Municipal solid waste incineration fly ash curing method

A technology of domestic waste incineration and waste incineration fly ash, which is applied in the direction of solid waste removal, etc., can solve the problems of secondary pollution, high energy and resource consumption, and high cost, and achieve the effect of reducing solidification costs and realizing waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

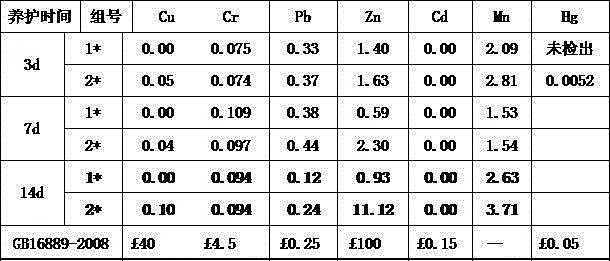

[0014] The domestic waste incineration fly ash solidification method of the present invention is to mix the waste incineration fly ash, strontium carbonate waste residue, potassium carbonate and cement in parts by mass of 40-50: 25-38: 3-6: 15-25, and then add an appropriate amount of pure water After stirring evenly, fill it into the forming model, squeeze and fill it, and then place it in the air for 24 hours before demoulding to obtain a solidified body; the solidified body can be cured to obtain a solidified body that can be directly buried. The time is not less than 14d.

[0015] Strontium slag is the product of roasting at 100-1200°, which cannot make the strontium slag into a molten state, so the strength of strontium carbonate waste slag is not high. However, in the presence of alkaline additives and water, it can produce a gel substance like cement hydration, forming a high-strength and low-permeability cement matrix. Add appropriate amount of potassium carbonate to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com