Cement kiln calcining resource method for domestic waste burning fly ash

A domestic waste incineration and cement kiln technology, applied in cement production, etc., can solve the problems of high chlorine salt content in fly ash, difficult to use, and fly ash disposal, and achieve the effect of simple and practical technology, cost reduction, and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

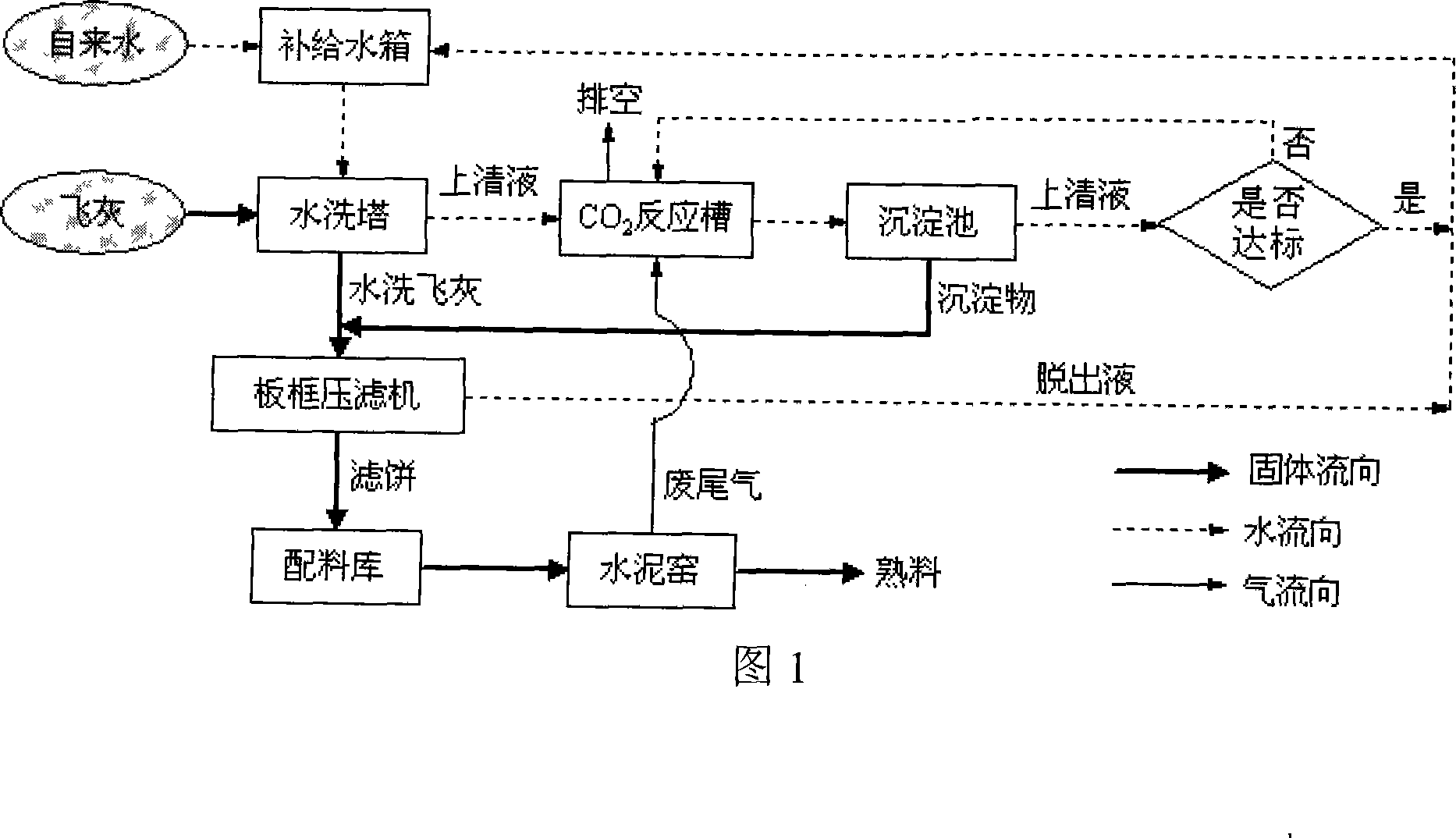

Method used

Image

Examples

Embodiment 1

[0025] The incineration fly ash of a municipal solid waste incineration plant has a water content of 1.93%, a Cl element content of 17.96%, a Zn element content of 0.54%, a Pb element content of 0.23%, a Sn element content of 0.12%, and a Cu element content of 0.09%, Cr element content is 0.09%.

[0026] Mix water and incineration fly ash in water washing equipment according to the weight ratio of water: ash = 5:1, stir for 30 minutes, let stand for 2 hours, and then extract the supernatant to CO 2 In the reaction tank, the exhaust gas of the cement kiln is passed to control the CO 2 The ventilation volume is 1.4L (CO 2 ) / L (supernatant). The chlorine content of the washed fly ash was reduced from 17.96% to about 1% after plate and frame pressure filtration, and the heavy metal content and pH value of the supernatant reached the first-class standard for comprehensive sewage discharge after carbonation. After the washed fly ash and carbonic acid precipitate are dehydrated, t...

Embodiment 2

[0028] The incineration fly ash of a municipal solid waste incineration plant has a water content of 2.20%, a Cl element content of 23.11%, a Zn element content of 0.62%, a Pb element content of 0.39%, a Sn element content of 0.11%, and a Cu element content of 0.11%, Cr element content is 0.07%.

[0029] Mix water and incineration fly ash in water washing equipment according to the weight ratio of water: ash = 10:1, stir for 15 minutes, let stand for 2 hours, and then extract the supernatant to CO 2 In the reaction tank, the exhaust gas of the cement kiln is passed to control the CO 2 The ventilation volume is 2.0L (CO 2 ) / L (supernatant). The chlorine content of the washed fly ash was reduced from 23.1% to about 1.1% after plate and frame pressure filtration, and the heavy metal content and pH value of the supernatant reached the first-class standard for comprehensive sewage discharge after carbonation. The washed fly ash and carbonic acid precipitate are dehydrated and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com