Process for preparing gelling material from municipal solid waste incineration fly ash

A technology of domestic waste incineration and waste incineration fly ash, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., to achieve the effect of controlling environmental pollution and protecting water and soil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

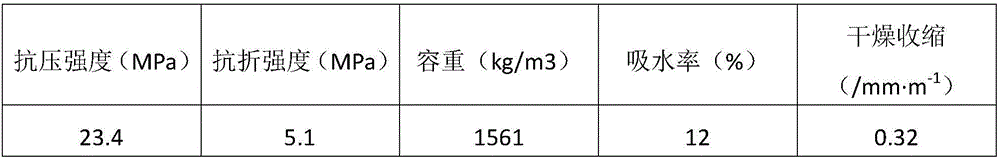

[0022] Take 100 parts of domestic waste incineration fly ash and put them in a container, add 4 parts of sodium hydroxide and 70 parts of water, mix and stir, and complete the pretreatment after reacting at 50°C for 0.5h, and place the pretreated domestic waste incineration fly ash at 105 °C drying for later use. Take 60 parts of domestic waste incineration fly ash, 40 parts of mineral powder, and 4 parts of sodium hydroxide after pretreatment, mix them in a container, add 40 parts of water, stir at 200 rpm for 20 minutes, mix the mixture and inject it into the mold Vibrate at a frequency of 50 times / min for 2 min. The mold sealing film was cured in a constant temperature curing box at 60°C for 12 hours, and then the mold was removed. The removed block was placed in a water curing box at 60°C for 21 days, and then the fly ash-based cementitious material was obtained. The detection index of the test piece in embodiment 1 is shown in the subscript.

[0023] Specimen detection ...

Embodiment 2

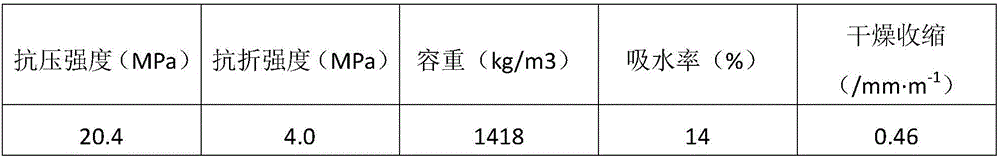

[0026] Take 80 parts of domestic waste incineration fly ash and put them in a container, add 2.5 parts of calcium hydroxide and 50 parts of water, mix and stir, and complete the pretreatment after reacting at 40°C for 1 hour, and place the pretreated domestic waste incineration fly ash at 105°C Dry and set aside. Take 71 parts of domestic waste incineration fly ash after pretreatment, 28 parts of mineral powder, and 8 parts of sodium silicate, put them in a container and mix them evenly, add 51 parts of water, stir at 120 rpm for 25 minutes, pour the mixture into the mold after stirring Vibrate at a frequency of 40 times / min for 3 min. The mold sealing film was placed in a constant temperature curing box at 35°C for 36 hours, and then the mold was removed. The removed block was placed in a water curing box at 30°C for 25 days, and then the fly ash-based cementitious material was obtained. The detection index of the test piece in embodiment 1 is shown in the subscript.

[002...

Embodiment 3

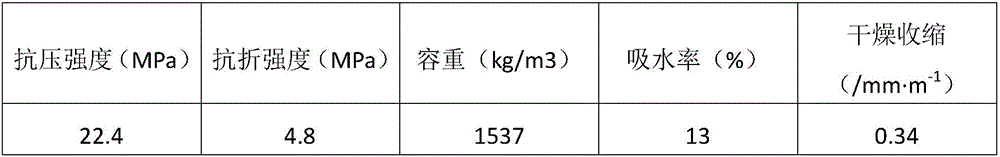

[0030] Take 90 parts of domestic waste incineration fly ash and put them in a container, add 3 parts of potassium hydroxide and 60 parts of water, mix and stir, and complete the pretreatment after reacting at 20°C for 2 hours. Dry and set aside. Take 80 parts of domestic waste incineration fly ash after pretreatment, 20 parts of mineral powder, and 2 parts of potassium hydroxide and mix them in a container, add 60 parts of water, stir at a frequency of 50 rpm for 30 minutes, and inject the mixture into the mold after stirring Vibrate at a frequency of 20 times / min for 6 minutes. The mold sealing film was cured in a constant temperature curing box at 20°C for 48 hours, and then the mold was removed, and the removed blocks were cured in a water curing box at 20°C for 28 days to obtain a fly ash-based cementitious material. The detection index of the test piece in embodiment 1 is shown in the subscript.

[0031] Specimen detection index in the embodiment 1 of table 3

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com