Method for doping semiconductor layer, method for manufacturing thin film semiconductor device, and thin film semiconductor device

a semiconductor layer and manufacturing method technology, applied in semiconductor devices, instruments, electrical devices, etc., can solve the problems of high leakage current, low display quality, and high current off, and achieve good reproducibility and low concentration impurity diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

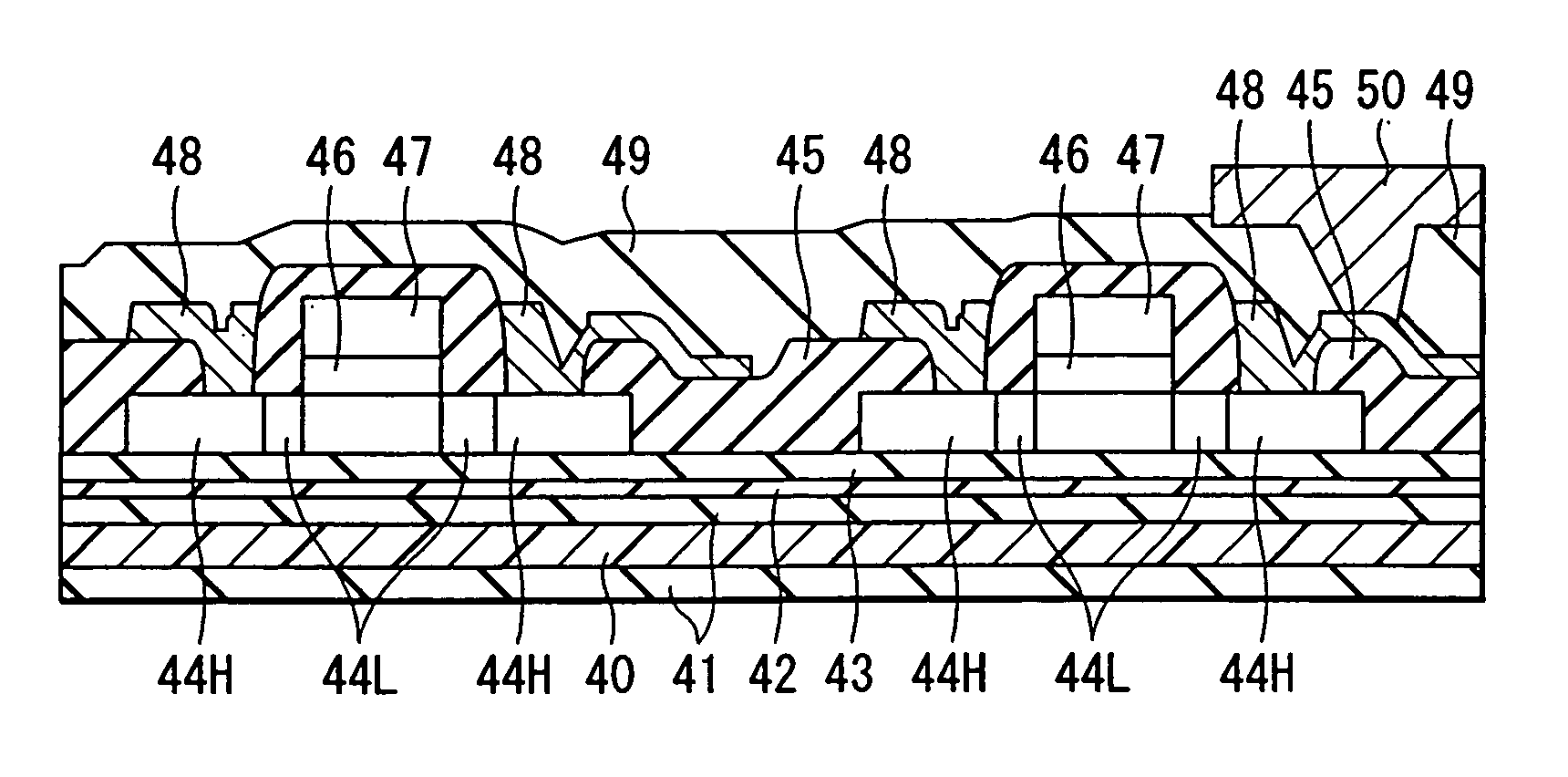

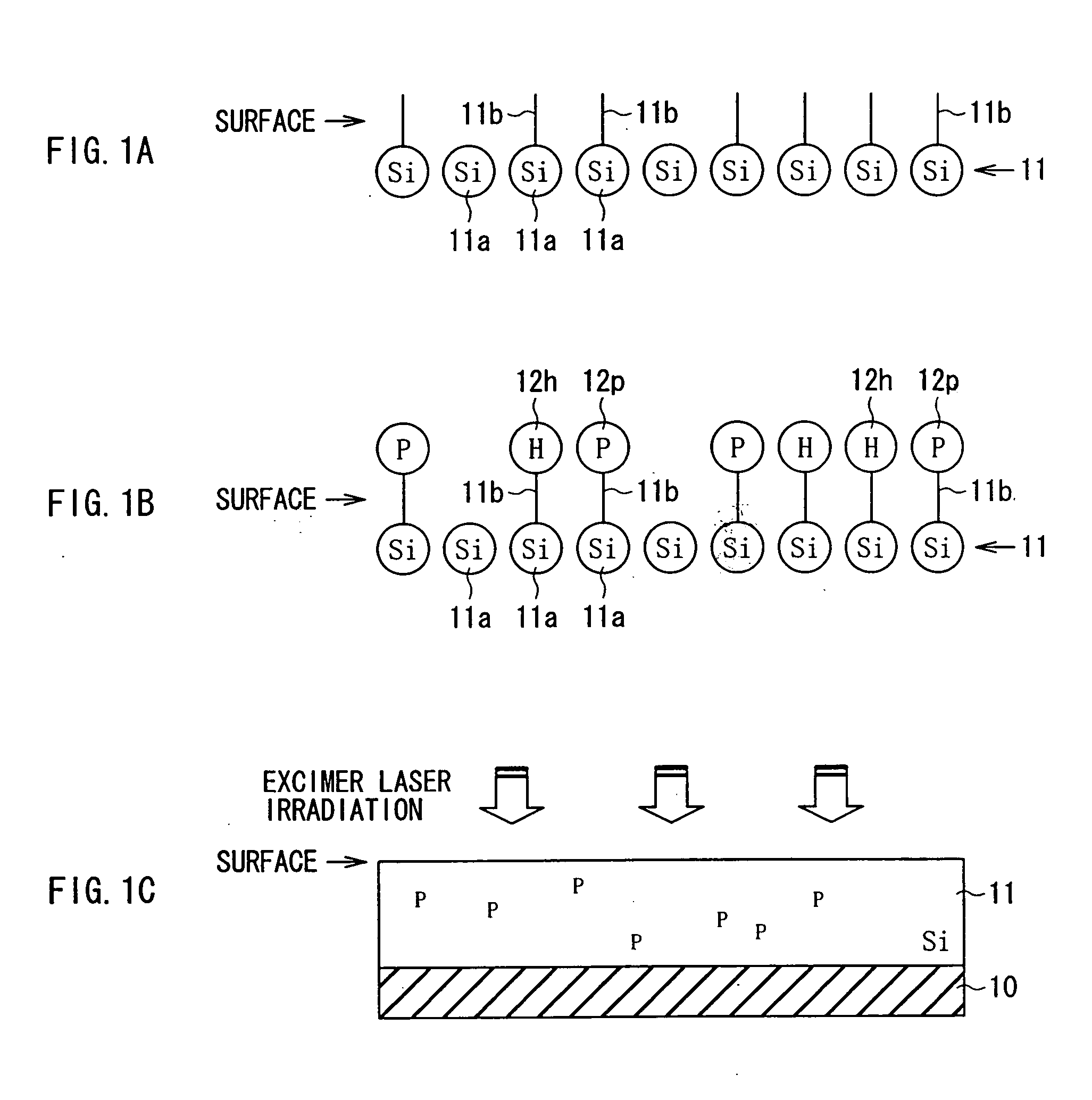

[0035] An embodiment of a method for doping a semiconductor layer according to the invention will be described in detail hereinbelow with reference to FIGS. 1A to 1C. The method for doping the semiconductor layer of the embodiment can form a low concentration impurity diffusion region in a silicon layer formed on a low heat resistant insulating substrate such as plastic or the like with good controllability.

[0036] First, as shown in FIG. 1A, a silicon layer 11 as a semiconductor layer is formed on an insulating substrate 10 (refer to FIG. 1C) and is crystallized by laser beam irradiation of excimer laser at this time. In the surface of the silicon layer 11, a lot of silicon atoms 11a exist in microcrystalline form and dangling bonds 11b exist in some of the silicon atoms 11a.

[0037] Next, as shown in FIG. 1B, dopant gas ion is adsorbed to terminate the dangling bonds 11b on the surface of the silicon layer 11 by plasma of dopant gas without semiconductor deposition gas. The dopant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lengths | aaaaa | aaaaa |

| deformation temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com