Cooperative treatment method for waste incineration fly ash and printing and dyeing waste liquid

A technology of waste incineration fly ash and co-processing, applied in textile industry wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high bulk density, low strength of sintered ceramsite, etc. The effect of increasing barrel pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Effect of Voltage Gradient on Purification of Printing and Dyeing Waste Liquid and Properties of Prepared Ceramsite

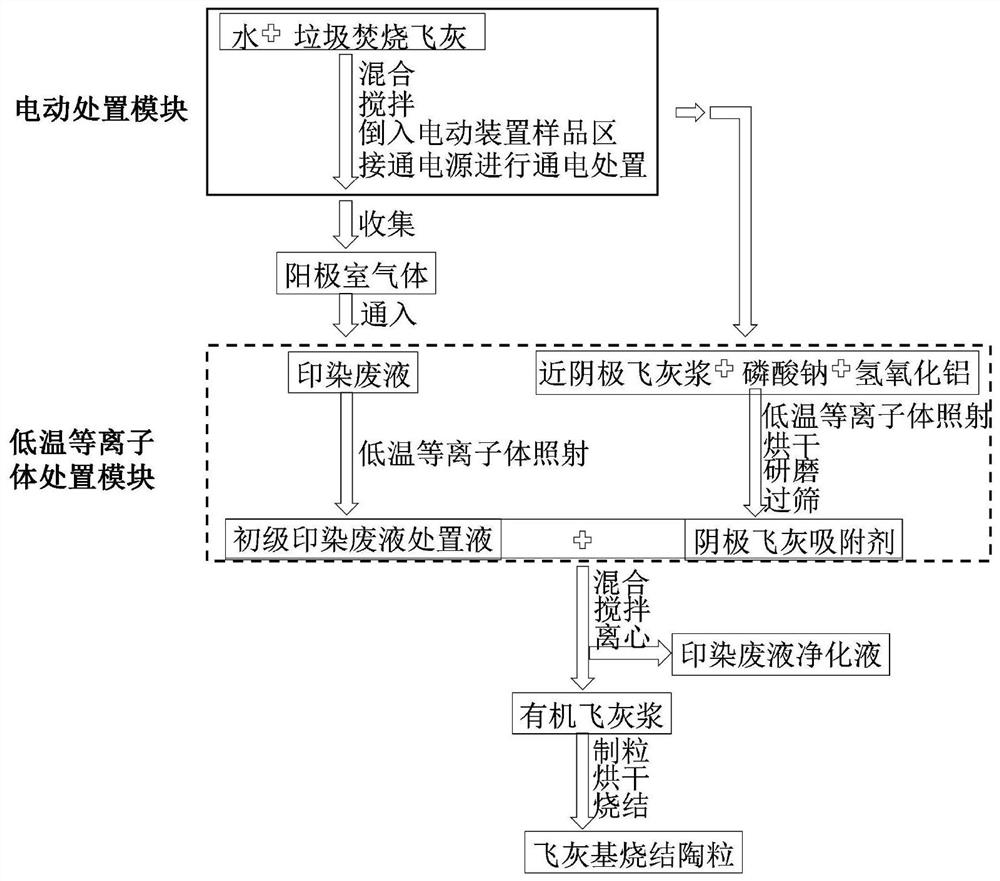

[0023] Co-processing of waste incineration fly ash and printing and dyeing waste liquid: mix water and waste incineration fly ash according to the liquid-solid ratio of water and waste incineration fly ash 0.5:1 (mL:mg), stir for 0.5 hours, and then pour it into the sample area of the electric device , turn on the power supply for energization treatment, where the power supply is a DC constant voltage power supply, and the energization voltage gradient is set to 0.25V / cm, 0.35V / cm, 0.45V / cm, 0.5V / cm, 1.5V / cm, 2.5V / cm cm, 2.6V / cm, 2.8V / cm, 3.0V / cm; collect the gas in the electric anode chamber and pass it into the low-temperature plasma irradiation device as the working atmosphere, turn on the low-temperature plasma irradiation device to treat the printing and dyeing waste liquid for 2 hours, and then Turn off the electric device and the low-temperature...

Embodiment 2

[0037] Effect of mass ratio of sodium phosphate, aluminum hydroxide, and near-cathode fly ash on the purification of printing and dyeing waste liquid and the performance of prepared ceramsite Co-processing of waste incineration fly ash and printing and dyeing waste liquid: according to the liquid-solid ratio of water and domestic waste incineration fly ash 1 :1(mL:mg) Mix water and waste incineration fly ash, stir for 1 hour, then pour into the sample area of the electric device, turn on the power supply for energization treatment, wherein the power supply is a DC constant voltage power supply, and the energization voltage gradient is 2.5V / cm; collect the gas in the electric anode chamber and pass it into the low-temperature plasma irradiation device as the working atmosphere, turn on the low-temperature plasma irradiation device to treat the printing and dyeing waste liquid for 4 hours, then turn off the electric device and low-temperature plasma irradiation device to obtain...

Embodiment 3

[0045] Effects of cathodic fly ash adsorbent and primary printing and dyeing waste disposal liquid-solid-liquid ratio on the purification of printing and dyeing waste liquid and the performance of prepared ceramsite

[0046] Co-processing of waste incineration fly ash and printing and dyeing waste liquid: mix water and waste incineration fly ash according to the liquid-solid ratio of water and domestic waste incineration fly ash 1.5:1 (mL:mg), stir for 1.5 hours, and then pour into the electric device sample In the area, turn on the power supply for energization treatment, wherein the power supply is a DC constant voltage power supply, and the energization voltage gradient is 2.5V / cm; collect the gas in the electric anode chamber and pass it into the low-temperature plasma irradiation device as the working atmosphere, and turn on the low-temperature plasma irradiation device for printing and dyeing. The waste liquid was treated for 6 hours, and then the electric device and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com