Disposable condenser discharge projection welding process for nozzle and body of stainless steel kettle

A capacitor energy storage, one-time technology, used in energy storage discharge welding, resistance welding equipment, welding power sources, etc., can solve problems such as poor welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below we further elaborate the present invention in conjunction with accompanying drawing,

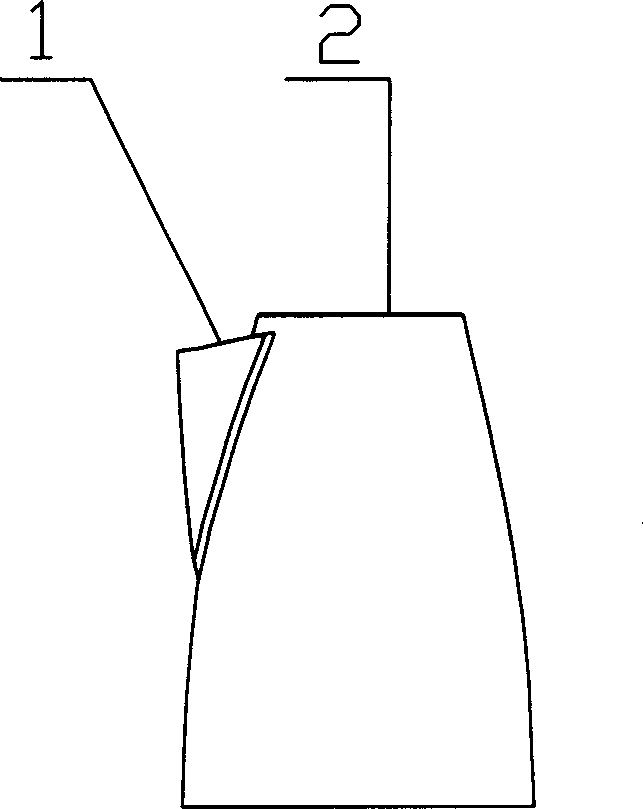

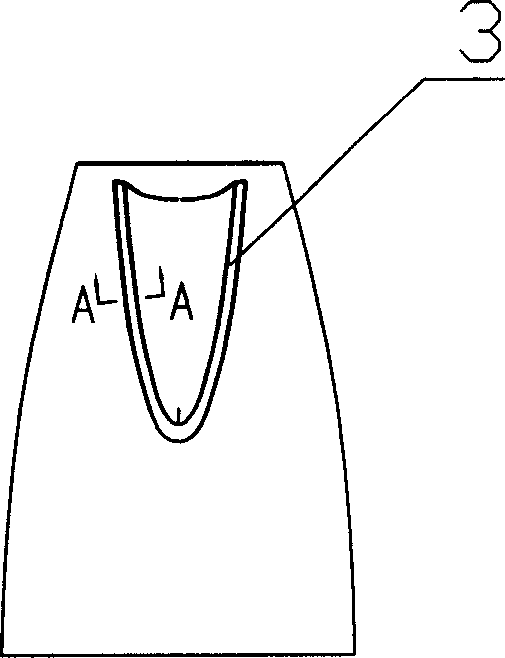

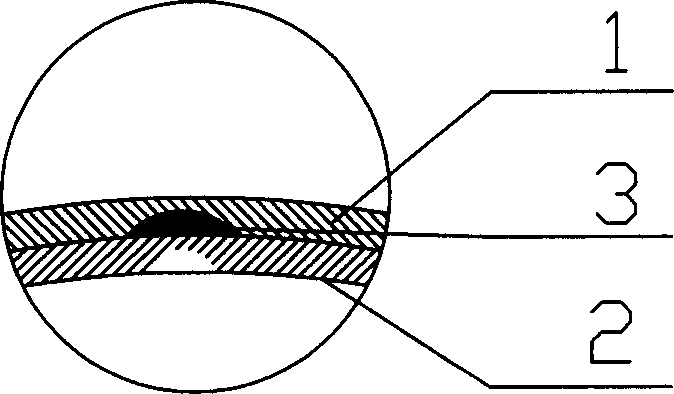

[0021] Such as figure 1 , figure 2 Shown is the stainless steel pot body and spout that need to be welded, of which figure 1 The welding seam between the spout and the body of the middle spout is long, 240MM, and the thickness of the plate is 0.6mm. For this reason, we choose a capacitor energy storage welding machine with a capacity of 35000J. For the structural diagram of the welding machine, see image 3 , Figure 4 . In order to achieve the ideal welding effect, we strictly follow this welding process:

[0022] 1. We pre-bump the welded surface of the optional stainless steel pot body as a whole, see figure 1 shown;

[0023] 2. According to the curved surface shape of the embossed pot body and spout, process the upper and lower electrode heads that completely match the surface of the pot body and spout to be welded; ensure that the upper and lower electrode heads are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com