Method for processing organic chloride and heavy metal polluted bed mud

A technology of organic chloride and polluted bottom sludge, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve high melting temperature, high investment and operating costs, fly ash and smoke Harmlessly deal with system complexity and other issues, to achieve the effect of cutting manufacturing prices, reducing operating costs, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

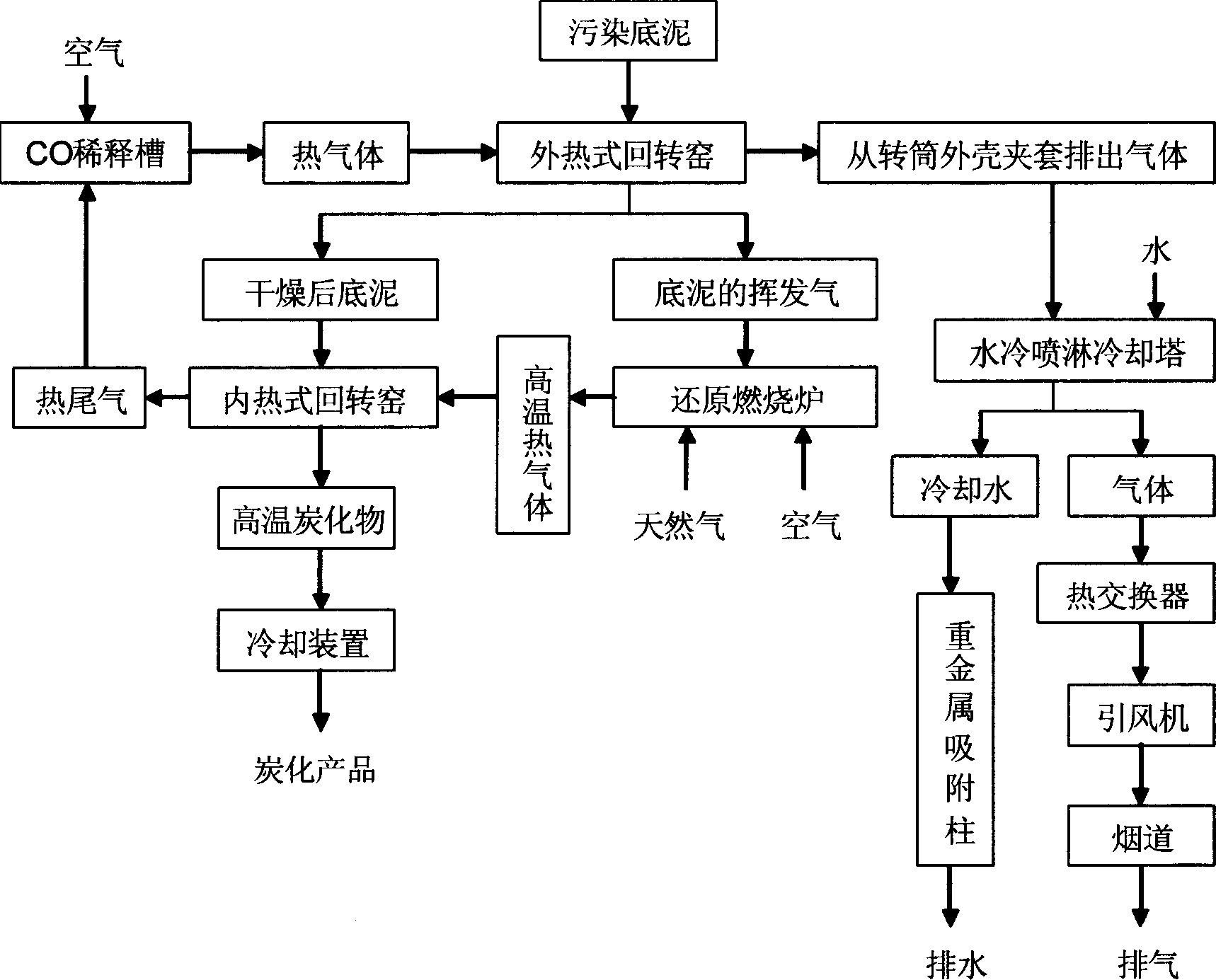

Method used

Image

Examples

Embodiment

[0036] 1. Implementation conditions:

[0037] (1) Sludge source: Suzhou River bottom sludge in Shanghai, China

[0038] (2) Composition of sludge:

[0039] Heavy metals (mg kg -1 )

[0040] "CODcr" refers to chemical oxygen demand (chemical oxygen demand), the total amount of dioxins represents the sum of three organic chlorides (PCDFs+PCDDs+PCBs), and the concentration is expressed in TEQ (Toxic Equivalency Quantity).

[0041] (3) Bottom mud moisture content: 50%;

[0042] (4) Air excess coefficient: 0.9, natural gas burns in the combustion furnace anoxic, and the internal heating rotary kiln is a reducing atmosphere;

[0043] (5) The flame temperature of the reduction combustion furnace anoxic combustion is 1150°C;

[0044] (6) The indirect heating gas outlet temperature of the preheated and dried externally heated rotary kiln is 400°C, and the residence time of the bottom sludge in the externally heated rotary kiln is 60min;

[0045] (7) After drying, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com