Control method of burning process of garbage incinerator

A waste incinerator and control method technology, applied in the field of intelligent control of the incineration process of a grate type waste incinerator, can solve problems such as violent fluctuations in furnace temperature, and achieve the effects of improving system resistance parameters, stabilizing combustion, and enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

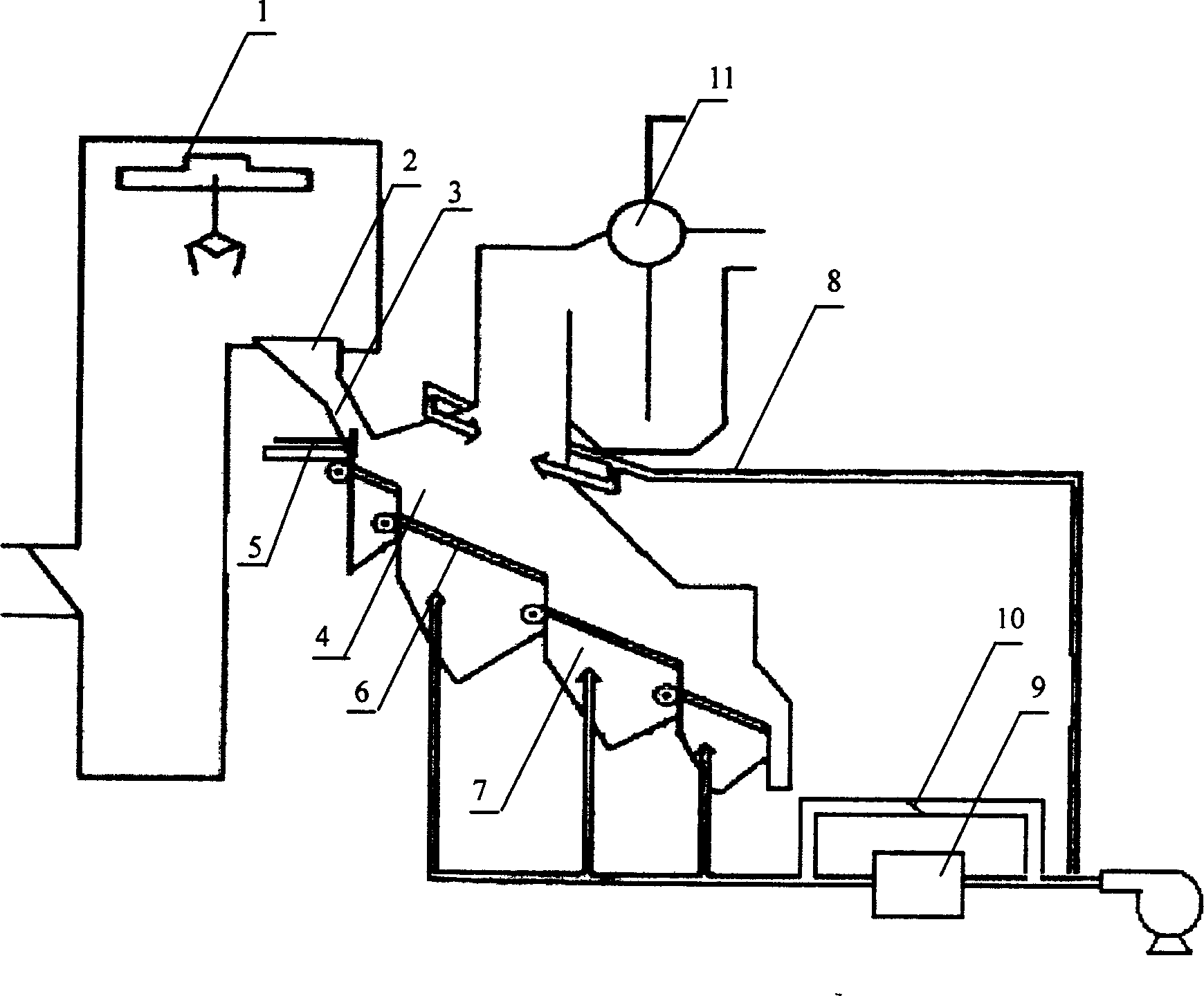

[0022] The basic technological process of waste incineration is as follows: municipal solid waste is collected by the environmental sanitation department and transported to the waste incineration power station, stored in the waste storage pool, then grabbed by the waste crane 1, enters the well 3 from the hopper 2, and fills the hopper 2 with the material. The well 3 closes the furnace chamber 4 . Use hydraulic feeder 5 according to combustion control instruction and rubbish is added in the stove by the speed of setting. The rubbish burns on the fire grate 6 moving in the furnace. During the incineration process, the primary air 7 is blown in from the air chamber 7 below the fire grate, passes through the garbage layer, and reacts with the garbage at the same time to promote the burning of the garbage. The secondary air is blown in by the air pipe 8 above the fire grate, and the main effect of the secondary air is to impel volatile gas and unburned rubbish on the material bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com