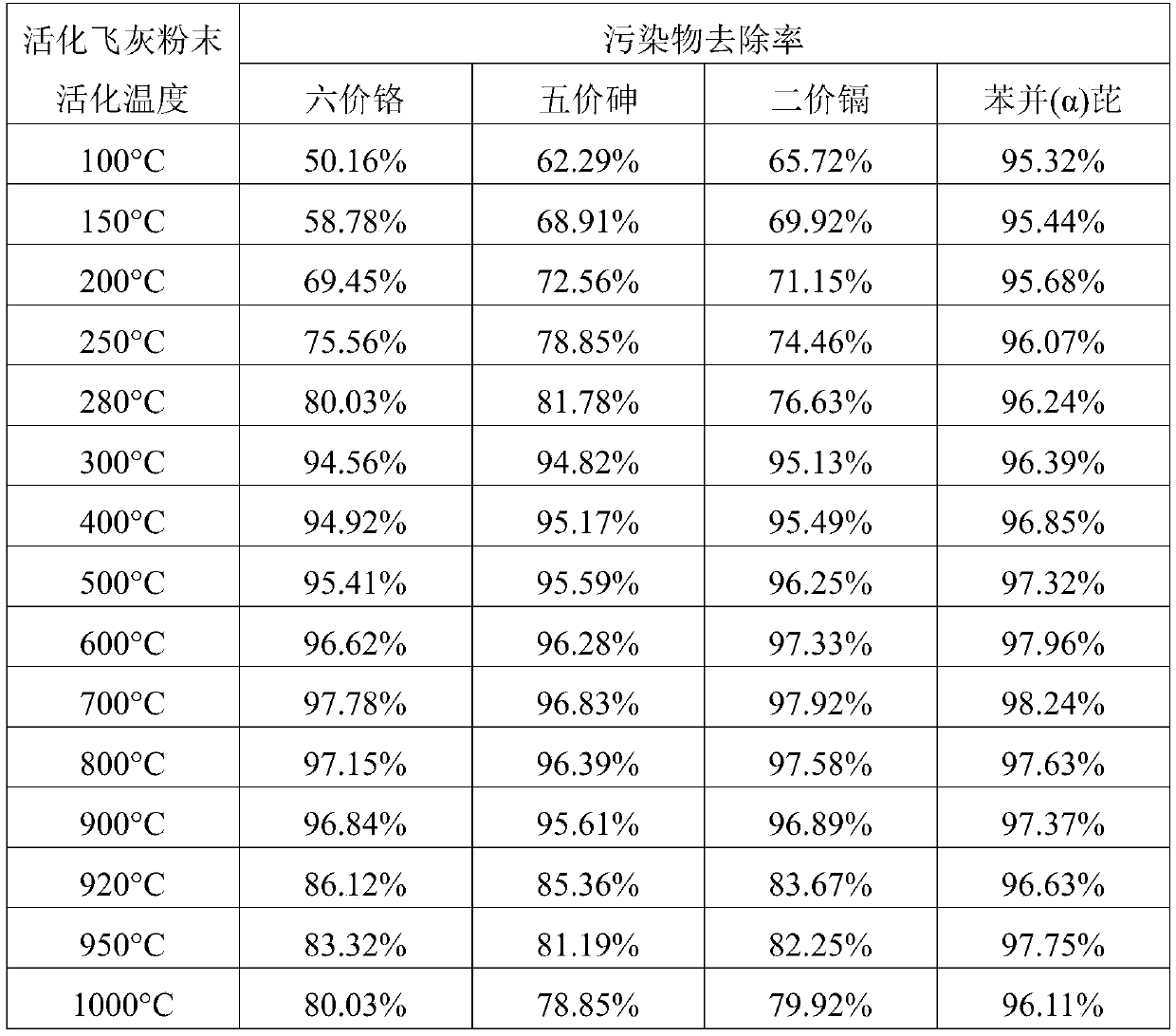

[0027] Effect of activated fly ash powder activation temperature on the removal of hexavalent chromium, pentavalent arsenic, divalent cadmium and benzo(α)pyrene in water:

[0028] According to the mass ratio of incineration fly ash, tuff powder, and sodium hydroxide as 10:6:2, weigh the corresponding mass of incineration fly ash, tuff powder, and sodium hydroxide, mix them evenly, and then heat them at 100°C, 150°C, and 200°C respectively. ℃, 250°C, 280°C, 300°C, 400°C, 500°C, 600°C, 700°C, 800°C, 900°C, 920°C, 950°C, 1000°C for 5 hours to obtain activated fly ash powder; The mass ratio of iron tailings and waste iron slag is 3:1, take iron tailings and waste iron slag respectively, mix uniformly, grind at high speed for 2.5 hours, cross 200 mesh sieves, obtain iron-based powder; press activated fly ash powder, The mass ratio of iron-based powder and sodium peroxodisulfate is 10:2:2. The activated fly ash powder, iron-based powder and sodium peroxodisulfate are weighed respect...

Embodiment 3

[0034] The effect of the mass ratio of iron tailings and scrap iron slag on the removal of hexavalent chromium, pentavalent arsenic, divalent cadmium and benzo(α)pyrene in water:

[0035] According to the mass ratio of incineration fly ash, tuff powder and sodium hydroxide as 10:6:2, weigh the corresponding mass of incineration fly ash, tuff powder and sodium hydroxide, mix them evenly, and then activate them at 700°C for 8 hours. The activated fly ash powder is obtained; the mass ratio of iron tailings and waste iron slag is 5:1, 4.5:1, 4.2:1, 4:1, 3.5:1, 3:1, 2.5:1, 2:1, 1.5:1, 1:1, 0.8:1, 0.5:1, 0.2:1, respectively weigh iron tailings and scrap iron slag, mix evenly, grind at high speed for 4 hours, and pass through a 300-mesh sieve to obtain iron-based powder; The mass ratio of activated fly ash powder, iron-based powder, and sodium peroxodisulfate is 10:3:3. Weigh the activated fly ash powder, iron-based powder, and sodium peroxodisulfate respectively, mix them evenly, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com