Spot welding technological method for aluminum alloy workpiece

A process method, aluminum alloy technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of large fluctuation of nugget diameter, large resistivity, easy to produce splash and splash, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

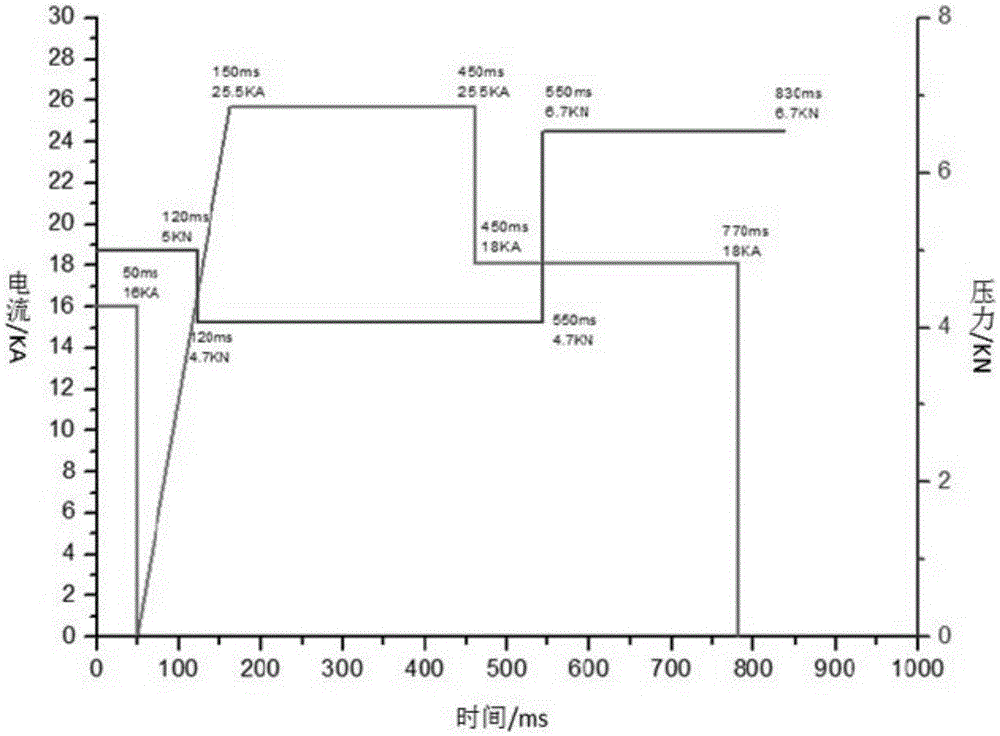

[0016] like figure 1 Shown, the spot welding process method of aluminum alloy workpiece of the present invention comprises following operation method:

[0017] Step 1. Pretreatment of the aluminum alloy workpiece to be spot welded: Since there is an oxide film on the surface of the aluminum alloy workpiece, it is necessary to pretreat the aluminum alloy workpiece:

[0018] First, place the workpiece to be welded in a sodium hydroxide solution with a concentration of 5% to 10% by mass and soak for 30 to 60 seconds for degreasing and rinsing; then place the workpiece to be welded in nitric acid with a concentration of 15% by mass Corrosion in the solution for 2 minutes, in order to slow down the growth rate of the new film and fill the pores of the new film, it can also be purified while corroding. The purification agent is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com