Disposition method for municipal solid waste incineration fly ash with microwave hydrothermal method applied

A technology of domestic waste incineration and microwave hydrothermal method, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of restricting large-scale application, secondary pollution, unfavorable large-scale application, etc. Achieve the effect of strong heavy metal adsorption capacity, reduction of process water production, and high resource utilization potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

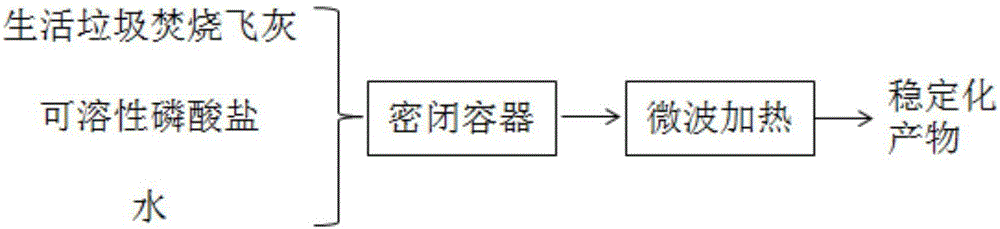

Method used

Image

Examples

Embodiment 1

[0017] Raw materials: waste incineration fly ash 1 to be treated, the original leaching concentration of heavy metals in the fly ash is as follows: Cd 1.948mg / l, Cr 2.213mg / l, Cu 64.787mg / l, Ni 1.521mg / l, Pb 7.851mg / l , Zn 124.5mg / l.

[0018] Treatment method: 1, 1.5 mol of Na per kilogram of waste incineration fly ash to be treated 2 HPO 4 and 2l of water, the three were respectively added into a closed container, heated by microwave at 200°C for 10 minutes, and then liquid-solid separation was carried out to obtain a stabilized product. The leaching concentration of heavy metals in the stabilized product was determined by using the solid waste leaching toxicity leaching method-acetic acid buffer solution method (HJ / T300-2007).

[0019] Measurement results: Cd 0.1447 mg / l, Cr 0.1615 mg / l, Cu 19.58 mg / l, Ni 0.4897 mg / l, Pb 0.0765 mg / l, Zn 34.90 mg / l.

[0020] Conclusion: Under this condition, the solidification rate of heavy metals can reach more than 80% on average, and th...

Embodiment 2

[0022] Raw materials: waste incineration fly ash 2 to be treated, the original leaching concentration of excessive heavy metals in the fly ash is as follows: Cd 0.6025mg / l, Pb 0.4639mg / l.

[0023] Treatment method: 1.0mol of Na per kilogram of waste incineration fly ash to be treated 2 HPO 4 and 2L of water, the three were respectively added into a closed container, heated by microwave at 150°C for 10 minutes, and then liquid-solid separation was carried out to obtain a stabilized product. The leaching concentration of heavy metals in fly ash after disposal was determined by the leaching method of solid waste leaching toxicity-acetic acid buffer solution method (HJ / T300-2007).

[0024] Measurement results: Cd 0.1468mg / l, Pb 0.0645mg / l

[0025] Conclusion: The leaching concentrations of all heavy metal ions meet the landfill requirements. Under this condition, the solidification rates of heavy metals Cd and Pb are 76% and 82%, respectively.

Embodiment 3

[0027] Raw material: the stabilized product obtained in Example 1

[0028] Treatment method: the stabilized products obtained in the examples were mixed with a series of different concentrations of HNO 3 Mix with NaOH mixed solution in an ordinary plastic sealed container, the mixing ratio is to add 20l mixed solution per kilogram of stabilized product, and turn the container containing fly ash and mixed solution at a speed of 30 revolutions per minute for 18 hours, and end Afterwards, solid-liquid separation is carried out, and the pH and heavy metal content of the solution are detected.

[0029] Measurement results: when the pH of the solution after separation is 5-13, almost no heavy metals are detected in the solution.

[0030] Conclusion: The stabilized product has strong acid and alkali resistance, high environmental stability, which is very beneficial for landfill disposal, and also provides high feasibility for resource utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com