Method for improving bioleaching effect of municipal solid waste incineration flying ash

A municipal solid waste and biological leaching technology, which is applied in the field of heavy metal removal effect, can solve the problems affecting the metal dissolution effect, and achieve the effect of improving the heavy metal dissolution rate, high efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

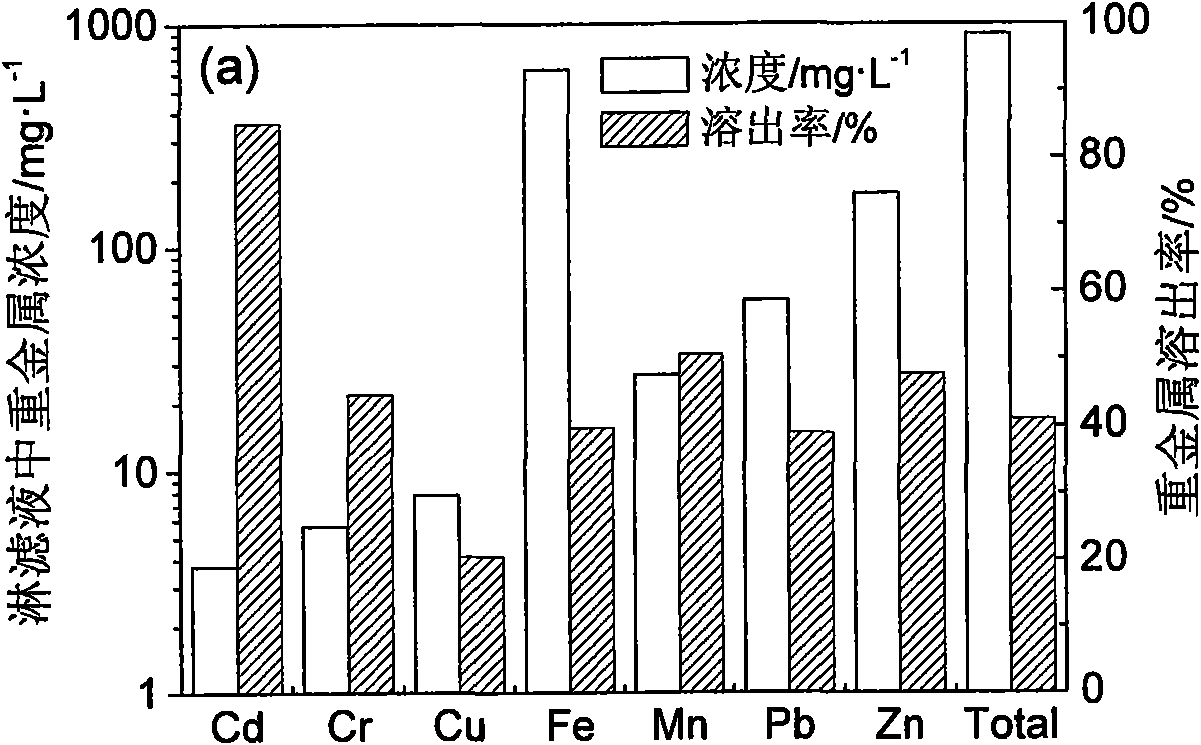

Embodiment 1

[0022] (1) Biological desilication of fly ash using silicate bacteria

[0023] (a) Pick a ring of the activated silicate bacteria SDB6 slant strain and inoculate it into 50 mL of seed culture medium, and incubate at 28° C. and 180 r / min constant temperature shaking for 48 hours. Wherein, the composition of silicate bacteria seed culture medium is: sucrose 5.0g / L, yeast powder 1.0g / L, K 2 HPO 4 2.0g / L, MgSO 4 ·7H 2 O 0.5g / L, CaCO 3 0.1g / L, FeCl 3 ·6H 2 O 0.005g / L, pH 8.0.

[0024] (b) the seed liquid (a) is inserted in the silicate bacteria liquid medium with a volume ratio of 2% (v / v), and the liquid filling amount of the medium is controlled at 20% (v / v) of the culture container, Under the conditions of temperature 30° C. and rotational speed 180 r / min, constant temperature shaking culture was carried out for 3 days. Then, 10 g / L fly ash was added to the Erlenmeyer flask for desiliconization treatment for 5 days. Among them, the composition of silicate bacteria liq...

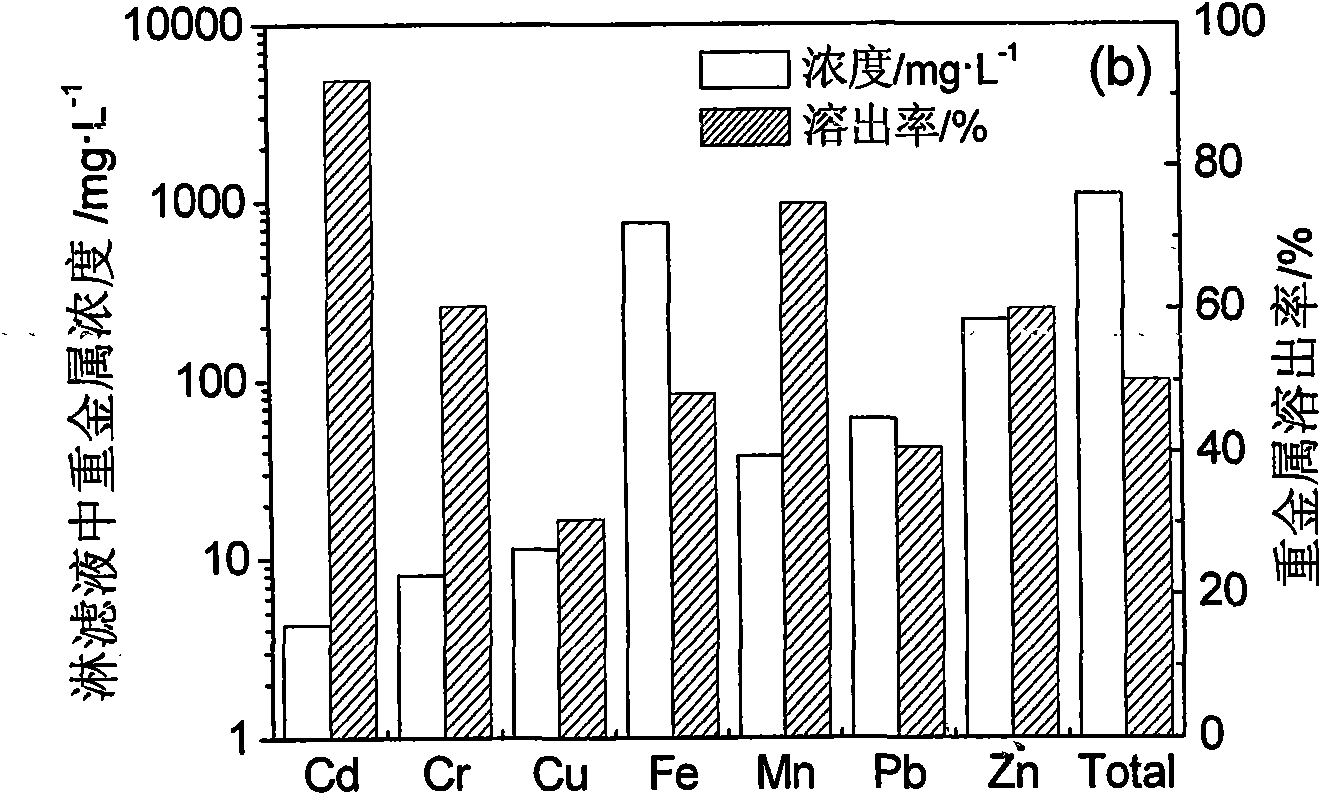

Embodiment 2

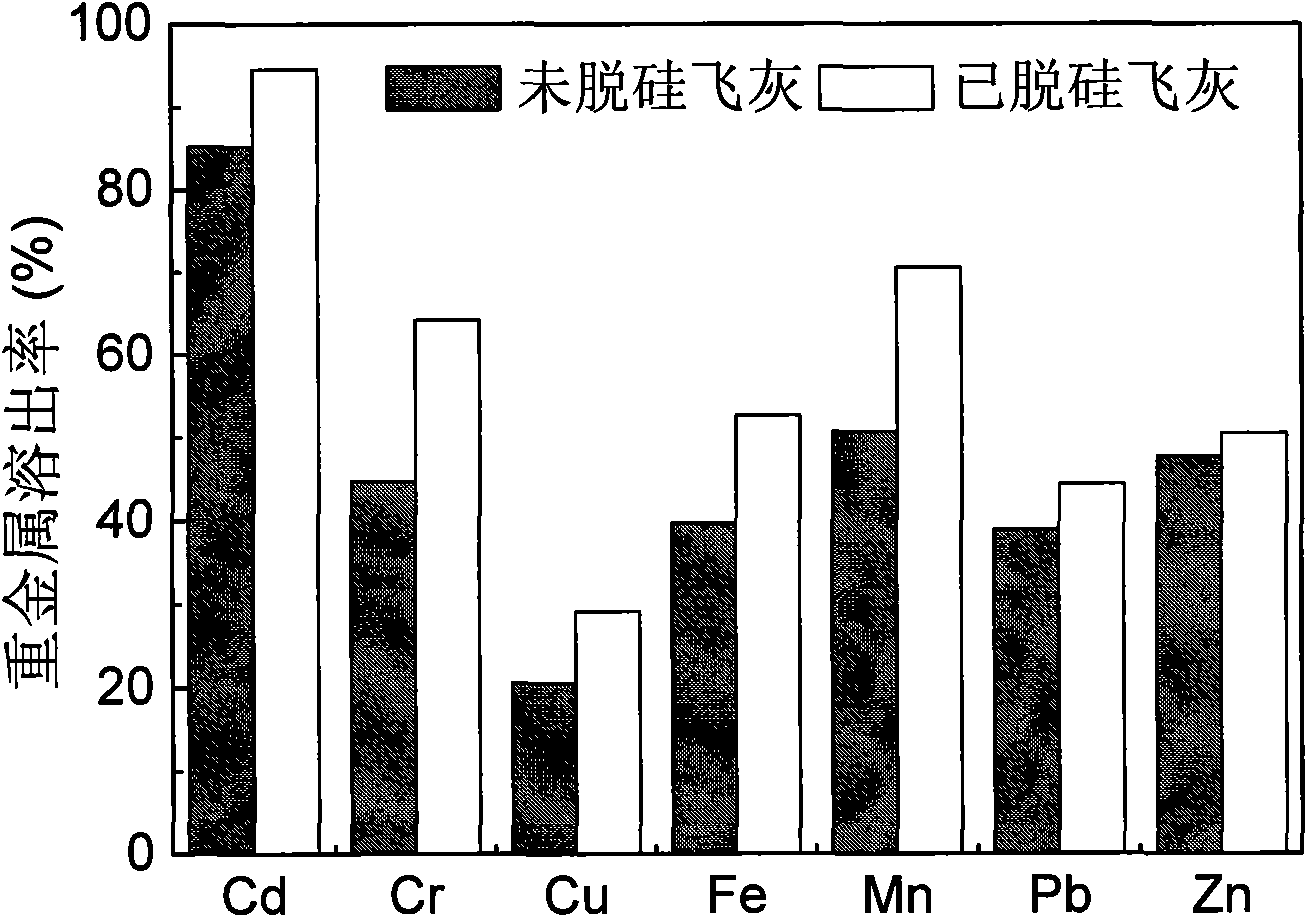

[0030] (a) the steps are the same as in Example 1; (b) the seed liquid (a) is inserted in the silicate bacteria liquid culture medium with a volume ratio of 2% (v / v), and the liquid filling amount of the culture medium is controlled at 20% (v / v) of the container was cultured with constant temperature shaking at a temperature of 25° C. and a rotation speed of 150 r / min for 5 days. Then, 20 g / L fly ash was added to the Erlenmeyer flask for desiliconization for 5 days. Wherein, the composition of the silicate bacteria liquid medium is the same as that in Example 1, and the pH value of the medium is adjusted to 7.5. (c) and (d) steps are all identical with embodiment 1. image 3 Indicates the leaching rate of heavy metals in the bioleachate of non-desiliconized fly ash and desiliconized fly ash. It can be seen that the bioleaching effect of heavy metals in desiliconized fly ash is significantly higher than that of non-desiliconized fly ash.

[0031] Table 1 Non-desiliconized fly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com