Steel excellent in resistance to sulfuric acid dew point corrosion and preheater for air

An air preheater and sulfuric acid-resistant technology, applied in the field of steel, can solve the problems of inability to exert corrosion resistance and incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

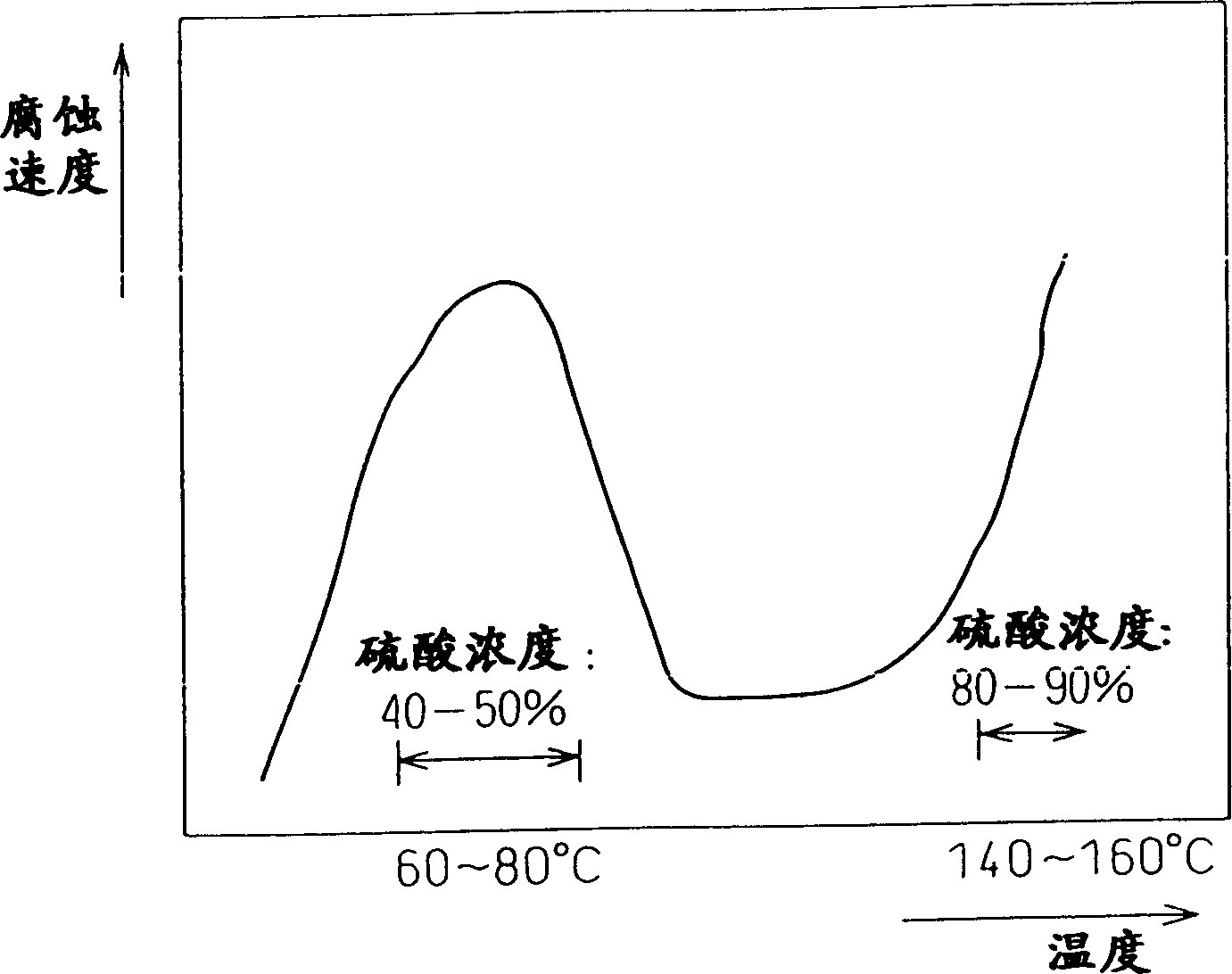

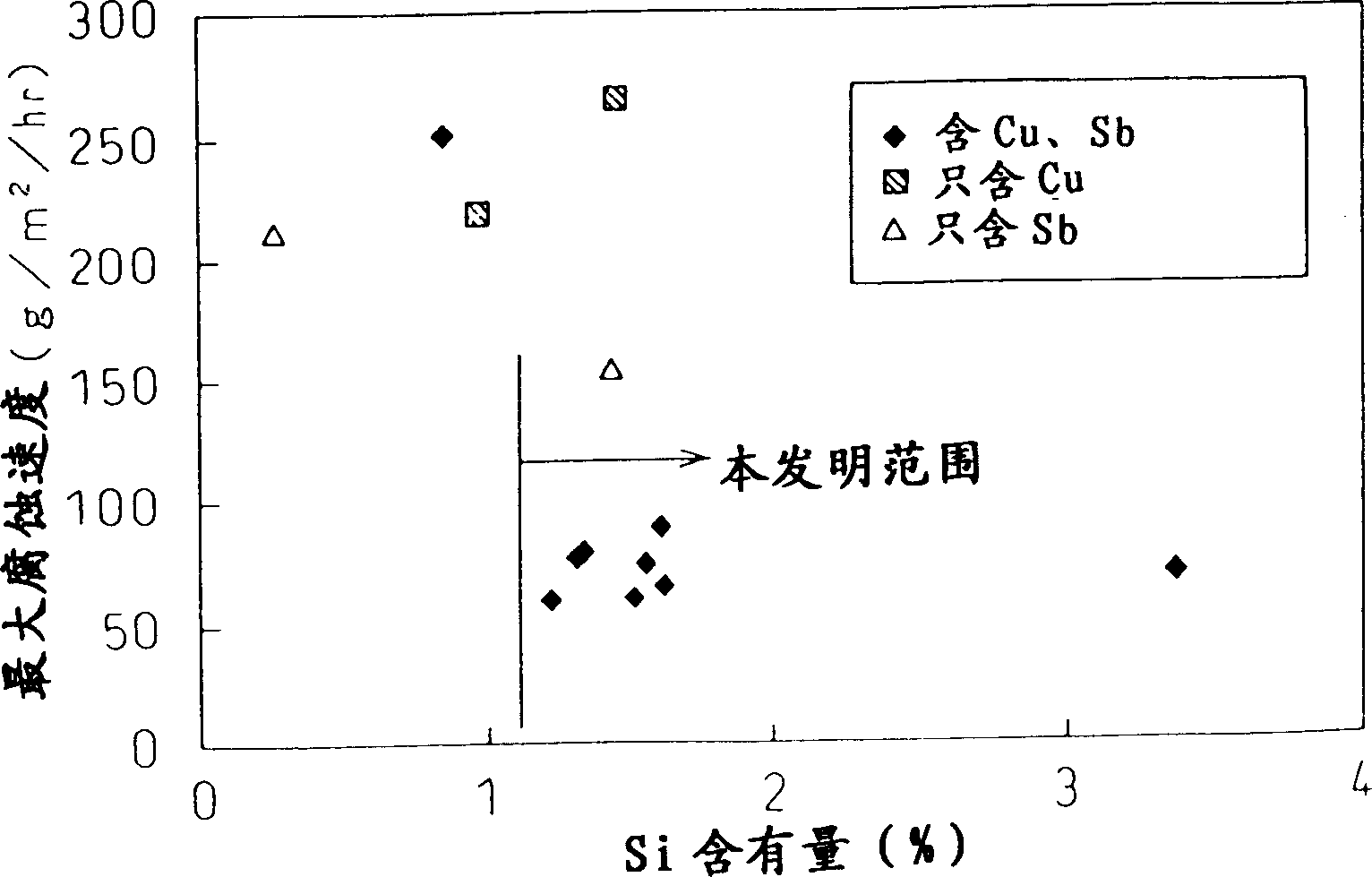

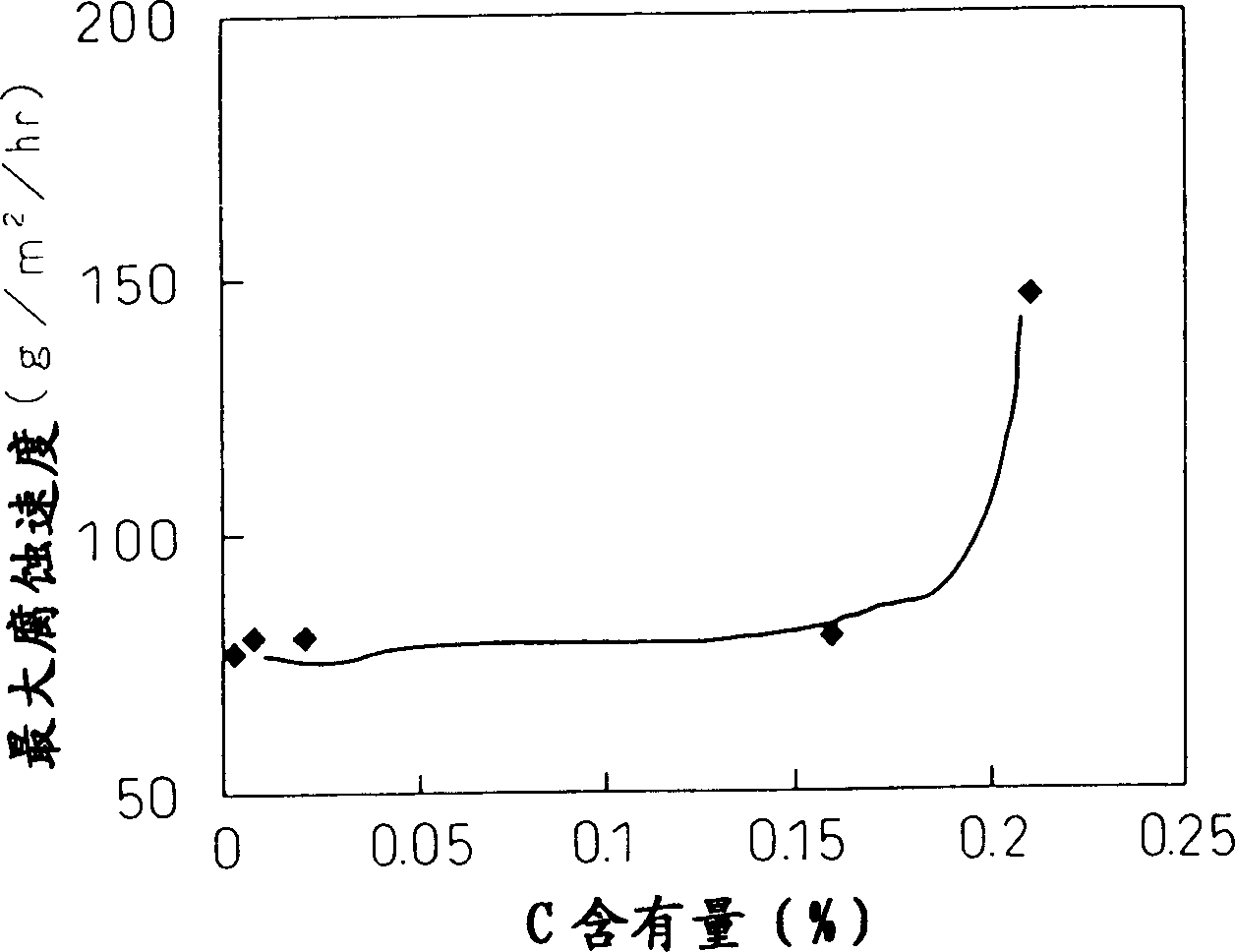

[0042] Melt the steel with the chemical composition shown in Table 1 in a vacuum melting furnace, cast it into a 50kg ingot, and then hot roll it into a plate with a thickness of 12mm. Use rectangular test pieces of t3, 20, and 40mm in size to carry out sulfuric acid corrosion test . As the conditions representing the low-temperature region and high-temperature region under sulfuric acid dew point corrosion environment, in (a) 40% sulfuric acid, 60°C, (b) 50% sulfuric acid, 80°C, (c) 80% sulfuric acid, 140°C and (d) ) 90% sulfuric acid, and 160° C., four hours of immersion tests were carried out to obtain the corrosion rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com