Four-section type steam air preheater drainage system

An air preheater, four-stage technology, applied in the field of four-stage steam air preheater drainage system, can solve the problems of deaerator boiling, unable to maintain the pressure inside the heat exchanger tube stably, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

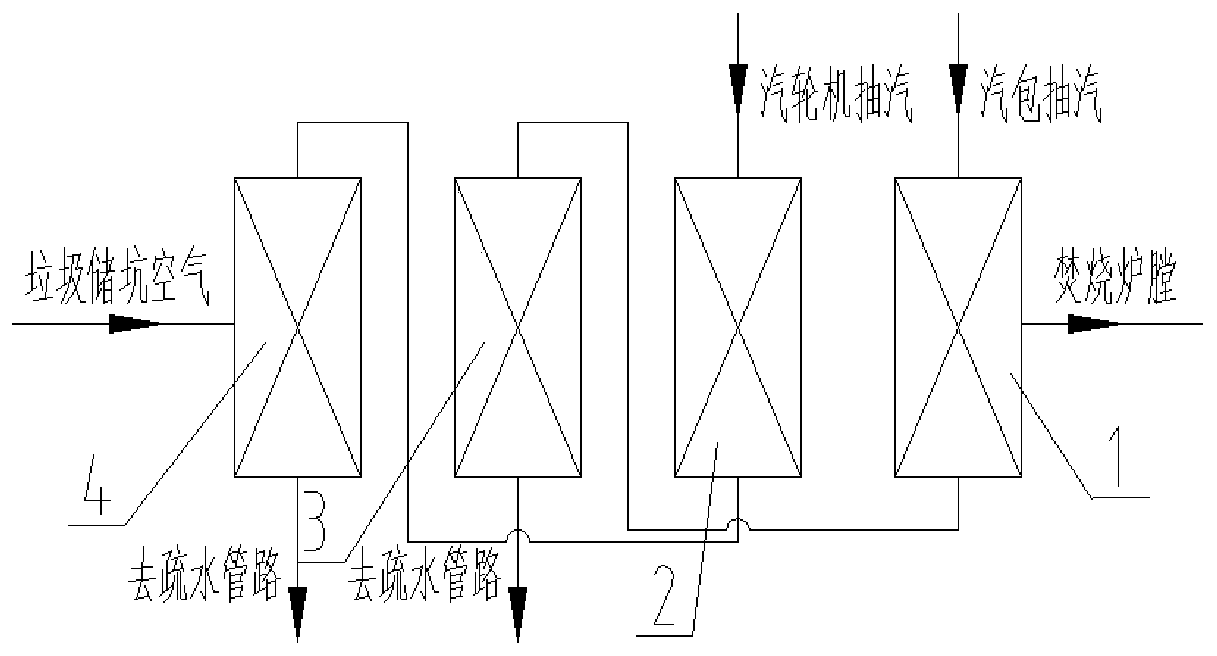

[0014] exist figure 1 In the four-stage steam air preheater, the low-pressure subcooling section heat exchanger (4), the high-pressure subcooling section heat exchanger (3), the low-pressure condensing section heat exchanger (2) and the high-pressure condensing section are arranged in sequence according to the air flow direction heat exchanger (1). The extracted steam from the steam drum enters the heat exchanger (1) in the high-pressure condensing section for heat exchange, then enters the heat exchanger (3) in the high-pressure subcooling section, and finally enters the drain pipeline. The extracted steam of the steam turbine passes through the heat exchanger (2) in the low-pressure condensing section for heat exchange, then enters the heat exchanger (4) in the low-pressure subcooling section, and finally enters the drain pipeline.

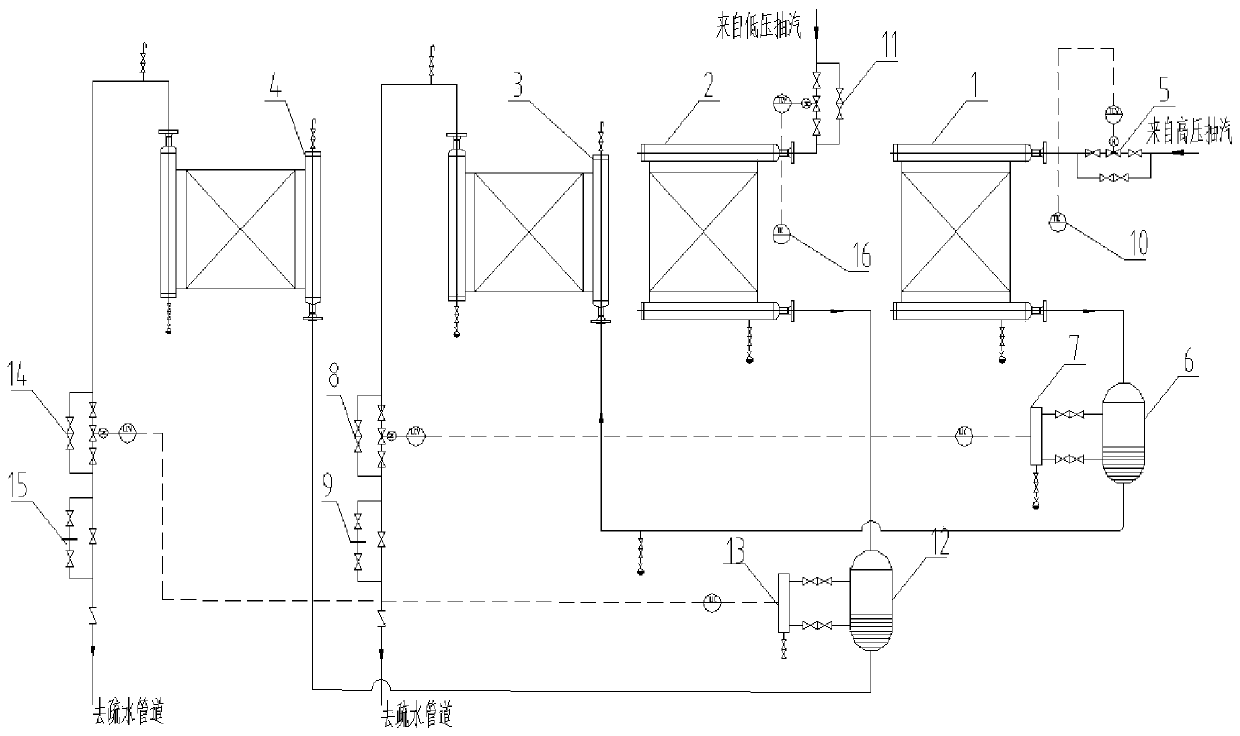

[0015] exist figure 2 Among them, the high-pressure steam extraction regulating valve (5) feeds back the temperature signal through the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com