Aluminums strips position and compaction device of hollow glass molecular sieve filling machine

The technology of a pressing device and a molecular sieve is applied in the field of aluminum strip positioning and pressing device of an insulating glass molecular sieve filling machine, and can solve the problems of large horizontal pressing force of the pressing device, affecting the filling speed, and indentation on the surface of the aluminum strip, etc. To achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

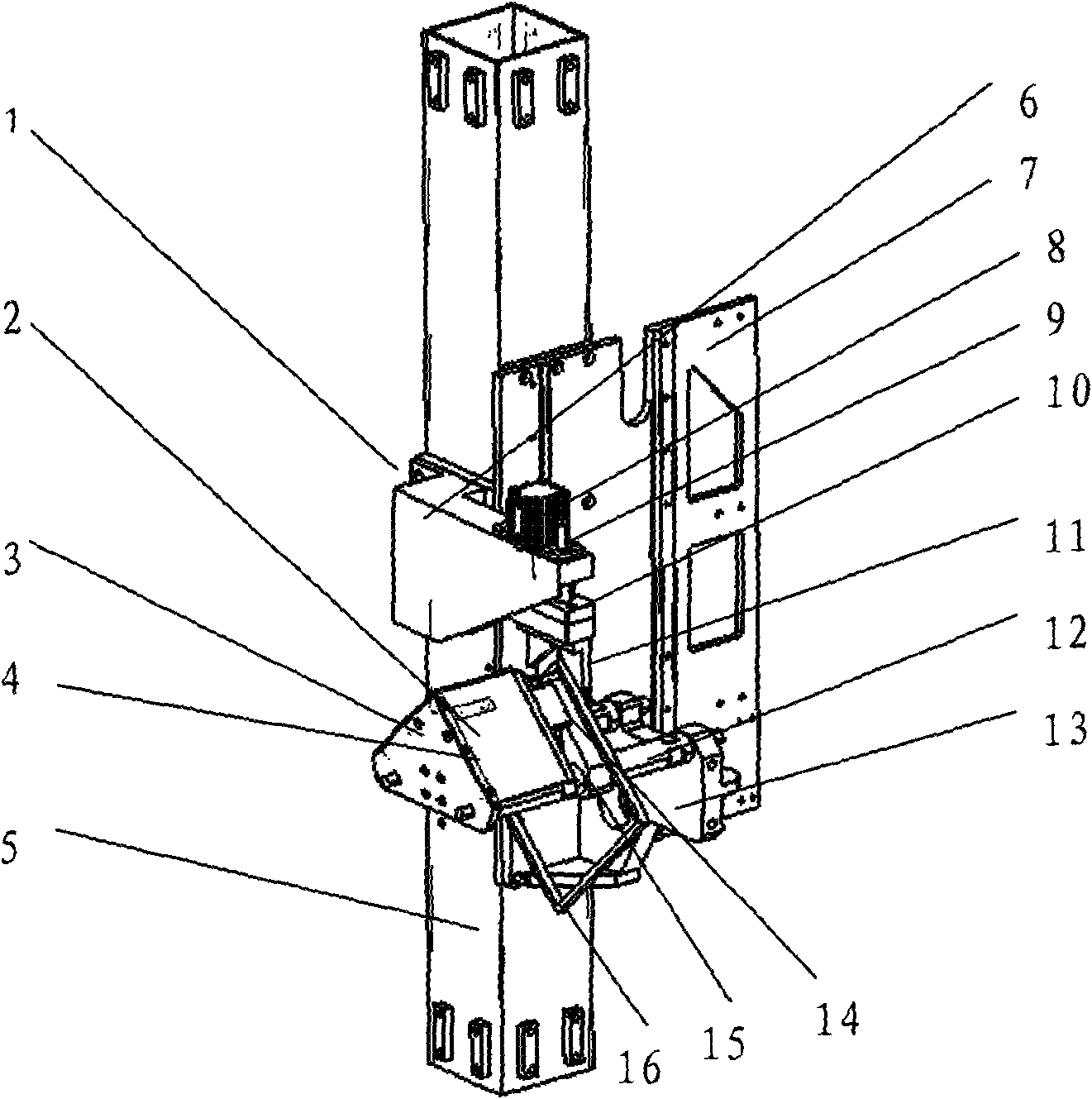

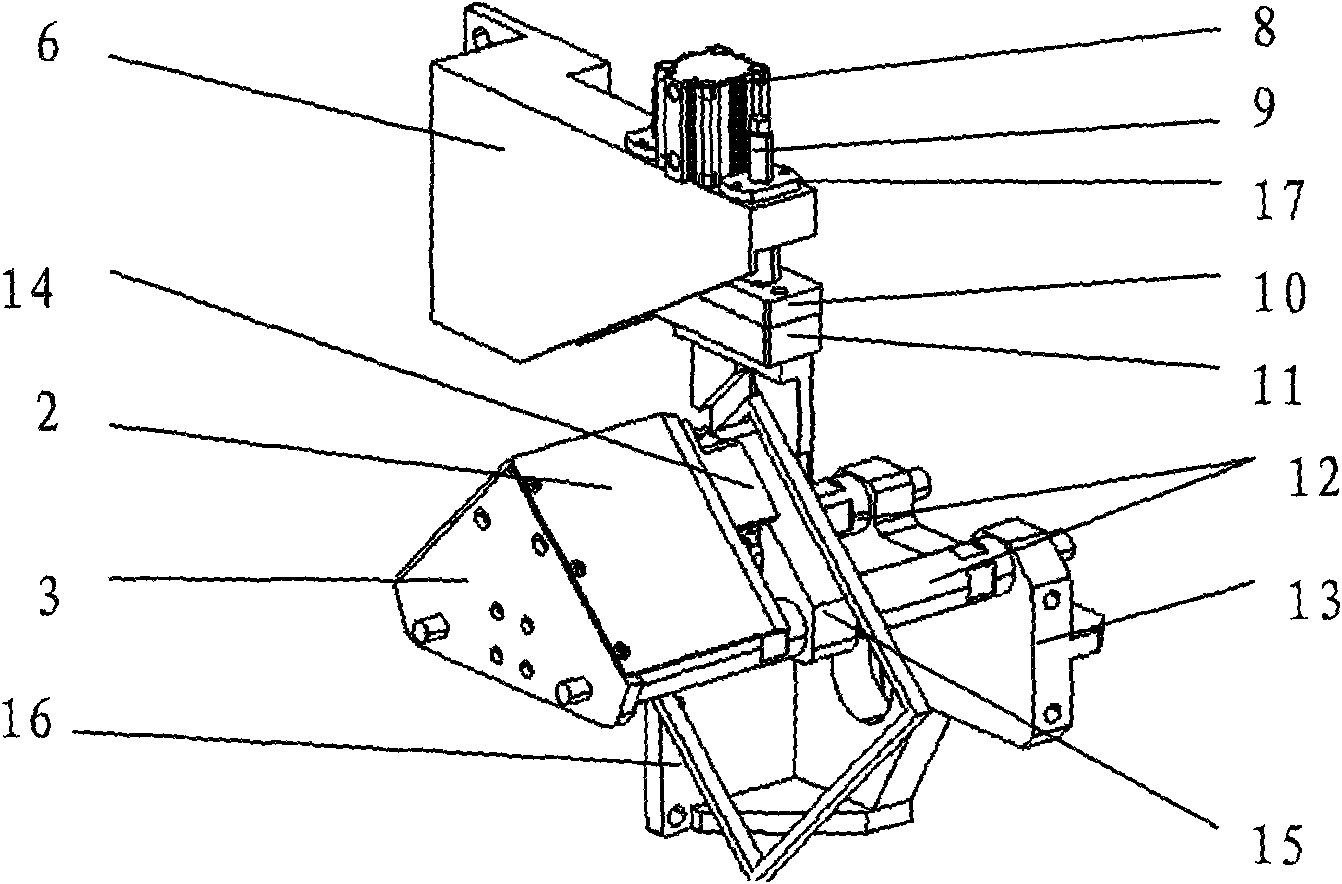

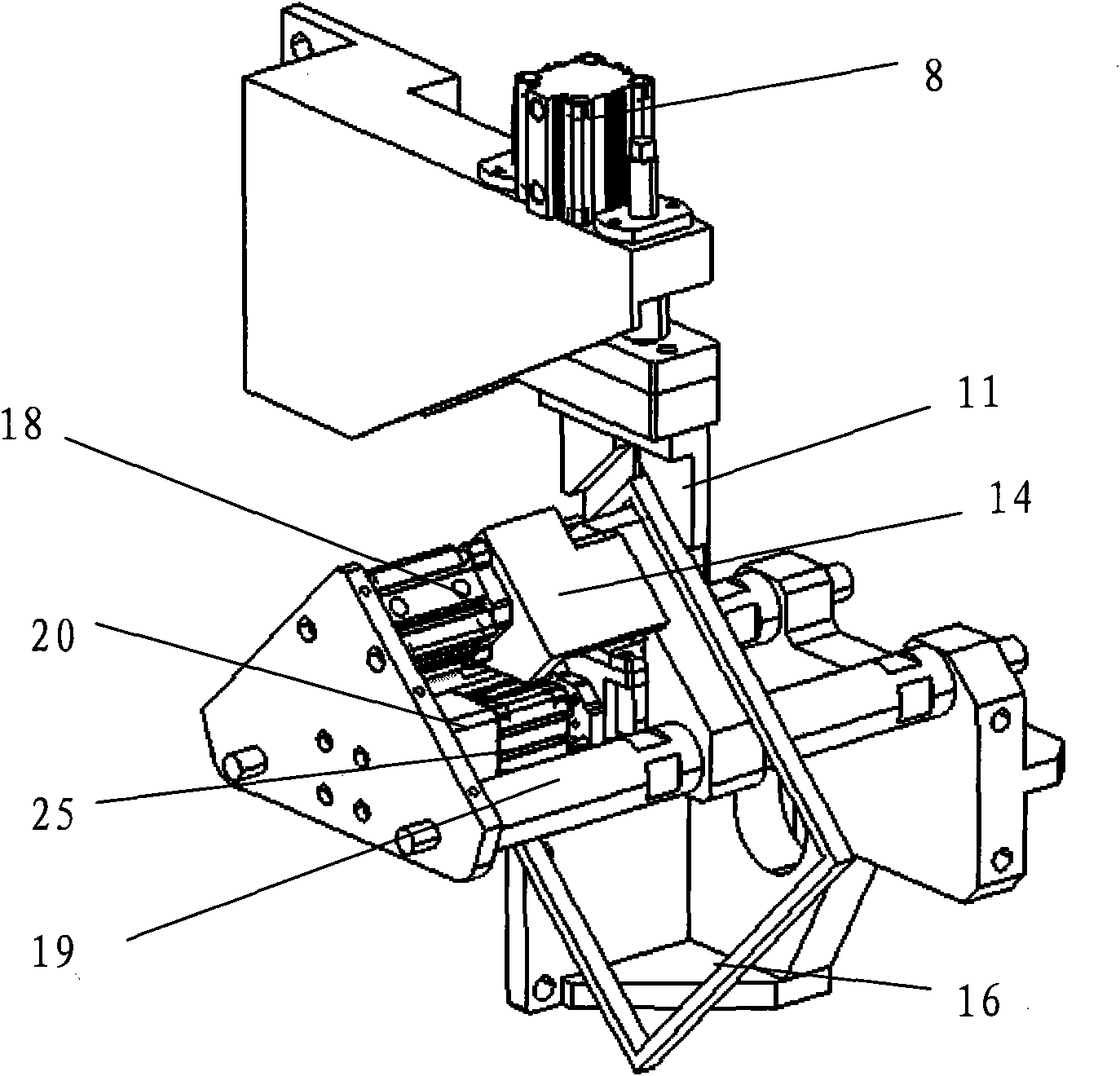

[0036] like Figure 1 to Figure 19 As shown, the aluminum strip positioning and pressing device of the hollow glass molecular sieve filling machine of the present invention is composed of a pressing and positioning assembly, a square tube bracket 5, and a rear panel 7; the pressing and positioning assembly is composed of a horizontal pressing device 4 and a longitudinal pressing device 1, and is connected to the hollow glass molecular sieve filling machine through the square tube bracket 5 and the rear panel 7; the horizontal pressing device 4 is composed of the cylinder cover plate 2, the cylinder fixed connection block 3, the pressing block 14, the pressing seat 15, the transverse Compression guide rod one 12, lateral compression guide rod two 19, lateral positioning plate 22, positioning cylinder 25, positioning cylinder support seat 20, horizontal cylinder support 13 and lateral compression cylinder 18; horizontal cylinder support 13 is fixedly connected On the rear panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com