Composite membrane prepared by low-temperature plasma technology under normal pressure

A low-temperature plasma and plasma technology, applied in the field of composite membranes and composite membranes prepared by plasma technology, can solve the problems of poor environmental friendliness, achieve environmental friendliness, overcome vacuum equipment, ensure structural integrity and separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

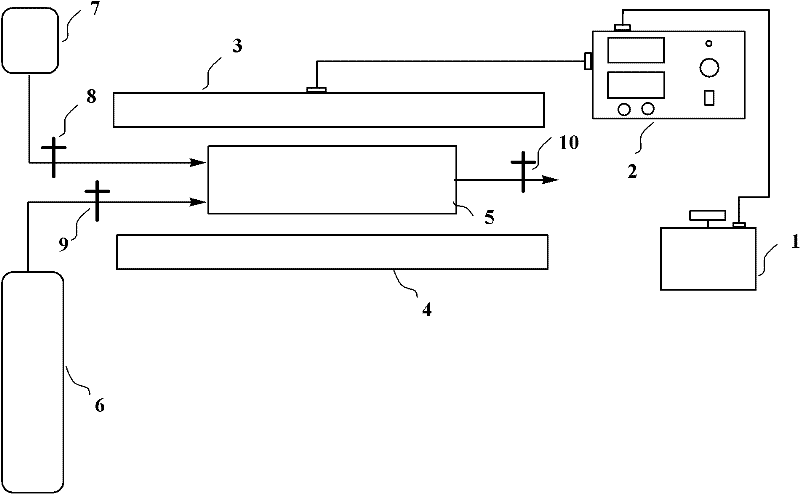

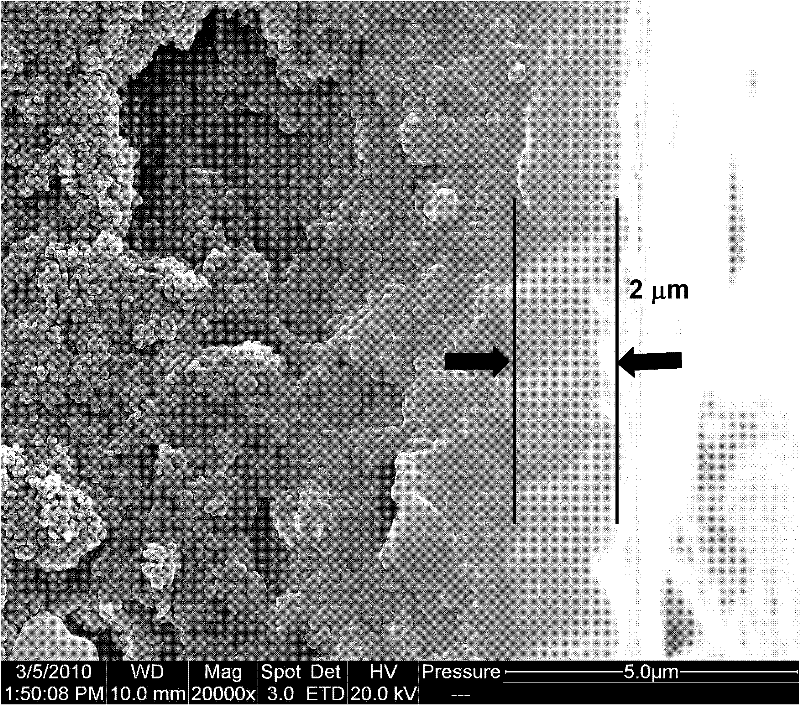

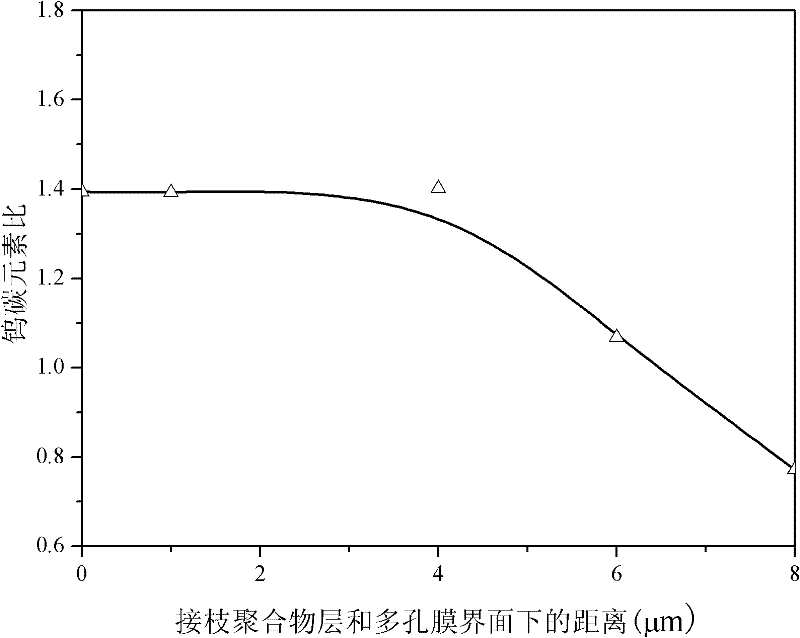

[0036] Select pure water flux 130L / m 2h bar, the asymmetric polyacrylonitrile ultrafiltration membrane with a BSA rejection rate of 96.5% is a porous membrane, and the polyethylene glycol methacrylate (PEO526OHMA) with a strong affinity for aromatic hydrocarbons is a large molecular monomer. The specific preparation process of the composite membrane is as follows: 1) The porous membrane is pre-coated with grafted monomer: after the porous membrane is repeatedly rinsed with deionized water, the degassed monomer concentration is placed in the PEO526OHMA monomer aqueous solution of 0.432mol / L 24h at 35°C to complete the pre-coating of the grafted monomer; 2) Plasma irradiates the porous membrane of the pre-coated grafted monomer to initiate a synchronous irradiation grafting reaction: the pre-coated PEO526OHMA monomer Porous Membrane Insertion figure 1 In the reaction chamber 5 of the device shown, the degassed PEO526OHMA monomer aqueous solution is put into the monomer contain...

Embodiment 2

[0044] Select the same asymmetric polyacrylonitrile ultrafiltration membrane as the porous membrane in Example 1, polyethylene glycol methacrylate (PEO526OHMA) is the macromonomer, and the monomer concentration is 0.108mol / L, precoated at 35°C Covering for 24h, helium as the discharge gas, irradiation power of 125W, irradiation time of 90s, and grafting reaction time of 24h after irradiation. The prepared composite membrane is used for the pervaporation separation of a toluene / n-heptane mixture with a toluene mass fraction of 20% at 80°C, and the permeation flux is 5.6kg / m 2 h, the separation factor is 3.

Embodiment 3

[0046] Select the same asymmetric polyacrylonitrile ultrafiltration membrane as the porous membrane in Example 1, polyethylene glycol methacrylate (PEO526OHMA) is the macromonomer, and the monomer concentration is 0.540mol / L, precoated at 35°C Covering for 24h, helium as the discharge gas, irradiation power of 125W, irradiation time of 90s, and grafting reaction time of 24h after irradiation. The prepared composite membrane is used for the separation of toluene / n-heptane mixture with a mass fraction of toluene of 20% at 80°C, and the permeation flux is 2.0kg / m 2 h, the separation coefficient is 6.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com