Tire vulcanizing temperature measuring method

A technology of tire vulcanization and thermometer, which is applied in the field of tire manufacturing, can solve the problems of complex vulcanization temperature measurement method and low accuracy of vulcanization temperature measurement value, and achieve the effect of simple structure, high accuracy and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A tire vulcanization temperature measurement method is characterized in that it comprises the following steps:

[0030] 1) Select the green tire to be vulcanized and measure temperature;

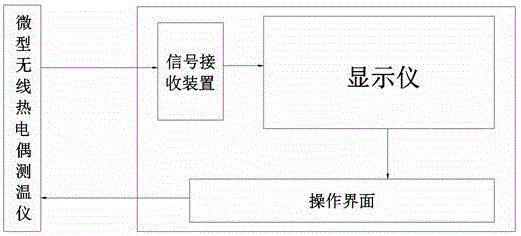

[0031] 2) Embed a miniature wireless thermocouple thermometer in the tire blank selected in step 1 for vulcanization temperature measurement, and at the same time, set up a processing device;

[0032] 3) Complete step 2), confirm that the relevant equipment and instruments are working normally, and select the required data processing function items on the processing device, start mold clamping and vulcanization, monitor the vulcanization time and temperature changes of the tire green during the vulcanization process in real time, and Received signals, recording, summarizing and analyzing;

[0033] 4) After step 3) vulcanization is completed, cut the tire and take out the miniature wireless thermocouple thermometer for secondary use.

Embodiment 2

[0035] A tire vulcanization temperature measurement method is characterized in that it comprises the following steps:

[0036] 1) Select the green tire to be vulcanized and measure temperature;

[0037] 2) Embed a miniature wireless thermocouple thermometer in the tire blank selected in step 1 for vulcanization temperature measurement, and at the same time, set up a processing device;

[0038] 3) Complete step 2), confirm that the relevant equipment and instruments are working normally, and select the required data processing function items on the processing device, start mold clamping and vulcanization, monitor the vulcanization time and temperature changes of the tire green during the vulcanization process in real time, and Received signals, recording, summarizing and analyzing;

[0039] 4) After step 3) vulcanization is completed, cut the tire and take out the miniature wireless thermocouple thermometer for secondary use.

[0040] The thermocouple in the miniature wireles...

Embodiment 3

[0045] A tire vulcanization temperature measurement method is characterized in that it comprises the following steps:

[0046] 1) Select the green tire to be vulcanized and measure temperature;

[0047] 2) Embed a miniature wireless thermocouple thermometer in the tire blank selected in step 1 for vulcanization temperature measurement, and at the same time, set up a processing device;

[0048] 3) Complete step 2), confirm that the relevant equipment and instruments are working normally, and select the required data processing function items on the processing device, start mold clamping and vulcanization, monitor the vulcanization time and temperature changes of the tire green during the vulcanization process in real time, and Received signals, recording, summarizing and analyzing;

[0049] 4) After step 3) vulcanization is completed, cut the tire and take out the miniature wireless thermocouple thermometer for secondary use.

[0050] The thermocouples in the miniature wirele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com