Paddy field stubble burying cultivator

A technology for tilling machines and paddy fields, applied in the field of farmland tilling machines, can solve the problems of increasing the number of round trips, affecting land leveling, and high operating costs, and achieving the effects of improving work efficiency, increasing the number of round trips, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

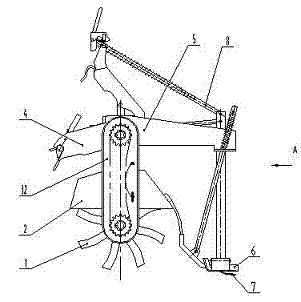

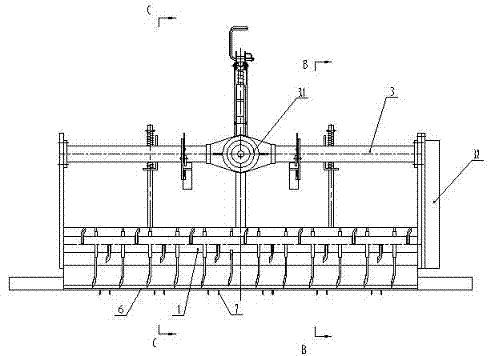

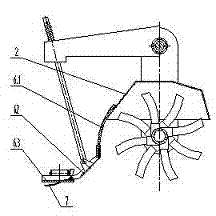

[0052] Such as figure 1 , figure 2 The shown paddy field stubble tiller includes a rotary paddle mechanism 1, a casing 2, a transmission system 3, a suspension assembly 4, a frame assembly 5, and a carriage assembly 6; the transmission system 3 includes Two-stage transmission mechanism, the former stage is the bevel gear transmission mechanism 3.1 in the middle of the cultivator, and the latter stage is the chain transmission mechanism 3.2; the drag plate assembly 6 is connected to the rear end of the casing 2; the chain transmission mechanism 3.2 Set on one side of the tiller, the bevel gear transmission mechanism 3.1 transmits the power to the chain transmission mechanism 3.2 through the transmission shaft, and the chain transmission mechanism 3.2 transmits the power to the rotary paddle mechanism 1. In this embodiment, the chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com