Novel synthetic heavy metal chelating agent

A chelating agent and heavy metal ion technology, which is applied in the field of new synthetic heavy metal chelating agents, can solve the problems of large energy consumption, high processing cost, and unsatisfactory fixation effect of heavy metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

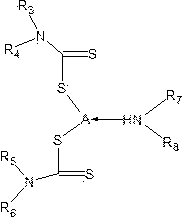

Image

Examples

Embodiment 1

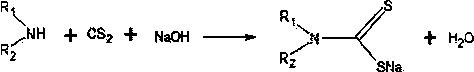

[0032] Example 1: Synthesis of sodium polyethyleneiminoxanthate (PEX).

[0033] (1) Weigh 77.5g of 50% PEI aqueous solution (1.02mol), add 110ml of H 2 0 diluted evenly and transferred to a three-neck flask. with 100ml H 2 0 Dissolve 40.82g (1mol) NaOH (wt=98%), then mix with PEI solution, and keep the reaction temperature at 25-34°C.

[0034] (2) While stirring, add 83.6g (1.1mol) CS dropwise 2, The dropwise addition took about 2 hours.

[0035] (3) Then keep the temperature at 26~32℃ and react for 2.5~3.5 hours. An orange-red jelly-like solid is obtained, which is the product.

[0036] (4) Precipitate the obtained product in acetone medium, and dry it in vacuum at 40~45°C to form a film.

Embodiment 2

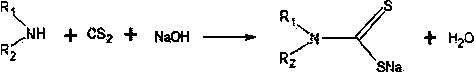

[0037] Example 2: Synthesis of the agent mercaptoacetylpolyethylene (MAPEI).

[0038] Take a small amount of polyethyleneimine solution in a four-necked flask, then add some catalyst and thioglycolic acid to the flask, and install a thermometer, stirrer, condenser and dropping funnel in the flask at the same time. Add alkaline solution (NaOH) to adjust the pH of the solution to alkaline, and stir and react at room temperature for 11-13 hours. After the reaction is finished, acetone is added to the product, and the product is obtained after filtering, washing and vacuum drying.

Embodiment 3

[0039] Example 3: Curing ability of modified polyene polyamines to Cr ions.

[0040] Take 500mL deionized water, add it to the beaker, and add 788mgCrCl to the beaker at the same time 3 Purple crystals, stirred for about 5 minutes and left to stand, then transferred the solution to a 1000mL volumetric flask, shaken and then stood still, transferred the liquid in the volumetric flask to a 100mL beaker with a 25mL pipette, and then added a little Modified polyene polyamine solid, and kept stirring, after reacting for about 30min, detect the remaining Cr in the aqueous solution 3+ ions, the results show that Cr in the solution 3+ The ion concentration was 21.69 mg / kg. It can be seen that the modified polyene polyamine heavy metal ion chelating agent has a significant effect on Cr 3+ The curing rate of ions is 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com