High-performance radial tire intelligent vulcanizing machine

A radial tire and vulcanizing machine technology, applied in the field of tire production machinery, can solve the problems of uneven buffer force, weak positioning, impact, etc., and achieve the effect of strong and durable adjustment mechanism, improved vulcanization efficiency, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

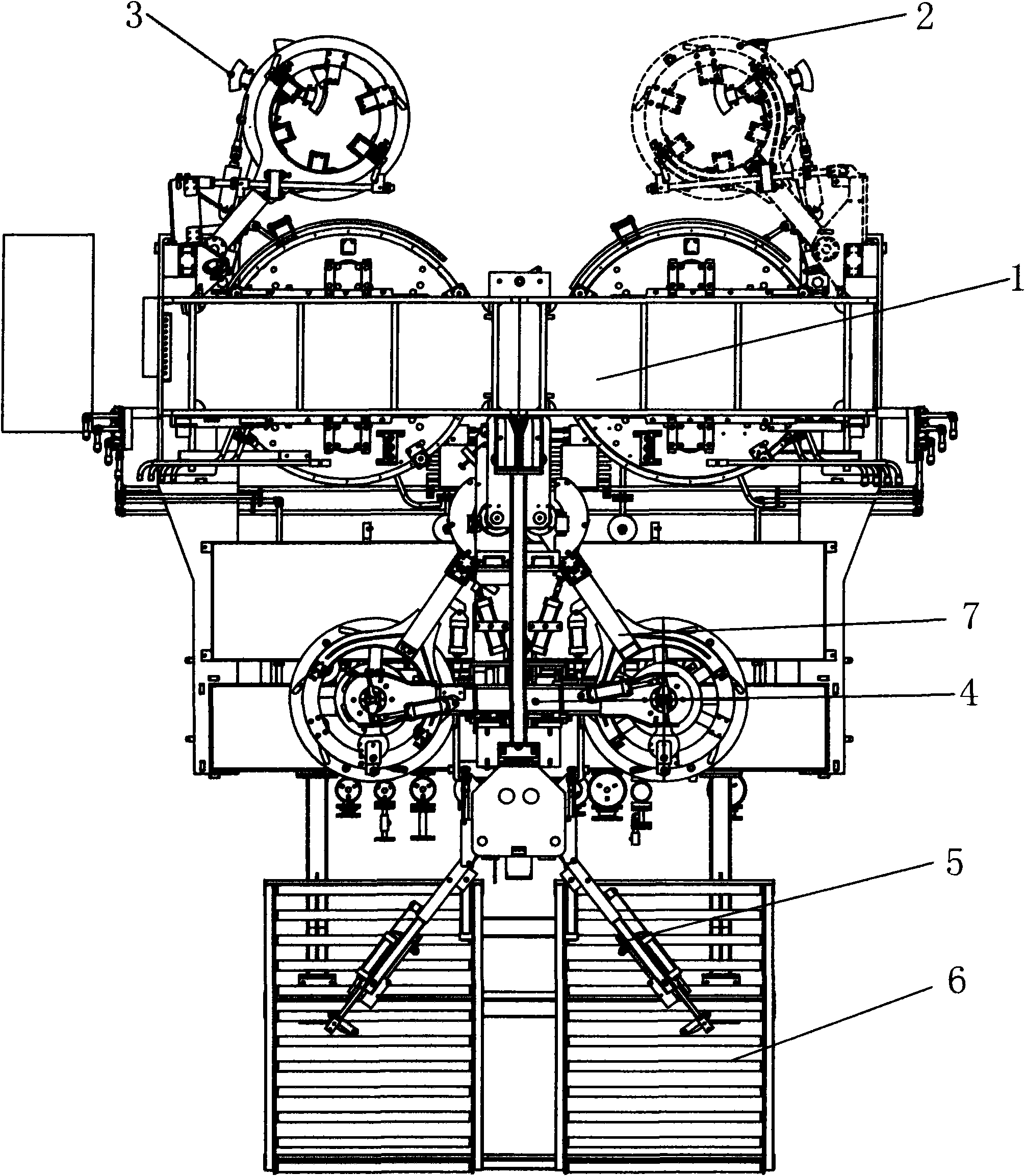

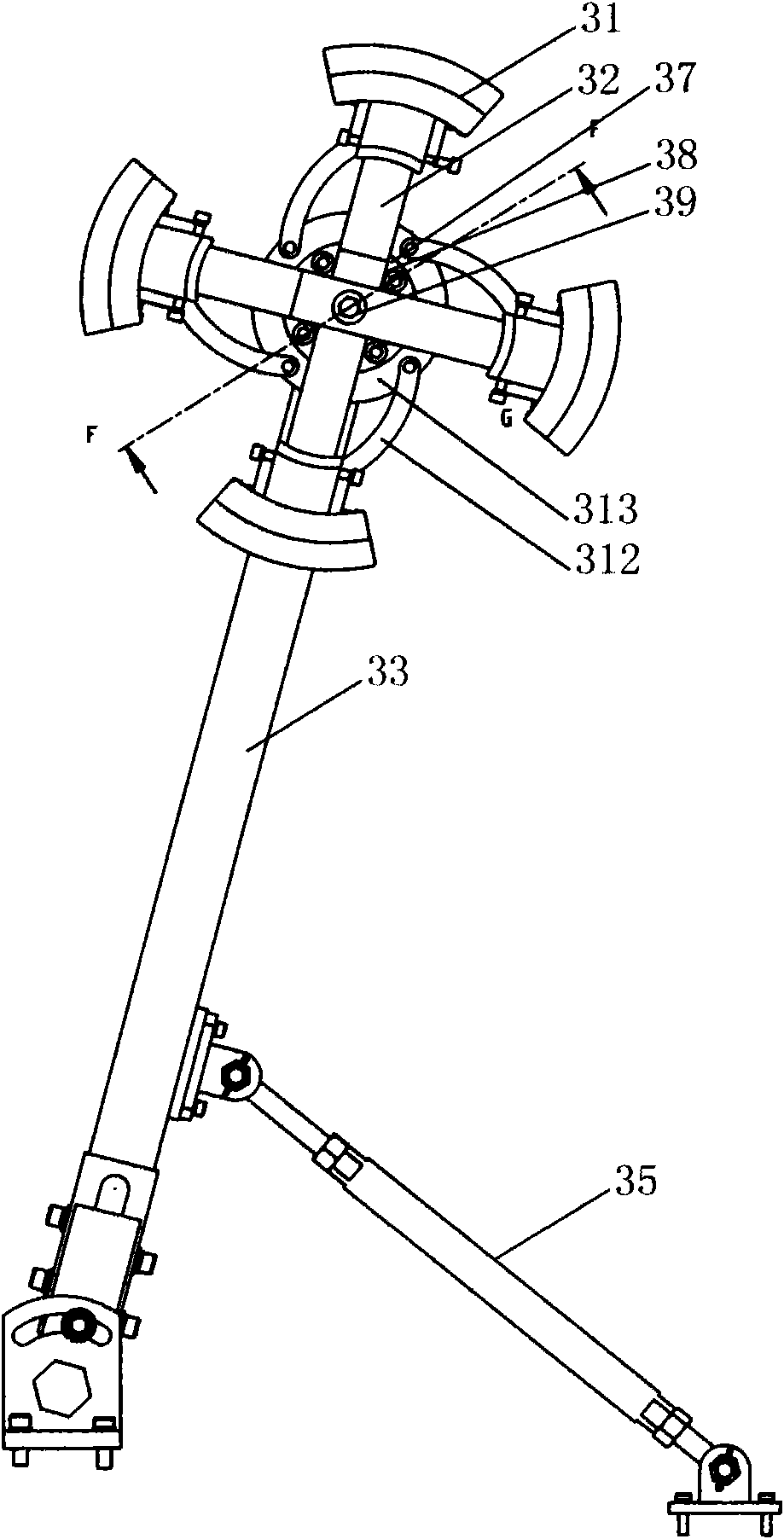

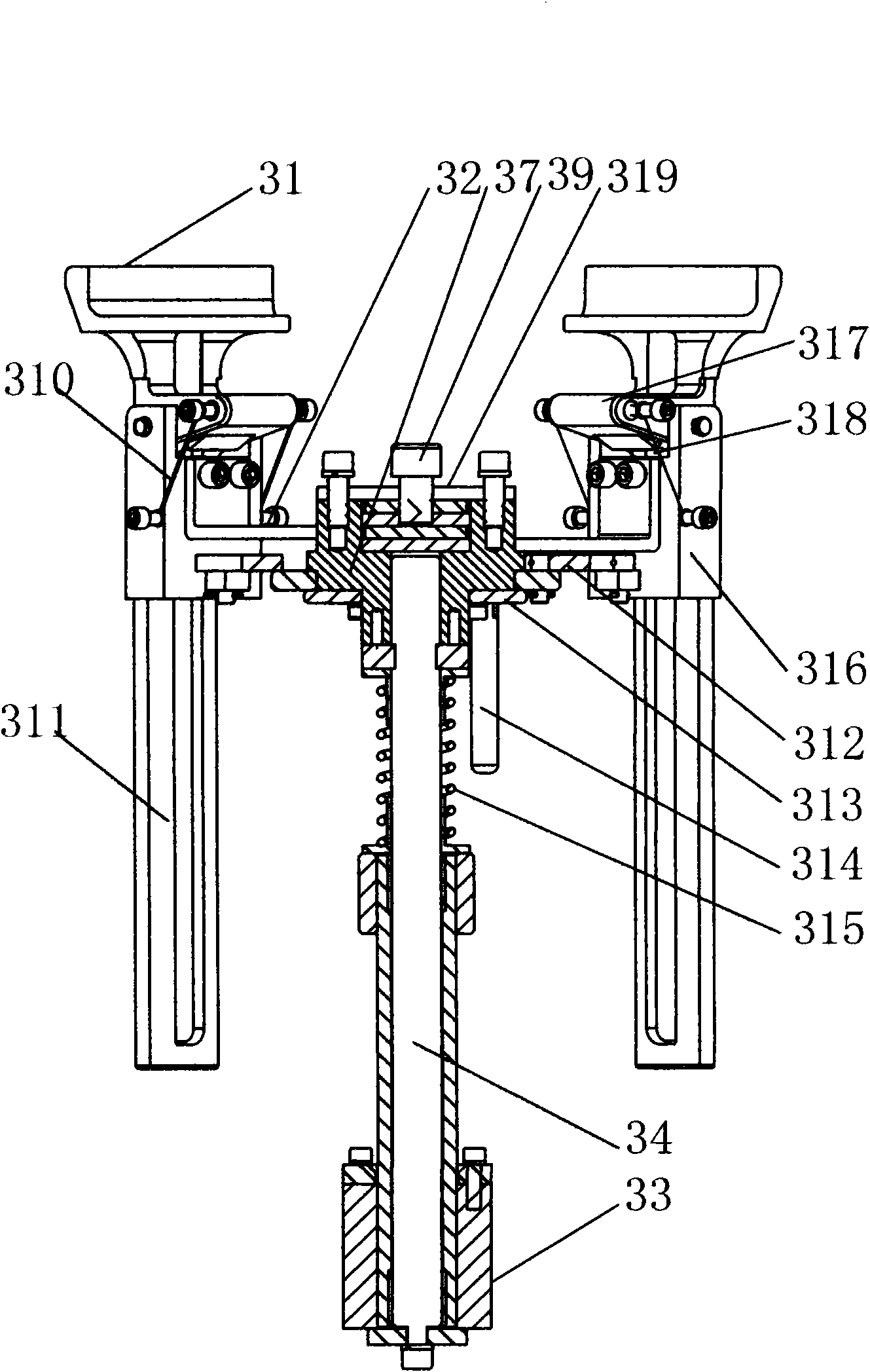

[0031] A high-performance radial tire intelligent vulcanizing machine, including a frame 1, a tire loading manipulator 2, a pressurizing mechanism, a vulcanizing chamber, a mold opening and closing mechanism, a central mechanism, a movable mold driving device, an intermediate manipulator 7, and a two-station four-point type The rear inflation device 4, the tire unloading manipulator 5 and the connecting roller table 6, the frame 1 is a frame-type overall structure, the lifting mechanism of the mold opening and closing mechanism is guided by needle rollers, and the front end of the frame 1 is set There is a tire storage mechanism 3. First, the raw tire is placed on the tire storage mechanism 3, and the tire loading manipulator 5 grabs the raw tire to the vulcanization mechanism for vulcanization. The station four-point post-inflation device 4 is cooled and shaped, and then the tire unloading manipulator 5 grabs it to the connecting roller table 6 and transports it to the corresp...

specific Embodiment 1

[0040] Specific embodiment 1: comprise elevating mechanism, height detecting device, turn in and turn out mechanism and manipulator, height detecting device detects the height of elevating mechanism, manipulator joins with elevating mechanism by rotating arm 23, and one end of described rotating arm 23 is fixed Installed on the manipulator 25, the other end is connected with the carriage 27 through the bearing 212. Described elevating mechanism comprises two vertically arranged frame bodies 214, is positioned at the linear guide rail 22 on the frame body 214, slide frame 27 and the lifting oil cylinder 21 that joins with slide frame 27, described slide frame 27 and linear guide rail 22, and move up and down along the linear guide rail 22; the described turning-in and turning-out mechanism includes a guide rod 26, a rotating block 28, and a turning-in and turning-out cylinder 29, and one end of the guide rod 26 is connected to the carriage 27, and the The guide rod 26 is hinged...

specific Embodiment 2

[0042] Embodiment 2: The height detection device includes a chain fixed on the vulcanizer, and a sprocket engaged with the chain. A rotary encoder is arranged on the sprocket, and the sprocket is located on the carriage 27 . All the other parts are identical with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com