High-efficiency incineration power generation system for municipal solid waste

A municipal solid waste, incineration power generation technology, applied in the field of municipal solid waste treatment technology, can solve the problems of energy consumption, large floor area, long processing cycle, etc. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

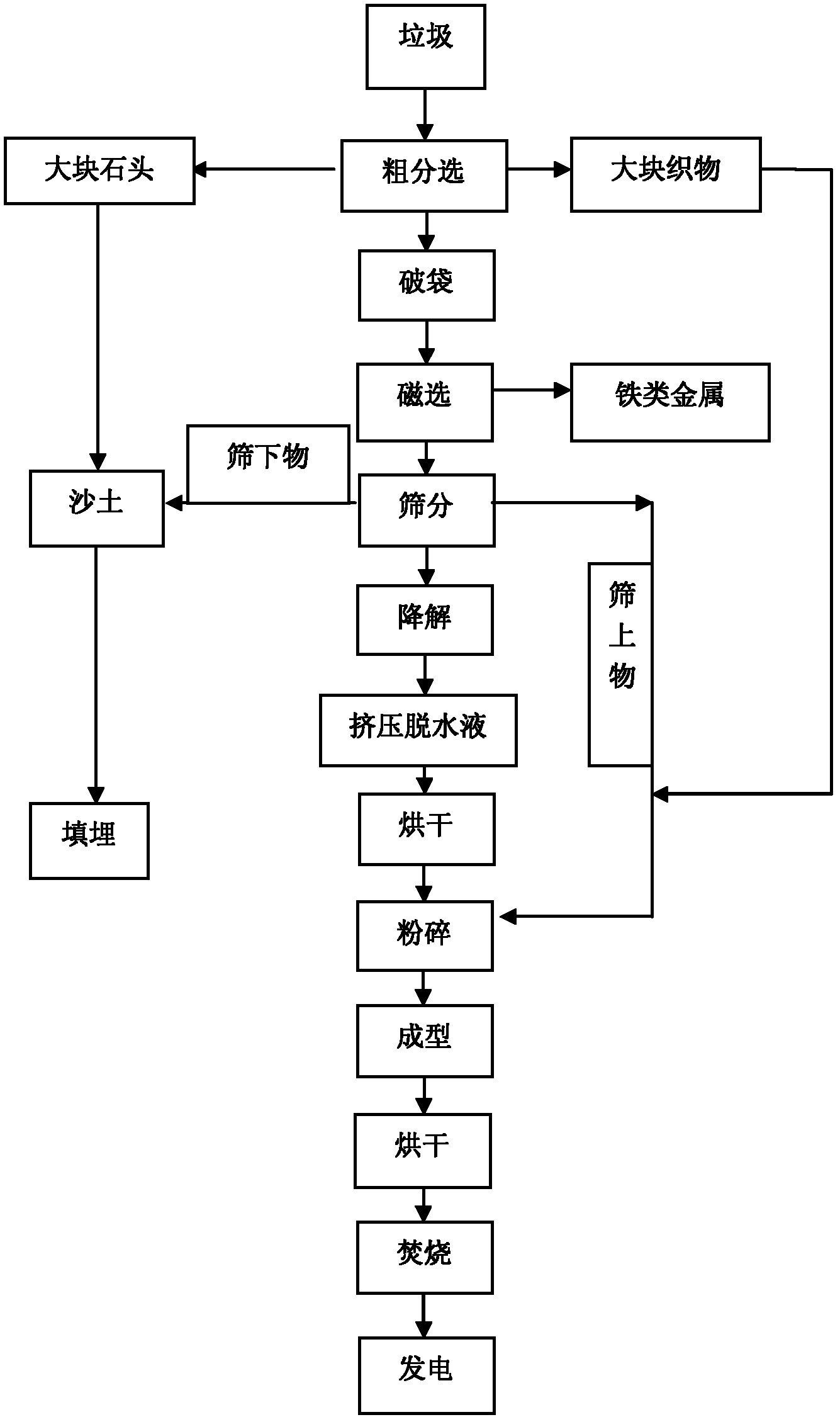

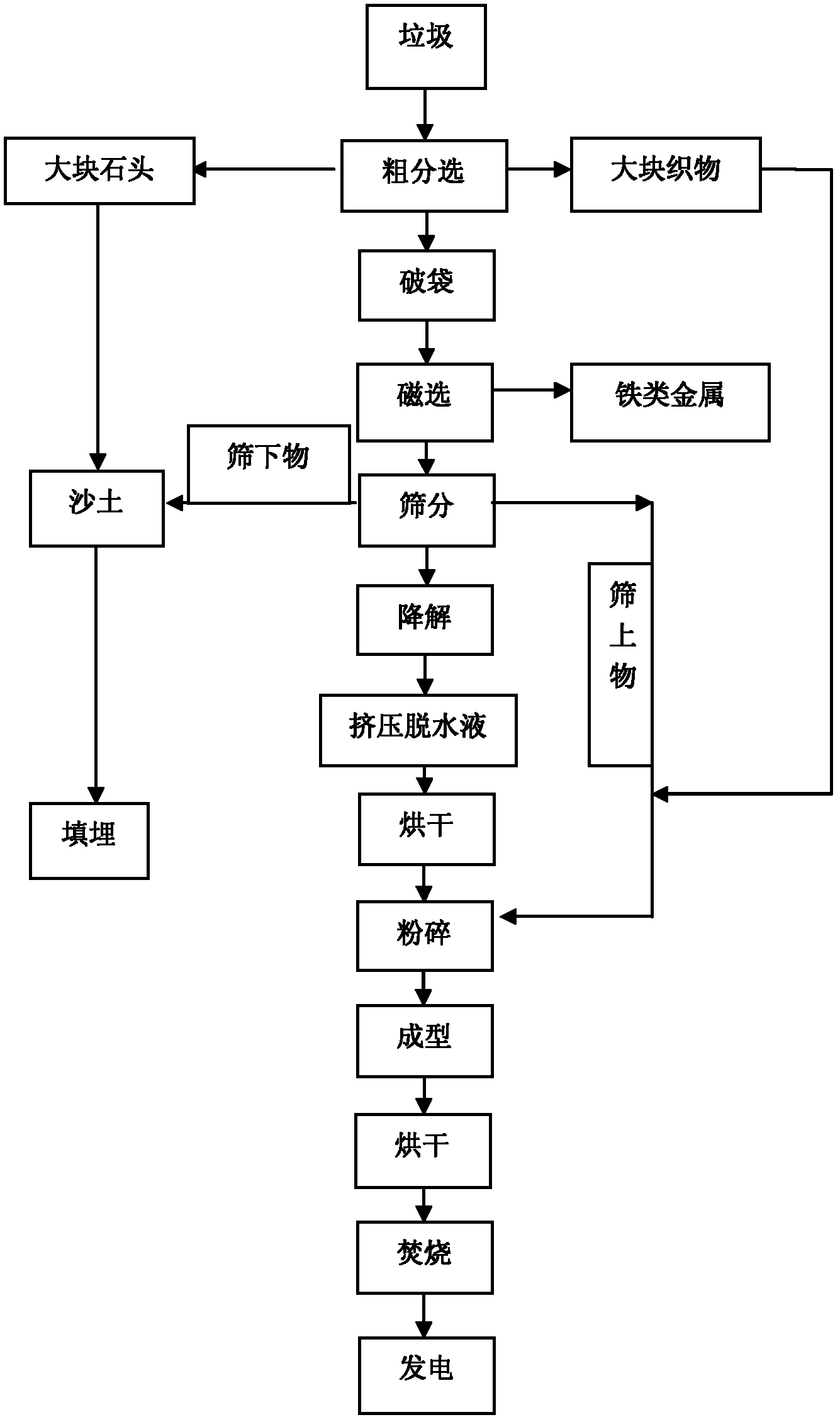

[0010] A high-efficiency incineration power generation system for municipal solid waste, characterized in that it includes the following steps:

[0011] (1) Coarse sorting, sorting out large recyclable materials and other materials;

[0012] (2) Broken bag: break the plastic bag to disperse the material inside the bag to facilitate subsequent processing;

[0013] (3) Magnetic separation, sorting out ferrous metals;

[0014] (4) Sieving: The material under the sieve (sand) is harmlessly landfilled, the material on the sieve is directly crushed, and the material in the sieve is degraded. (

[0015] (5) Degradation, degrade the organic matter in the garbage by steam. When degrading, use a degradation reaction kettle, feed the reactor for 30 minutes, and degrade the reaction kettle with steam at 1.1MPa and 180°C for 90 minutes, and then keep it warm for 30 minutes , and finally drain for 90 minutes.

[0016] After degrading for 1 hour, the structural water of organic matter ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com